Heat treatment for knives is the process of altering the blade’s properties to make it a better tool overall. The complete process can get very technical and hard to understand, even for a knife enthusiast.

In this article, we’ll cover what heat treatment is, why we heat treat knives, and the stages in the process in an easy-to-understand way without missing out on the important details.

Why knives need to be heat treated

Heat treatment is a necessary step in knifemaking to make the blade sufficiently hard yet be durable enough to endure the stress of robust work without a flinch.

Simply putting the steel in the forge and shaping the blade by hammering doesn’t give this outcome. Heat treatment requires precise temperatures, timing, and techniques special to the steel.

Knifemakers can still make a knife without heat treatment, but it wouldn’t cut as well. The steel used for forging the blade would be either too soft that can’t sustain an edge or hard and fragile. Heat treatment is a must for all knives, even those made from ceramic.

Heat treatment isn’t just for bringing the steel to its optimum hardness. Hardened steel can also be too brittle to make a knife. It also involves reducing the excess hardness that does more damage than good. For example, tempering hardened steel after quenching.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Science of heat treating

Heat treatment is a somewhat simple process that drastically changes the steel’s physical and chemical properties to our benefit. It’s a not-so-complicated process – heating and cooling cycles – but the science behind heat treatment can explain it for the better.

Steel isn’t a pure metal. It’s a mixture of iron and non-metal carbon with other chemical elements, like chromium and silicon. Covering multiple elements will require us to go over how they affect steel during heat treatment individually.

Examining high alloy steel under heat treatment will require us to go in-depth, which can get hard to understand. We’ll stick to iron and carbon mixture as it’s the simplest form of steel.

Crystal structure of iron

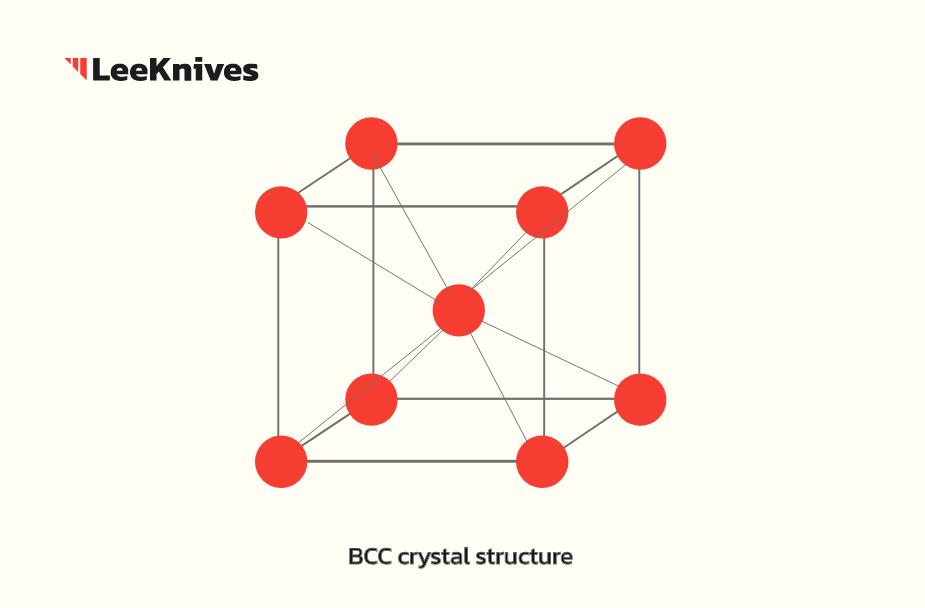

Pure iron forms a soft and stable metal known as ferrite, and it has a body-centered cubic (BCC) crystal structure. You can think of BCC as a cube with a carbon atom in each corner and one in the center. Each of these crystal structures deforms in one specific direction, meaning they want to move only towards that path.

This is known as the slip system, referring to the direction atoms slide past each other when deformation occurs.

When pure iron is heated and cools down, the crystals grow and form grains. Every grain has the same slip system, direction they want to deform, but the neighboring grains having the same is slim.

When you apply force to the metal, such as bending it, the grain can only slip in that orientation to deform. The force applied needs to be greater to push the grain next to it so that deformation occurs.

It’s like driving a car on the road with another parked in front of you – not impossible, but it won’t move anywhere easily. When the force is greater, the steel builds more internal stress. The internal stress can result in the steel shattering, cracking, or chipping easily under force. Enter carbon; things change exponentially.

Carbon’s effect on heat treating

As the present carbon increases, steel forms less ferrite and more cementite, an iron carbide alloy.

At elevated temperatures, around 1,000 C, cementite transitions to a different crystal structure known as austenite. However, this happens in steel with less than 2% carbon content.

Instead, cementite becomes more prevalent in the crystalline structure of the metal when there is more than 2% carbon. Cementite again begins to form, making the steel harder but more brittle. That’s why manufacturers rarely pass the 2% carbon threshold to prevent the steel from turning into a brittle material.

The primary difference between ferrite and austenite is the latter forms a face-centered cubic structure. This crystal structure is denser than BCC, but the heat opens spaces for carbon atoms to slip in.

This process of releasing carbon into the solution makes the metal stronger to deformation. Austenite is significantly stronger, less brittle, and prone to deformation than ferrite, increasing the metal’s toughness and hardness simultaneously.

Now, you should have an idea of what happens inside the steel during heat treatment though it takes some understanding of metallurgy.

Let’s take a look at the stages of heat treatment the steel undergoes when making a knife.

Normalizing

When the manufacturers forge the steel to make it ready for shipping, whether turning into a block or bar, the material develops internal stress, and the grain size becomes uneven.

Normalizing, as the name suggests, is essentially a reset button for the steel that relieves this internal stress and evens the grain size. The normalization increases the steel’s strength, making it ready for the further steps of knifemaking.

Process

The normalization process is very straightforward. The steel is heated evenly, usually in a tube, away from the direct fire until it reaches the transition temperature. Every steel has its transition temperature required for normalization, anywhere from 800 to 950 C, slightly above the critical austenite formation. This first step of normalizing is the recovery stage.

After the steel reaches this critical temperature above the recrystallization temperature but below the melting point, it’s held there for about one hour per 25mm thickness. This is where recrystallization occurs, leading to consistent grain size. Namely, this is the recrystallization stage of normalizing.

During this process, some steel forms pearlite, alternating layers of cementite and ferrite. When the carbide (and pearlite for some steel) is in the solution, the steel has an even grain size, accomplishing the goal of normalization.

The next is to leave the steel air-cool back to room temperature. This last step of normalization is the grain growth stage. The outcome is more ductile steel that’s easy to work with that won’t warp or crack.

Summarizing the normalization process

- Heat the steel just above its austenite formation temperature.

- Hold it for about one hour per 25mm thickness.

- Leave the steel air-cool to room temperature.

Once normalizing is complete, the steel is very ductile. It’s soft – not an ideal material to make a knife blade yet. The next step in heat treating is what brings out the hardness of the steel.

Quenching

Quenching is similar to normalizing but with one crucial difference. Instead of heating the steel and letting it cool in the air, it applies rapid cooling.

This rapid cooling promotes the martensite formation, the hard but brittle microstructure of carbon in iron that hardens steel. Quenching almost skips through the eutectoid point, the temperature austenite becomes unstable, which the carbon in the solution can escape.

Quenching can be performed through different media: air, water, oil, or brine. Here is the process of quenching steel and the differences between the quenching media used.

Process

Like the normalization process, the steel is heated above its recrystallization but below the melting temperature. Some steel requires a specific time window to stay at this temperature to soak the material. In other words, mix everything in the solution.

From there, the steel is rapidly cooled by either leaving it air-cool or submerging it in a tank filled with one of the following quenching media.

Quenching media

- Air: Air quenching is favored for its affordability as it doesn’t require anything but doesn’t work with every steel. Air quenching often cools the steel too slowly to affect its properties. Still, it’s a cost-effective way to quench steel for the few options that work with it, like D2 tool steel.

- Water: Water is a fast-working quenching media to cool steel. It offers a quick cooling back to room temperature. However, water quenching is prone to cracking most knife steel. So it doesn’t work with every steel, like air quenching. This quenching media works best with 1050 and W2 steel.

- Oil: Oil is the most common quenching media, as many steels require oil quenching. It doesn’t cool steel as fast as water does, but still much faster than air cooling. There are special quenching oils. One disadvantage of oil quenching is its flammability. It’s vital for knifemakers to quench the steel with proper safety equipment regardless of the media used.

- Saltwater: A water and salt (brine) mixture is the quickest way to cool steel. Saltwater achieves the fastest cooling because it doesn’t form air bubbles like regular water. The entire surface is covered with liquid, providing the fastest cooling. Again, this can be too fast for the steel and result in cracks.

While quenching improves hardness, it can make the steel more brittle. The more martensite there is, the more brittle the steel. Since brittleness isn’t a favorable trait in a knife, tempering is what comes after to reduce the hardness of martensite.

Tempering

Tempering is the heat treatment procedure that reduces brittleness caused by quench hardening. It balances the steel’s hardness and toughness by letting the carbon trapped in martensite escape and release the internal tension.

The result is softer but much stronger steel that resists deformation without cracking.

Process

The same as other heat treating methods, tempering starts with heating the steel. The difference this time is the temperature. Tempering is performed at much lower temperatures, around 125 to 400 C, depending on the knife steel.

Once the steel reaches its tempering temperature, it’s held for a specific time. Again, how long it stays depends on the steel. After this, the steel’s temperature is lowered until it cools at a set rate. For example, 250 C for one hour, 175 C for one hour, and 125 C for half an hour, then to room temperature.

Following tempering, the steel becomes tougher and can absorb shock without permanent damage as easily.

Summarizing tempering process

- Heat the steel to its tempering temperature.

- Hold the steel at this temperature for a set duration.

- Cool the steel at a predetermined rate to relieve internal stress and reduce excess hardness.

Tempering is essential for most steel after quenching. If not properly tempered, there’s a chance the steel needs to be normalized. Knifemakers must temper the steel carefully in a precise manner to prevent wasting the previous heat treatment steps.

After tempering, the blade is ready for grinding to perfect the shape and polish. In case the heat treatment processes are too complex, here’s a short rundown of the difference between differently heat-treated steel.

Difference between normalized, quenched, and tempered steel

Normalized steel is usually too soft for the characteristics of a knife we expect. It can bend easily and won’t hold a good cutting edge.

Quenched steel is incredibly hard but very brittle at the same time. Impacts to quenched steel before tempering can result in cracking as the internal stress built-up is too much.

Tempered steel has the best hardness and toughness ratio for the specific steel that’s heat treated. It’s sufficiently hard but also soft enough to absorb impact. As a knife material, the cutting edge won’t chip easily and sufficiently maintain its sharpness.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Annealing

There is also annealing, which is a heat treatment method that doesn’t apply to knives as much. The purpose of annealing is to prepare the steel for cold working, such as machining, grinding, or cutting. This heat treatment method brings the steel or any other metal to its softest form, ensuring it doesn’t deform under the above courses.

Annealing follows a similar process to tempering but requires much higher temperatures and a very slow cooling rate. Naturally, it takes longer to anneal steel than temper.

Final words

Heat treatment is almost always necessary for knives to have a durable blade that stays sharp for a satisfying duration. It’s a long and precise process. Any steel with proper heat treatment can make a blade that cuts reasonably well.

LeeKnives is a wholesale knife manufacturer that utilizes a large selection of knife steels to forge knives. We can supply your knife store with a broad range of products, from Japanese specialty to general-purpose knives to sets.

We also provide our clients with other services to help them grow. LeeKnives can help you manufacture unique, custom knives down to the smallest detail you pictured and ship them in the packaging you desire.

Click here to request a quote with the services that interest you, order quantity, and contact information. We will get back to you in no more than two business days.