刃物業界に携わる方なら、陽江という地名をご存知でしょう。「刃物と鋏の都」と呼ばれていますが、これは単なるスローガンではありません。1500年以上にわたる努力の末に築き上げられた称号なのです。.

この歴史を理解することで、ここで作られる製品に込められた価値を理解することができます。それは、パートナーとして得られる品質と信頼性に直接影響を与える、技術、テクノロジー、そして貿易の物語です。.

概要を簡単にご理解いただけるよう、業界を形成した重要な出来事の簡単な年表を以下に示します。.

楊江ナイフの歴史

| 期間 | 主要人物 / イベント | 今日のビジネスにとって何を意味するのか |

| 南北朝時代(420年~589年) | 仙夫人が北方の鉄の技術を紹介。. | 品質の基盤: この地域の金属加工に関する深い知識はここから始まりました。. |

| 隋・唐時代(西暦581-907年) | フォン・アン将軍が「蘇鋼」を開発。“ | 高性能の起源: 焦点は、より強く、より弾力性のある鋼合金の開発に移りました。. |

| 宋代(960年~1279年) | 海上シルクロードは道具作りを促進します。. | 建物の規模とスキル: 貿易からの高い需要により、大規模生産の能力が構築されました。. |

| 清朝後期(1875-1908) | “「アイアン・アレー」が工芸の中心地として形成されます。. | 成熟したサプライチェーン: 最初の産業クラスターが誕生し、専門家のネットワークが構築されました。. |

| 共和国時代(1912-1949) | He QuanliやJifuなどの最初のブランドが登場します。. | 早期市場認識: 職人たちはエンドユーザーとブランドの評判について考え始めました。. |

| 近代(1983年~現在) | Shibazi Zuo の台頭と OEM/ODM への注力。. | 世界の製造力: 陽江は世界のナイフサプライチェーンの中心地となる。. |

卸売ナイフを購入して、今すぐ私たちと一緒にスケールアップを始めましょう

弊社にお問い合わせいただき、営業担当者と連絡を取り、無料の見積もりを入手してください。

深く根付いた工芸の伝統

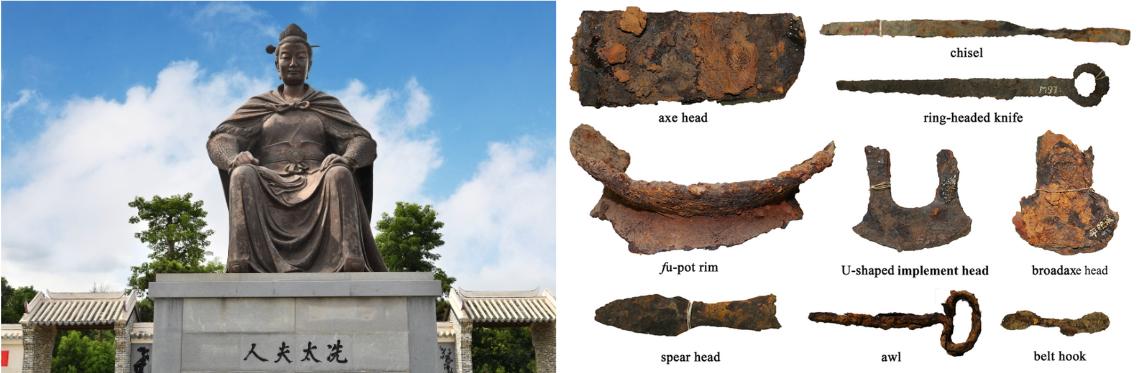

1. 礎:仙夫人と初期の鉄器技術(南北朝時代、420~589年)

物語は、北方から高度な製鉄技術をもたらした地元の指導者、仙夫人(512~602年)から始まります。この技術には、より効率的な炉と、脆い鋳鉄を加工しやすい錬鉄や初期の鋼鉄に変える優れた方法が含まれていました。彼女の工房では優れた武器や農具が作られ、この地域は金属加工の中心地となりました。.

- これがあなたにとって重要な理由: これが「0から1へ」の瞬間でした。陽江は金属加工の場としてだけでなく、金属を極める場所として確立されました。その深い知識は今もなお、ここに息づいています。.

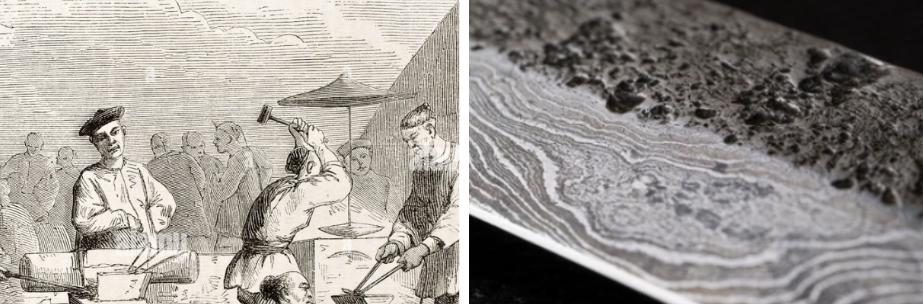

2. パフォーマンスの飛躍:馮昊将軍の「蘇鋼」(隋・唐時代、西暦581~907年)

仙夫人の孫である馮安将軍は、これをさらに一歩進めました。彼と鍛冶屋たちは、地元では「苏鋼」(苏钢)として知られる精錬鋼を開発しました。これは鍛接鋼の初期の形であり、硬い(高炭素)鉄と柔らかい(低炭素)鉄の層を叩き合わせて作られました。この工程によって不純物が除去され、鋭い刃を保つのに十分な硬さと、欠けたり折れたりしにくい十分な強度を兼ね備えた刃が生まれました。これは、かの有名な「苏安」によく似た、初期の複合刃物でした。 ダマスカス鋼.

- これがあなたにとって重要な理由: これは、基本的な工具の製造から高性能合金の開発への移行を象徴しています。今日の製品にとって不可欠な、より優れた材料と熱処理の追求は、約1400年前にここから始まりました。.

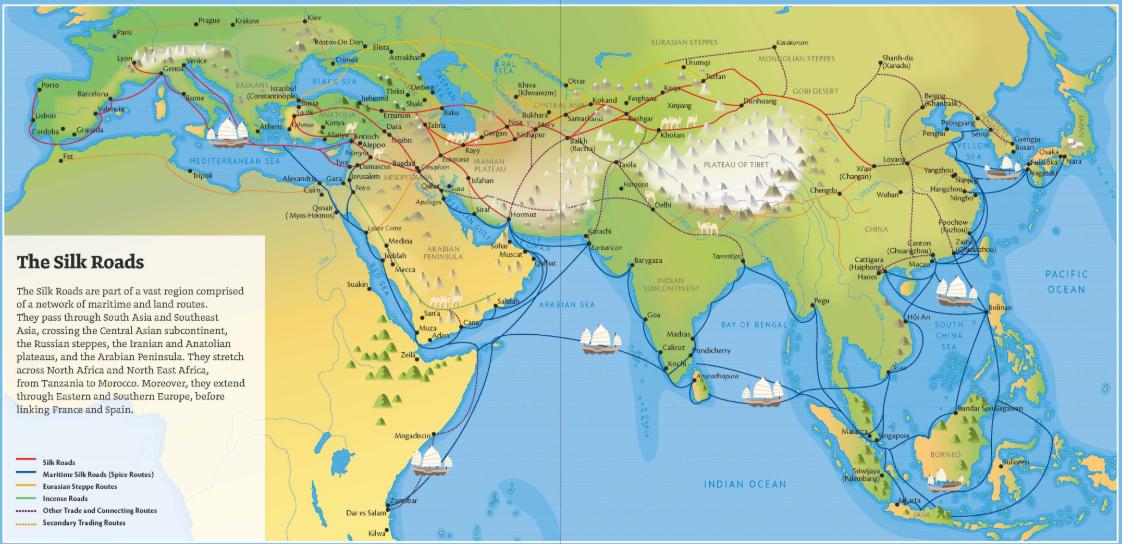

3. 貿易の中心地:シルクロードの成長を促進(宋代、960~1279年)

海上シルクロードの要衝であった陽江(当時は高梁港の一部)は、陶磁器や鉄などの商品の積み替え拠点として栄えていました。巨大な造船産業は、高品質の斧、鋸、ノミの安定供給を必要としていました。耐久性のある道具に対する地元の旺盛な需要は、鍛冶屋の労働を支え、生産効率の向上を促しました。.

- これがあなたにとって重要な理由: 貿易によって産業は規模拡大を余儀なくされました。この地の職人たちは、大量生産と高強度化を両立させる工具の生産方法を早くから習得しました。これは現代の製造業の直接の祖先と言えるでしょう。.

4. 産業集積:「鉄街」の形成(清朝後期、1875年頃~1908年)

19世紀後半までに、刃物産業は高度に集中化しました。歴史記録には、街の寺院の近くに「打铁巷(アイアン・アレー)」として知られた特定の地域が記されています。この通りには、それぞれ異なる工程に特化した小さな鍛冶屋や工房が立ち並んでいました。これが真の産業集積地の形成に繋がり、知識の共有と品質に対する高い評価が地域全体に広まりました。.

- これがあなたにとって重要な理由: これが陽江サプライチェーンの誕生です。この初期の専門化が、今日活用できる効率的で多層的な製造エコシステムの基盤となっています。.

ローカルワークショップからグローバルパートナーへ

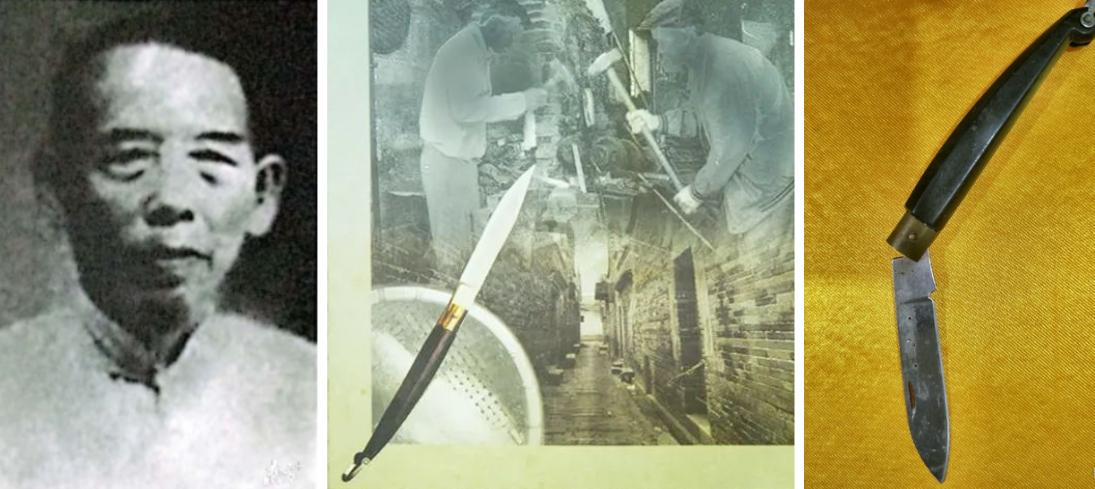

1. 初期のブランドと品質への評判(共和国時代、1912-1949年)

20世紀初頭には、特定のメーカーが名声を獲得し始めました。 何泉里 キッチンナイフは、その切れ味の鋭い鋼でレストランで有名になりました。1930年代頃、梁継富という職人が、 “「ジフナイフ」” シェービングに十分な精度と耐久性を備えた独自の刃先が評価され、世界博覧会で賞を受賞しました。.

- これがあなたにとって重要な理由: これがブランド思考の始まりでした。メーカーは自社の名前を品質や具体的な性能特性と結びつけるようになり、これは今日でも成功しているOEM工場が実践している原則です。.

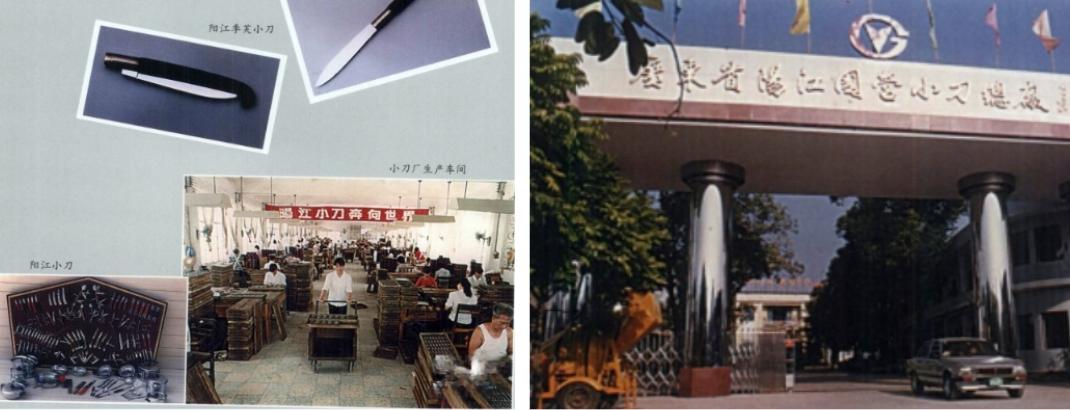

2. 国有時代:輸出向け建設(1955~1980年代)

1955年以降、刃物産業は国営協同組合へと再編され、後に陽江県国営刃物工場が設立されました。この動きにより、数百の小規模な工房が統合され、大規模な生産拠点となりました。1960年代までに、この工場は主要な輸出業者となり、刃物を国際市場に送り出し、世界初の貿易チャネルを確立しました。.

- これがあなたにとって重要な理由: この期間に、大規模かつ標準化された生産のための基盤が構築され、国際物流と品質への期待に応えるための基本的な経験が確立されました。.

3. 近代産業への3つの飛躍(1990-2001)

20 世紀末は急速な変化の時代であり、今日見られるようなダイナミックな民間所有の産業が誕生しました。.

| 飛躍 | 期間 | コアの変更 | あなたにとっての結果 |

| 最初の飛躍 | 1990年代 | 手動から半機械化へ | 生産がより効率的かつ一貫したものとなり、より大きな輸出注文に対応できるようになりました。. |

| 第二の飛躍 | 1997 | 民間工場の台頭 | 競争により品質と顧客重視の姿勢が高まり、ダイナミックで革新的な市場が生まれました。. |

| 第三の飛躍 | 2001 | グローバル貿易の受け入れ(WTO) | 工場は、世界的なブランドの OEM/ODM 専門企業になるために、設備に多額の投資を行いました。. |

今日の品質を推進するテクノロジー

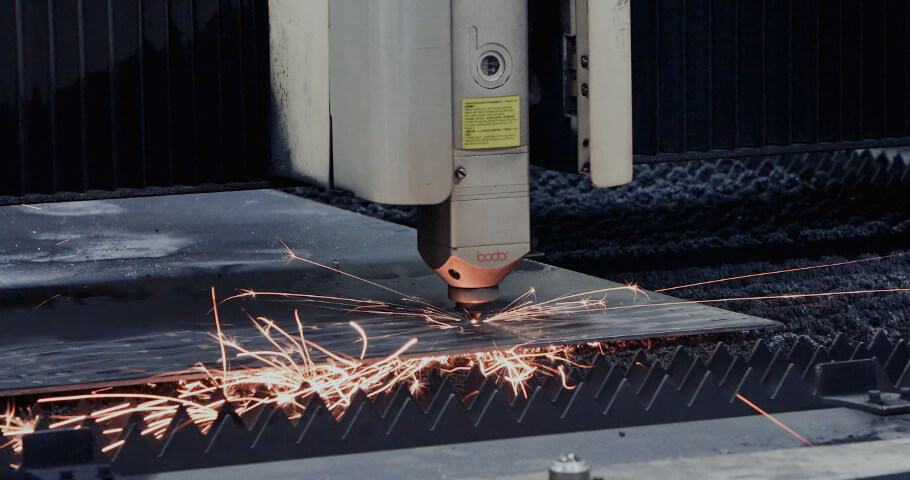

「第三の飛躍」は製造工程の抜本的な改革でした。世界的ブランドの厳しい基準を満たすため、陽江の工場は技術に多額の投資を行いました。主な投資は以下のとおりです。

- 自動化機械: 高精度スタンピングプレス、CNC(コンピュータ数値制御)研削盤、レーザー切断システムにより完璧な一貫性を保証します。.

- 高度な熱処理: 現代の鋼材の性能を最大限に引き出すために不可欠な、正確な温度制御を実現する真空熱処理炉。.

- グローバルスチールの習得: 国際的なパートナー、特に米国市場へのサービス提供のため、当社は世界規模の鋼材ラインナップを充実させる技術開発に多額の投資を行いました。これには以下が含まれます。

この専門知識と、自動化された CNC 機械および精密な真空熱処理を組み合わせることで、お客様の正確な仕様に合わせたナイフを製造することができます。.

卸売ナイフを購入して、今すぐ私たちと一緒にスケールアップを始めましょう

弊社にお問い合わせいただき、営業担当者と連絡を取り、無料の見積もりを入手してください。

今日の陽江:サプライチェーンの中核

この1500年の歴史は、他に類を見ない製造業のエコシステムを築き上げてきました。数字がそれを物語っています。.

楊江ナイフ:スナップショット

| メトリック | データ | なぜそれがあなたにとって重要なのか |

| 企業数 | 2,600人以上 | 原料鋼から梱包までの完全なサプライチェーンがここにあります。. |

| 年間生産額 | 520億円以上 | この規模により、安定性と驚くべきリソースへのアクセスが実現します。. |

| 中国の生産量のシェア | 70% 中国製のナイフのうち | 業界の重心はここにあり、イノベーションと才能を推進しています。. |

| 中国の輸出シェア | 85% 中国から輸出されたすべてのナイフのうち | 当社は国際的な品質基準を満たす比類のない経験を持っています。. |

陽江の主要ナイフブランド

陽江ブランドを見ると、業界の二つの側面が見えてきます。.

消費者市場向け: Shibazi Zuo (十八子作)

1983年に李家によって設立されたShibazi Zuoは、陽江に近代的な大量生産技術をもたらした企業です。中国国内で最も有名なナイフブランドであり、国内市場をリードしています。.

あなたのビジネスのために: 専門OEM/ODMパートナー

石巴子左は有名ですが、あなたのようなグローバルブランドにとって陽江の真の原動力は 数百の工場 店頭では見かけないような、そんなナイフを。それが私たちLeeKnivesのようなOEM/ODMのスペシャリストです。私たちは、グローバルブランドのナイフの設計と製造に特化しています。私たちは世界のナイフ市場の屋台骨です。私たちの強みは次のとおりです。

- コンセプトから納品までシームレスに: 完成したデザインでも、アイデアだけでも、 社内デザイナーチーム エンジニアがお客様と連携し、設計図の最適化、適切な材料の選定から最終的な製造、品質管理まで、ワンストップの包括的なソリューションを提供します。.

- 陽江のコスト + 米国の効率: 私たちは両方の長所を兼ね備えています。お客様のナイフは、Yangjiangの成熟したサプライチェーンのコスト優位性を活かして製造されていますが、 米国に拠点を置く倉庫 複雑な物流をお客様に代わって処理します。これにより、製品は迅速かつ確実に市場に届けられ、在庫の逼迫や配送の煩わしさを軽減します。.

- 深い市場洞察: 当社は長年にわたり、 OEMサービス 著名なアメリカブランド向けに製品を提供しています。私たちはアメリカ市場を深く理解しており、特にエントリーレベルおよびミッドレンジ市場の消費者が真に価値を認め、購入する製品を生み出すために、性能、コスト、そして職人技のバランスをどのように取るかを熟知しています。.

Leeknivesと提携することで、単にナイフを調達するだけでなく、事業の拡大、革新、そして競争の激しい市場での成功を支援する戦略的パートナーを得ることができます。.

優れた製造業の伝統を持つパートナー

この歴史は単なる物語の集積ではありません。ここのサプライチェーンがこれほどまでに深く、熟練した、そして信頼できるものである理由なのです。.

で LeeKnives.com, 私たちは、この長い伝統の現代的一翼を担っています。何世代にもわたる知識と最新の設備を駆使し、お客様のブランドを築くナイフを製造しています。.

ナイフ業界の中心から次の製品ラインを調達する準備はできていますか? 製造ニーズについてご相談いただくには、弊社までお問い合わせください。.