Modern Damascus steel, in a nutshell, is the consequence of several types and layers of steel folded and forge-welded. The forging technique that produces Damascus steel results in the unique and varying patterns. Thus, it is also called pattern-welded steel.

The best way to think of it is like making puff pastry. Heat it, hammer it, fold it, pattern weld it, and do it repeatedly until you get tens or even hundreds of layers of steel with really aesthetic wavy patterns.

Blades made of Damascus steel, however, have been around for centuries. What is Damascus steel back then, and how is it different from what we known now?

Origin of Damascus steel

Damascus is derived from the city of Damascus, the capital of Syria.

At that time, Damascus imported Wootz steel from Persia and Sri Lanka to manufacture and use hybrid steel blades known for their toughness and edge retention. The developers understood that through a particular combination of different metals, higher-quality weapons could be crafted.

They knew that a blade that is only made of hard steel has the disadvantage of breaking easily. Therefore, the blade meets two basic requirements of knife steel.

On the one hand, it is flexible and not quite prone to breaking during heavy-duty use. And, on the other hand, it is hard enough with a sharp edge that helps it maintain the degree of sharpness for a long time.

What was original Damascus steel made of?

As earlier mentioned, the original Damascus steel during its early periods was forged from ingot (a solid block) of wootz steel.

Unfortunately, the production of genuine Damascus steel lasted for only 11 centuries. It was only reproduced not until recently. But the modern Damascus replications don’t have the same market anymore. The word ‘Damascus steel’ was gradually taken over by pattern-welded steel instead. Which we will be discussing more in below.

The modern-day reinvention process of Damascus steel

In 1981, according to the NYTimes, two scientists from Stanford University researching the superplastic characteristics of metal reportedly discovered the secret of how the real Damascus steel was made.

Their research showed that the kind of steel used to create the ancient Damascus steel required high carbon and low temperature during the hammering and forging process. It is then followed by rapid heat increase and then rapid cooling.

This discovery has reshaped the modern production of this steel. Today, as much as 1.8% carbon content is now introduced into Damascus steel production.

In addition, the temperature for forging is only about 1,500 to 2,000 degrees Fahrenheit, 900 degrees less than what’s required for most other types of steel.

What is Damascus steel made of now?

Damascus steel, today, is mostly made of a variety of different steel followed by the pattern-welding technique. The carbon steel gives the blade a sharp edge, while the stainless steel variant has a high resistance to oxidation and rust.

Pattern-welded Damascus steel is produced in complex processes. It’s now made from accompanying elements such as manganese, silicon, sulfur, phosphorous, nickel, and carbon.

Today’s industry uses a variety of forge-welded metals and irons to manufacture Damascus steel, with proportions and variety of the metals varying from manufacturer to manufacturer.

The small, wavy indentations on the surface result from the acid-etching process, while the forging process forms the patterning of the actual steel.

Buy Wholesale Damascus Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

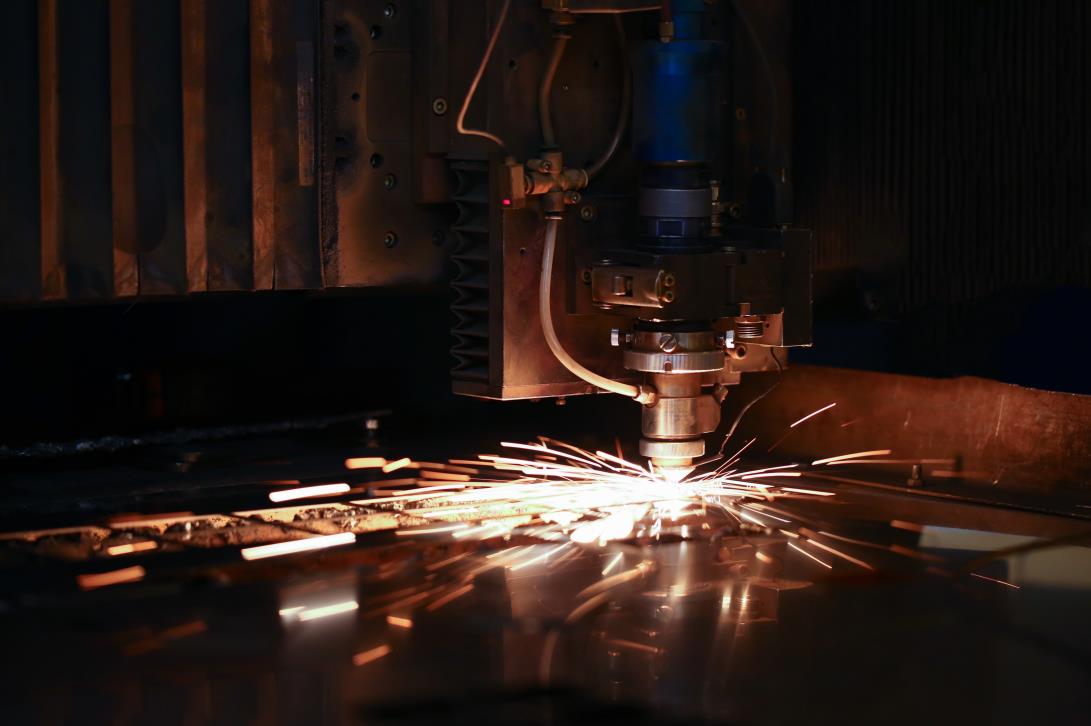

How to make pattern-welded Damascus steel?

The material used on pattern-welded Damascus steel consists of layers of different steels forged together. Much more than just two layers are used today than was the case with the original method.

The process is called pattern welding. It involves refining metal alloy with successive hammering, folding, stretching, cutting, and forging together. If you repeat this process several times, you get steel from hundreds of layers of Damascus steel.

Several layers, usually 2 to 5, are placed on top of each other and welded in a forge. The composite is then separated, stacked, and forged again. The whole procedure is repeated several times.

Since the number of layers doubles after each stacking, you can end up with tens or hundreds of layers after just a few repetitions.

The main difficulty with forge welding is that the material must not exceed a certain temperature; otherwise, the carbon will burn. And at the same time, the material must not scale (oxidize) as it would no longer be forged together.

When the steel starts to burn (oxidation) before the melting point, towards the end of the heating, quartz sand or borax is sprinkled on the area to be welded. This melts into a liquid glass layer and thus protects the steel from oxygen. The right time to do this is when the first sparks of burning carbon appear.

A glassy shield is created that encloses the two parts to be welded. This serves as protection and as the time pass, allowing the smith to carry the welded parts to the anvil and join them there with a precise blow.

To obtain beautiful patterns on the surface, the steel can be twisted. Depending on the carbon content or alloy, the different layers turn light (nickel) or dark (manganese) in acid. The cutting edges are then usually post-hardened at the end.

Damascus steel variants

There are three known variants of Damascus steel.

Original Damascus steel

The first one is the original Damascus steel or wootz steel, using a rare type of metal sourced from India during the middle ages. The real Damascus steel is often referred to as crucible steel as it was melted in a crucible, a kind of heat-resistant vessel made of clay.

Blacksmiths melt the Indian wootz steel – in addition to plant matter and materials such as glass – in the crucible. Crucible steel is, therefore, the term given to any steel produced by this method.

Modern Damascus steel replications

The modern Damascus replications are produced by a small number of blacksmiths. Although the original ore mined from India was lost, the metallurgists recreated ore with the same composition that was used to make the original wootz steel.

Pattern-welded Damascus steel

Pattern-welded Damascus steel is a completely different story. They are produced following the pattern-welding technique where the steels are melted, hammered, rolled, cut, stacked together. This process is repeated as many times as possible to achieve as many layers as possible and a unique wavy pattern.

What is Damascus pattern?

Damascus patterns are created by welding high carbon and stainless steel (or any two other steel combinations) into a twisting and folding form. Therefore, it is necessary to use carbon steel and steel with a high nickel content (or pure nickel).

There are several manufacturing processes, but each method will create a distinctive wavy pattern. In addition, the metal, made of many folds, will give the blade strength and durability.

Patterns on Damascus steel can vary: from waves and spirals to curls and a watery look. However, it’s hard to make two blades. The manufacturing process leaves room for the mystery of metallurgy and the blacksmith’s creativity.

How does the pattern of the Damascus steel come about?

Patterns in Damascus steel vary depending on how the craftsman works with the workpiece. Using two alternating types of steel, the blacksmith heats, twists, and stacks metal layers to create vibrant patterns.

Treating the knife blade with acid only makes the characteristic blade pattern visible. The pattern is created because when the blade is immersed in the acid, the soft iron parts are attacked a little faster than the hard steel parts. The acid also causes the gray color.

Damascus steel patterns can end up white or shiny, some in shades of gray, and some in black. Therefore, experienced blacksmiths can create many different patterns when forging. Next, the blade must be hardened.

Damascus steel applications

Damascus steel is used in many areas. Especially in the manufacture of kitchen knives, primarily for professional chefs, of course. However, the steel is also used to manufacture various hunting knives or pocket knives. In addition, as already explained, Damascus steel was often used in the manufacture of swords.

Pocket knives

Damascus pocket knives are handy. They are used when camping or fishing. Its size and low weight are ideal for carrying the knife in a backpack or on a belt.

Kitchen knives

These are the most common tools made of Damascus steel. Damascus kitchen or chef’s knives are designed for use in the kitchen and are very sharp. You can use them effortlessly to cut fish, meat, and vegetables.

Sword/katana

Swords or katanas equipped with Damascus blades – which Europeans discovered during the Crusades – were long considered the best in the world. According to a legend, a damascus steel saber would have been able to cut in two a silk handkerchief floating in the wind… A feat that no European weapon would have equaled.

There are, however, Damascus steel swords in existence today. An example is the Damascus Steel Viking Sword which consists of 512 layers of Damascus steel.

Apply Damascus steel on kitchen knives, swords, pocket knives, and more with LeeKnives. Our OEM service will customize a star product for you.

Manufacture Your Own Damascus Knives with Us Today

Contact us and connect with a sales rep to get a free quote.

Is Damascus knife a good niche for business?

Damascus knives, despite blacksmiths and manufacturers losing the means of production, Damascus knives are well in fashion today and in high demand. So, it’s a good niche to focus on.

Customers highly demand Damascus knives for use in the kitchen, for craftwork, and for fishing in the form of pocket knives.

They are also used by survivalists and fighters due to their durability and high strength. It’s also sought after by knife collectors due to its high aesthetic designs and varying patterns you can get.

Best Damascus knife brands

Various manufacturers and brands – more or less well-known or unknown – offer knives made of Damascus steel. Below are the three well-known manufacturers of Damascus knives:

Zwilling

Zwilling, the manufacturer from Germany, is one of the leading manufacturers of household knives and kitchen cutlery. The company’s damascus knives have a sweeping design and an ice-hardened blade.

It has damascus knives made from one piece and handles made of riveted wood and plastics. The Kramer Euroline stainless Damascus Collection is one of the best Zwilling Damascus steel knives.

Shan Zu

From the Far East comes this knife manufacturer that has grown to become a favorite of knife dealers and customers. They have damasucs knife sets that offer you the ideal basis for those who work in the kitchen and outdoor.

The brand has up to 20 Damascus knives in its catalog, ranging from bread knives to paring knives, santoku knives, boning, slicing, and steak knives. The SHAN ZU Chef’s Knife 8″ Damascus Knife is one of the best in its Damascus knife lineup. This knife is a high-quality all-round kitchen knife made from 67 layers of damascus and forged according to the classic, old Japanese Kai Shun tradition.

Kai

From Asia to Europe and the Americas, Kai has a firm grasp of the Damascus knife market with online stores dedicated to customers in these regions. From the Seki Magoroku to the Shun Classics, Kai has some of the best models on the market. But the KAI TDM Shun Premier Tim Mälzer damascus knife series is the highlight of the brand’s Damascus steel knife products.

It’s a knife that belongs to the series of the well-known chef Tim Mälzer. According to the manufacturer, the Damascus knife is made of 32 layers of corrosion-resistant Damascus steel and has a timeless design. The design of the blade results from the hand-worked hammered surface. This is called Tsuchime in Japan.

Final Words

Without Damascus steel, the world would certainly have developed differently. Many revolutions would never have happened or would have been fought with broken and bent swords. Instead, humankind has learned through tedious learning processes how a blade can be forged from conventional steel that can withstand the highest demands in battle.

Beware of fraud, however. Pattern-welded Damascus blades are extremely popular due to their excellent quality. But, the price of such a knife can be very high. This leads to dealers offering blades that only have the pattern etched. To simulate the pattern, thin sheets of metal are often welded onto both sides of the initial blade. It takes a lot of experience to distinguish the real Damascus blade from the fake one. So, it pays to deal with knife dealers that know their onions.

At LeeKnives, you can choose between different types popular steel including Damascus. Manufacture your own blade and start scaling up with us today.