The grind of a knife is an essential aspect of the functionality and performance of a blade, affecting its cutting power, durability, and level of maintenance. As you explore the world of knives for your business, understanding the different types of grinds and their unique characteristics will help you choose the most suitable blade for your specific needs.

The grind of a knife refers to the way the blade’s edge is shaped through a sharpening process, which involves removing material from the blade to create the desired edge profile. Various types of knife grinds offer unique benefits for different cutting tasks, so it’s crucial for you to familiarize yourself with common grind styles and their applications.

Throughout this article, you will gain a deeper understanding of knife grinds and their variations, equipping you with the knowledge to make well-informed decisions when selecting your next knife to sell. We will examine the most common types of grinds, such as flat, hollow, and convex grinds, along with their advantages and disadvantages in different scenarios. Armed with this information, you’ll be better prepared to choose the perfect blade for your needs.

How does knife grinds impact the performance of a knife

When it comes to knives, the grind is a critical aspect that influences its performance and functionality. Knife grinds refer to the shape and angle of the blade’s edge, which significantly impacts its cutting ability, strength, and sharpness.

To get a better understanding of how the grind of your blade determines its performance, let’s delve into some key factors.

First, the sharpness of a knife is directly related to the grind. A well-designed grind can provide a sharp edge that facilitates easy, precise, and efficient cutting. However, not all grinds are created equal; some allow for razor-sharp edges, while others prioritize durability over sharpness.

Toughness

Secondly, the grind can affect the strength of the knife’s edge. A blade with a thick grind will be stronger and more resistant to chipping, but it may not offer the same level of sharpness as a thinner grind. On the other hand, a blade with a thin grind may be incredibly sharp but more prone to damage during heavy-duty tasks.

Food separation

Moreover, the grind also plays a role in food release. Some grinds feature a flat or near-flat surface that allows for smoother separation of sliced food from the blade. Others, like those with prominent bevels, provide additional air pockets, which help prevent food from sticking to the knife.

Finally, it’s important to consider the maintenance of your knife. Certain grinds might require more frequent sharpening and may be extremely difficult to sharpen like a convex edge. If the edge wears out quickly your customers will surely have a hard time bringing the edge back to life.

Understanding how knife grinds impact the performance of your knife is extremely important- Both for the investment of your store and for your customers. Experienced customers will even seek out specific grind types that match their expectations.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

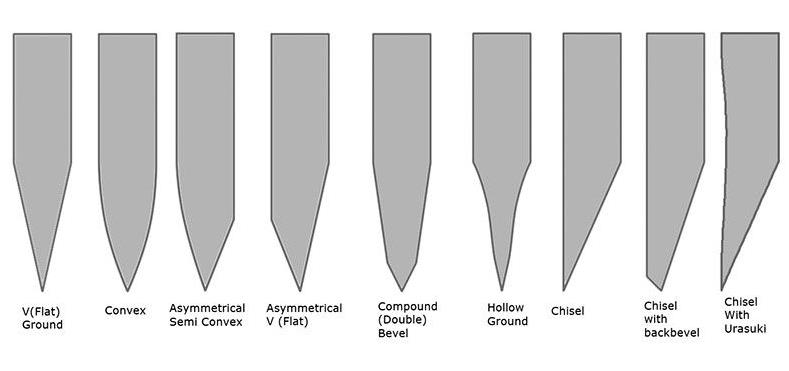

Types of knife grind

Flat grind

A flat grind is a simple and versatile type of grind where the blade tapers evenly from the spine to the edge. It’s great for slicing, making it an ideal choice for kitchen knives and general-purpose tools.

There are different variations of flat grinds, depending on the angle of the bevels. These include:

- Full Flat Grind: The entire blade tapers from the spine to the edge.

- High Flat Grind: The bevel starts higher up the blade, creating a thin and sharp edge.

- Low Flat Grind: The bevel starts lower down the blade, resulting in a more durable edge.

Convex grind

A convex grind has a curved bevel, which creates a strong and durable edge that’s excellent for chopping and splitting tasks. This type of grind is often found on axes and other heavy-duty tools. To create a convex grind, the material is removed from the blade in a slightly arched shape, allowing the edge to maintain its strength without compromising on sharpness. It’s very hard for home cooks to re-sharpen convex grind blades. The smooth, curved edge requires maximum precision even for specific machines to achieve. This is the reason why convex grind knives are hard to come by.

Hollow grind

The hollow grind features a concave bevel, resulting in an extremely sharp edge that’s perfect for precision tasks. This grind is particularly popular among straight razors, where an ultra-sharp edge is desired. However, the thinness of the edge may make it susceptible to wearing out quickly, which is why it’s not commonly used for heavy-duty tasks.

Chisel grind

In a chisel grind, only one side of the blade is beveled, while the other side remains flat. This results in an asymmetrical edge that’s very sharp and easy to maintain. Chisel grinds are often found on traditional Japanese knives, woodworking tools, and some outdoor knives. It’s important to note that this grind may not always provide the most balanced cutting experience, particularly for tasks requiring control and precision.

V grind

A V grind is named for the shape it creates, wherein the blade tapers in a V shape from the spine to the cutting edge. This type of grind is common on pocket knives and sport knives, providing a good balance between sharpness and durability. V grinds can be further subdivided into:

- Scandi Grind: Features a wide and flat bevel, offering impressive edge stability.

- Saber Grind: It has a narrower bevel, resulting in a thinner edge that’s great for slicing.

Serrated knife edge

So far, all the knife grind types discussed are designed for straight-edge knives. However, there is a unique category of knives that doesn’t quite fit into these conventional grinds – the serrated edge knives. These knives have their own special grind, characterized by a series of sharp, scalloped teeth along the blade’s edge.

Serrated edge knives are particularly well-suited for tasks that require sawing or slicing through tough materials, such as bread, tomatoes, or rope. The serrations on the blade’s edge create points of contact that grip and cut through the material effectively, making them indispensable tools in the kitchen and beyond. Serrated edge knives bring a different level of versatility to the world of cutlery, catering to specific cutting needs with their unique grind.

Each of these knife grinds has its unique qualities, making them suitable for specific applications. Choosing the right grind for your needs will depend largely on the tasks you plan to perform and personal preferences.

Factors influencing grind performance

When evaluating a knife’s grind, several factors contribute to its performance. As a user, it’s essential for you to understand these factors, as it will help you make an informed decision when selecting the right knife grind for your needs.

Edge angle: The cutting edge is the sharp part of the blade that comes into contact with the material being cut. Different grinds create varying cutting edge angles. A smaller angle creates a sharper edge, offering better precision, while a higher angle provides additional durability and edge retention at the expense of cutting performance.

Thickness: The thickness of the blade directly affects its cutting ability. Thinner knives can easily glide through materials with less resistance, making them ideal for tasks requiring precision and intricate cuts. However, thicker knives are more robust and provide additional strength for heavier tasks. The grind must strike a balance between thickness and cutting ability to ensure optimal performance.

Friction: The knife’s grind impacts the amount of friction generated when cutting through materials. Grinds that have larger surface areas in contact with the material, such as flat grinds, create more friction, which can lead to difficulties while cutting. Conversely, grinds with less surface area, like hollow grinds, minimize friction and allow for smoother cuts.

Knife grind and blade maintenance

Proper sharpening depends on the type of grind your knife has, as well as your intended use for the knife. For example, a flat grind is versatile and easy to sharpen, making it suitable for a variety of tasks. On the other hand, a hollow grind is sharper and ideal for slicing but may require more frequent maintenance. Whichever grind your knife has, it is essential to maintain the correct bevel angle when sharpening to ensure optimal performance.

Regular maintenance is crucial for extending the life of your knife and keeping it in optimal condition. This involves cleaning, sharpening, and storing your knife correctly. After using your knife, clean it with warm soapy water, ensuring to remove any residue or moisture that may cause corrosion. Dry your knife thoroughly before storing it in a safe, dry location, away from moisture and other potential hazards.

In addition to cleaning, regular sharpening is necessary to maintain the knife’s cutting edge. The frequency of sharpening depends on the type of grind and usage. More frequent use will require more frequent sharpening. You can use a sharpening stone, honing rod, or a specialized sharpening tool to maintain your knife’s edge.

Understanding knife grind is crucial

Choosing the right knife grind is a big part of knife manufacturing. As a seller, you always need to consider the quality, durability, and cutting performance of your knife before making the final decision. Each grind type has its advantages and drawbacks, hope this guide has helped you to select the one that aligns with your visions the most.

If you are interested in manufacturing a knife with specific designs, why not contact us? We have dedicated services to help you achieve optimal knife designs. Including various types of knife grinds. Shoot us a message, request a quote, and we’ll get back to you asap!