Wholesale and Custom Cutting Boards

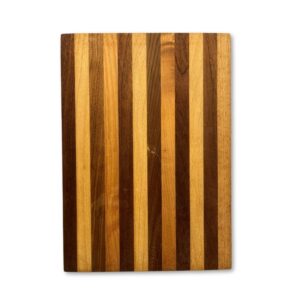

Find out the finest cutting boards in our catalog below. Discover them in ranging sizes and shapes with unique, user-friendly features. The cutting boards are made from acacia, teak, ironwood, or sapele: LeeKnives only work with deluxe, natural hardwood that provides great resistance to daily use.

We offer trending end-grain chessboard grid cutting boards; customizable UV printed cutting boards; cutting boards in sets for different tasks; as well as the classic plain-surface options.

Showing all 7 results