Wholesale Pocket Knives

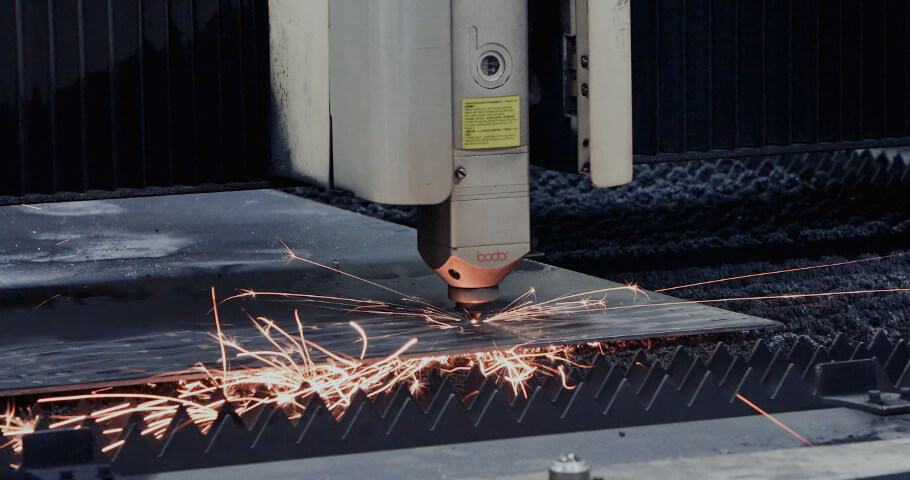

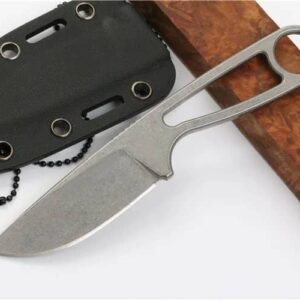

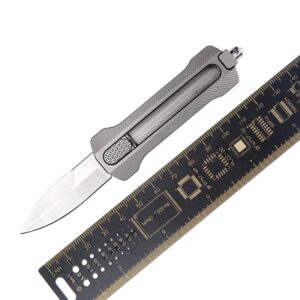

The following catalog are designs of pocket knives that we have crafted in the past, available for direct bulk purchase. These knives mostly feature 8Cr13MoV and D2 steel blade; however, you can opt for other alternatives like AUS-8, M390, and more. Each knife is unique with respective designs from tip to clip, as well as handle materials.

Showing 1–18 of 61 results