Sharpening a knife takes grinding off the edge to expose a new surface. Several sharpening tools accomplish this, with whetstones being one of the top choices.

Although sharpening works the same regardless of the tool utilized, whetstones stand out with their ability to achieve a sharp edge in a controllable way. For example, the user can adjust the sharpening angle, allowing them to give the knife the edge they want.

While honing rods and sharpeners can have similar results, which we’ll also cover in this article, knives are more complete after sharpening with a whetstone. Whetstones work as if they reset the cutting edge, making the blade as sharp as the first day.

In this article, we’ll go over everything you need to know about whetstones, the varieties you’ll find in them, and reveal the ones that make the best product to sell in your store.

Whetstone, water stone, and sharpening stone

Many often mistake whetstones for water stones. These two have different meanings, and the terminology is very simple.

Whetstone is a term that covers all sharpening stones. Water stone refers to whetstones that need water as a lubricant, such as the Japanese water stones. That said, all whetstones are sharpening stones, and water or oil stones specify a particular one.

Buy Wholesale Sharpening Tools and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

What’s a whetstone made of?

Whetstones are made from either natural or artificial materials. The natural ones are made from quartz, like the Arkansas stone or Japanese water stones. Artificial whetstones are made from abrasive chemical compounds. Silicon carbide or aluminum oxide are the two most common synthetic materials for producing sharpening stones.

Whether natural or artificial, whetstones have an abrasive surface that wears material from the knife’s edge with every stroke. How much material it removes depends on the grit size, which works the same as sandpapers – more on whetstone grits below.

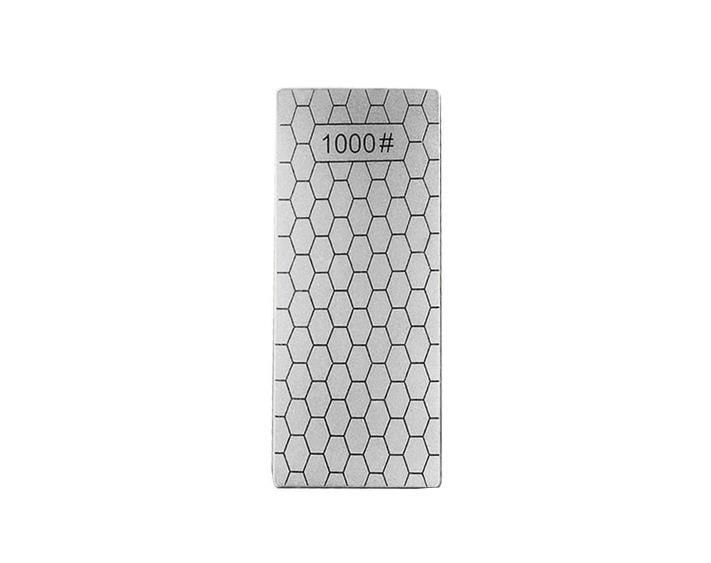

Other than novaculite, aluminum oxide, and silicon carbide, you’ll find whetstones with a coat of diamonds on a metal sheet. The diamond-coated whetstones are the coarsest and are designed to sharpen knives with good wear resistance. Unlike the others, these coarse sharpening stones often don’t require a lubricant. Here’s more to these and other popular options you have to present the best product to your customers.

Natural whetstones

Novaculite (Arkansas stone)

Novaculite is also known as Arkansas stone. Many of the novaculite produced today come from the Ouachita Mountains of Arkansas. That’s where it gets its name. The whetstones made from novaculite require oil in some form as a lubricant. It can be honing, mineral, or another type of oil suitable for sharpening.

Since novaculite is a natural material, oil stones usually lack a consistent grit size throughout. This can pose problems to users looking to give a specific edge to their knives. For example, they won’t be able to sharpen the edge fully at 3,000 grit.

Oil stones often miss the ability to create a sharp edge quickly. They have the tendency to polish/finish the edge as it sharpens. This makes novaculite sharpening stones ideal for general sharpening tasks. They are an exemplary choice for users that simply want a sharp knife without requiring anything special.

Japanese water stones

Japan’s geology offers a variety of natural stones with fine silica particles offering enough abrasiveness to be utilized as whetstones. Compared to the structure of novaculite, Japanese stones are much softer. They don’t take lubrication with oil lightly, so almost all are water stones. The soft structure of Japanese stones also make them require water to lubricate the surface.

Unlike novaculite, Japanese water stones have a great variety in grades. The naturally occurring stones can be from 500 to 10,000 grit, making them ideal for sharpening a knife from start to finish.

The different grades of Japanese water stones with varying coarseness are named as:

- Ara-to / Rough stone

- Naka-to / Medium stone

- Shiage-to / Finishing stone

In addition to these, there is also the nagura. This water stone, however, isn’t used for sharpening. It’s there to create the necessary slurry to sharpen a knife, which Shiage-to can’t produce due to high hardness.

Selling Japanese water stones is something to consider for knife stores with various Japanese cutlery. There isn’t a reason for Japanese knife enthusiasts to turn their back away to these unique, natural water stones. Nonetheless, it’s worth noting that they make one of the costliest whetstones.

Synthetic whetstones

Diamond stones

Diamond-coated whetstones are the coarsest of all. They cut aggressively and remove the most metal from a knife. As diamond is the hardest naturally occurring material, how it does this isn’t a mystery.

You can take a knife beyond dull and a diamond sharpening stone will sharpen it in just a few minutes. While this makes them very efficient in sharpening knives, it doesn’t always lead to the best outcomes.

The drawback to diamond stones is what makes them special in the first place – their coarseness. This can damage the edge rather than make it sharper, especially when used for sharpening a mildly wear-resistant blade. For this reason, they are best used before moving most knives to an extremely fine whetstone.

Oxide ceramic

Oxide ceramics cover a wide category of artificial metalloid and metallic elements. Naturally, these compounds are resistant to abrasion, high heat, and corrosion – sounds perfect for making whetstones.

Among ceramic oxides, aluminum oxide is the leading material for whetstones. Also known as India stones, aluminum oxide creates a balanced whetstone that carries the sharpness of knives to the top.

The sharpening stones made from aluminum oxide work best with blades that don’t have high resistance to losing material. Users can give a sharp edge to a knife made from soft steel with an aluminum oxide whetstone pretty easily – to the point it’s scary.

The abrasiveness of aluminum oxide is more like a polishing stone that enters the play following coarse sharpening stones. However, this doesn’t mean they lack ranging grit sizes. You can supply your audience with a variety of these sharpening stones that offer an excellent price-to-performance ratio.

Other than this, you may come across zirconium oxide whetstones though they aren’t as common. This is the same material as ceramic knives, and the whetstones have similar attributes to aluminum oxide but are much finer in structure.

Also known as zirconia, sharpening stones made from this ceramic oxide don’t cut as much, making them more suitable for polishing stones. They are available mostly in finer grits to polish and enhance the sharpness of the edge.

Carbide ceramic

Ceramic carbides are the coarser alternative to ceramic oxides. Depending on use, ceramic carbides, such as silicon carbide, can make better abrasives. They wear more material from the edge, but still a few steps down compared to diamond stones.

Silicon carbide is the highlight of ceramic carbides in whetstones – it’s hard and brittle. Although this is a bad trait to have in blades, it helps whetstones remove material. The added coarseness enables silicon carbide whetstones to wear down material from a knife’s edge faster. These whetstones create more slurry with every move, contributing to a quick sharpening. This, however, comes with a few downsides.

First, the whetstone wears down a lot faster. It means the user will get less out of a silicon carbide whetstone. Due to this, users find themselves needing to flatten their whetstones more often.

Silicon carbide whetstones might demand more from the users, but they sharpen knives faster. Depending on what the user intends to get from the sharpening stone, they can also be a somewhat more efficient tool for sharpening. For example, sharpening a knife that resists material loss more than average.

Buy Wholesale Sharpening Tools and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

What’s whetstone grit?

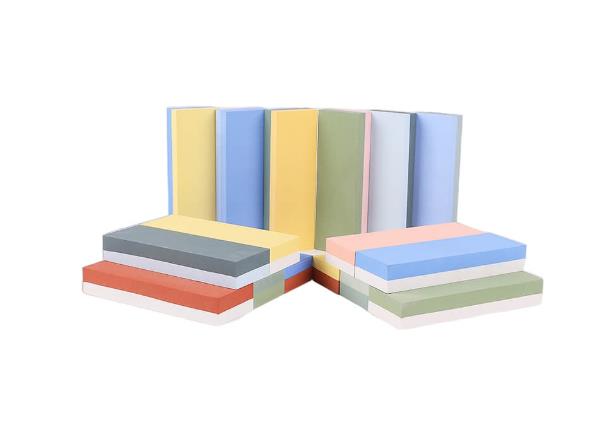

The grit size affects the whetstone’s characteristics relatively more than the material it is made from. Many whetstones come with two sides with different colors. These sharpening stones have two grit sizes in one. Usually, one side is for sharpening, and the other is for polishing, but it varies.

The grit sizes in whetstones can be anywhere from 100 to 30,000 or even higher. The lower the grit size, the more material the whetstone removes from the edge, and the faster it executes this.

We can classify whetstones based on grit size into three categories. These are as follows.

- Coarse stone: 100 to 1,000 grit

- Medium stone: 1,000 to 3,000 grit

- Finishing stone: 3,000 grit and higher

Coarse whetstones are usually in the range of 400 to 1,000 grit. This grit size is optimal for sharpening knives with high wear resistance and repairing chipped blades. For some knives, however, this can be too coarse. It can lead to microchips that don’t add to sharpness. These whetstones are more suitable for quick sharpening and fixing damaged edges.

Medium stones are ideal for general sharpening without the risk of microchips. Although sharpening a knife takes more time with medium stones, they benefit users with a trouble-free sharpening session.

Finishing stones (polishing stones) are higher than 3,000 grit. This grit size is reasonable for refining the cutting edge though it isn’t the best for sharpening a knife from scratch. They are best utilized after the blade gets some sharpening done with a coarse or medium stone. With this, the knife’s edge becomes already sharp, and the finishing stone turns it into a razor-sharp one.

We’ve covered whetstone grits in this in-depth article. Read to find the most appropriate whetstone grit sizes to sell in your knife store.

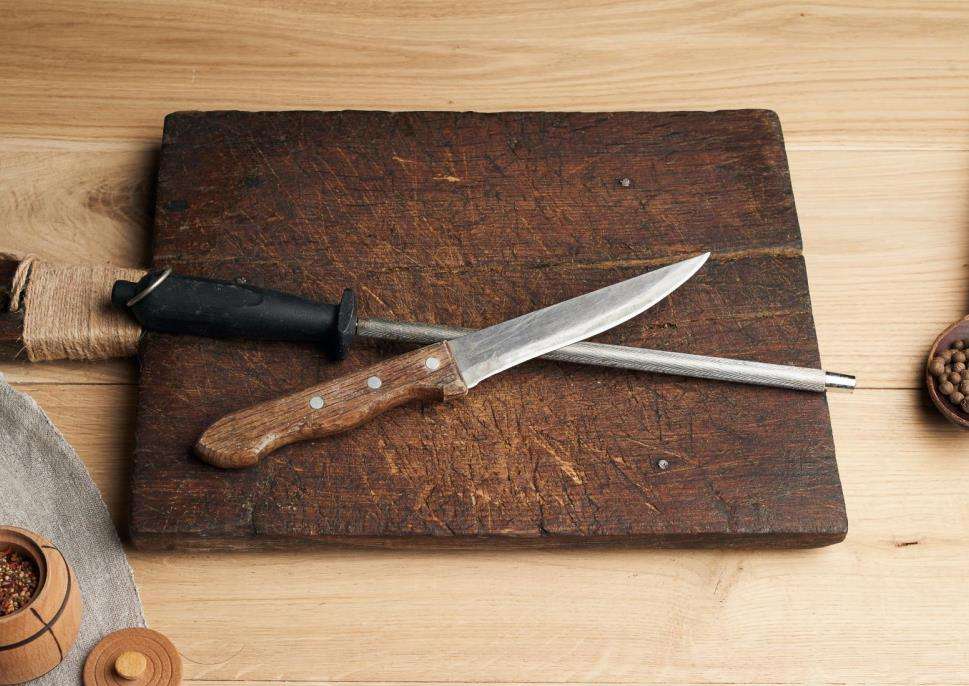

Whetstone vs. honing steel

Another effective alternative to making a knife sharp is honing steel. However, the use of honing steel and how it works is different from a whetstone.

A honing steel doesn’t always remove material from the edge, and it isn’t as consistent when it does so. Rubbing the knife’s edge against honing steel can shed material only when it’s harder and more wear resistant than the blade itself.

These sharpening tools mainly work by aligning the rugged sections of the edge, giving it a more or less temporary boost in sharpness. Many chefs utilize honing rods between meals to enhance the sharpness of their knives, but all knives require a whetstone eventually. The need for a whetstone is more prominent in knives made from hard steel.

How to choose a whetstone to sell

All these bring us to choosing the whetstone(s) to sell in your store. Like knives, you need to highlight products that appeal to your customers.

The best advice we can give is to look at the knives you have in stock and intend to sell in the future and pair the products you market with the appropriate whetstones. This is the best approach to finding the whetstones that can make a fitting product for your store.

For example, coarse stones made from silicon carbide are ideal for knives that pose challenges when sharpening. The knives that sharpen up easily shouldn’t have problems with medium stones made from aluminum oxide.

If you’re dabbling between different types of whetstones, we can help you make the right decision for your business. Browse our wholesale sharpening products.

Upon finding products that you think would be a good fit for your store, don’t hesitate to request a quote from us. LeeKnives is ready to be the only supplier you’ll ever need with a broad selection of wholesale goods.