Pocket knives are versatile tools that have evolved from simple cutting instruments to multifunctional devices. Pursued and carried by people all over the world. It’s always the right time to invest in the pocket knife market. Whether you are an outdoor enthusiast, a craftsman, a wholesaler, or just someone who appreciates the utility of a good knife, understanding the anatomy of a pocket knife is the first step in getting into the pocket knife world. Every part of the pocket knife has a specific function, working together to provide strength, durability, and ease of use.

The basic structure of a pocket knife includes a blade and a handle. Sounds simple enough, but both parts also house multiple components. With so many terminologies thrown around the pocket knife community, you’ll want to be familiar with each unique part of a pocket knife that will decide the utility and manufacturing price of the knife. From blade to locking mechanisms, this article will cover all you need to know. Without further ado, let’s get started!

History and evolution of pocket knives

The evolution of pocket knives parallels the historical timeline. In ancient times, Romans crafted basic folding knives, setting the foundation. Early models featured simple pivots without locking mechanisms. The 17th century saw advancements in steel, giving rise to diverse but simpler pocket knives. The 18th-century Industrial Revolution brought mass production, leading to varied styles. The 19th and 20th centuries marked modernization with multi-blades and locking mechanisms.

Today, contemporary pocket knives blend classic design with cutting-edge technology, utilizing high-grade materials for enhanced durability. This evolution showcases how different parts, from basic pivots to advanced locking mechanisms, have adapted over centuries.

Anatomy of a pocket knife

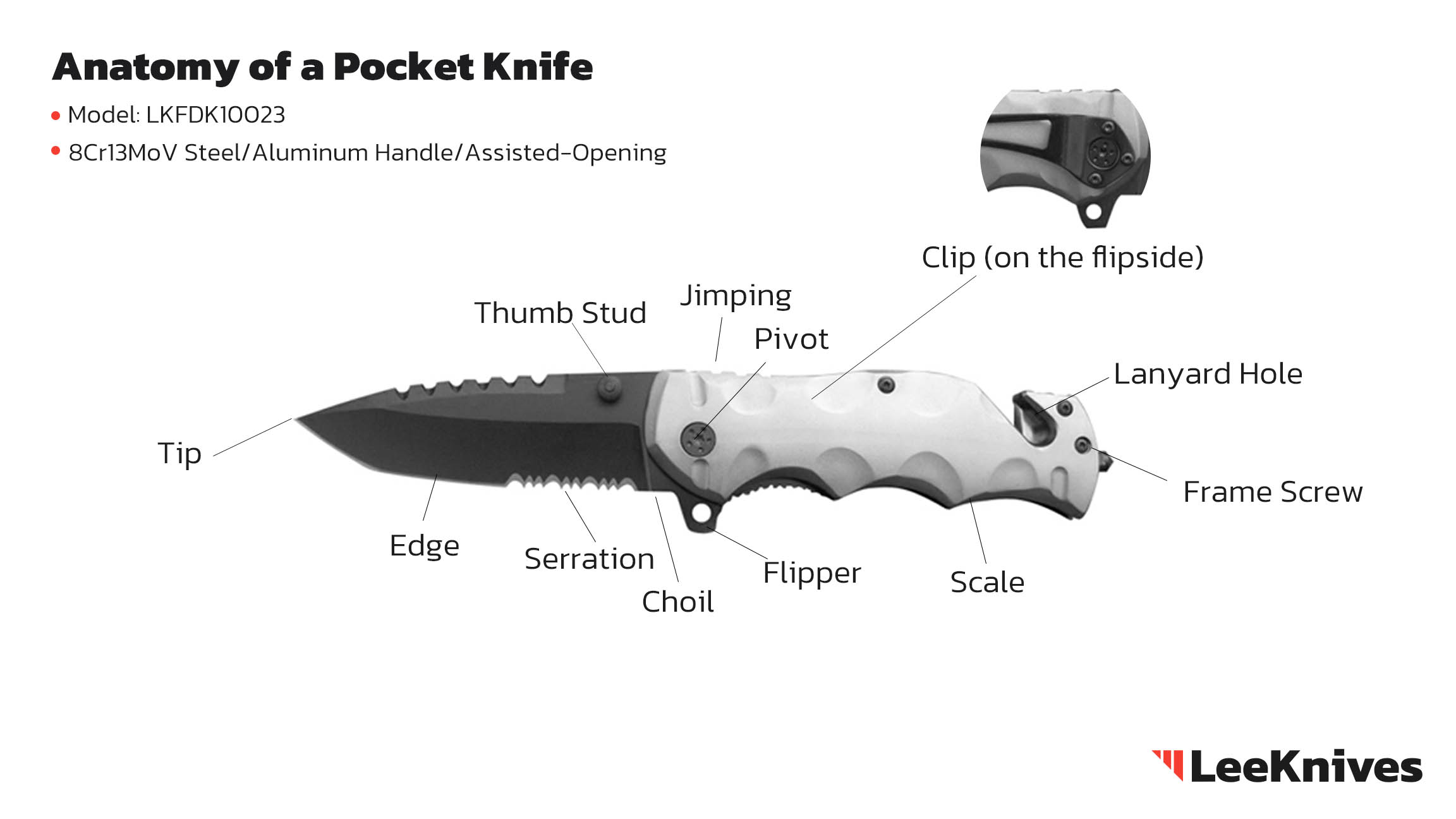

Here is an image depicting the structure of a pocket knife. If you’ve read our kitchen knife anatomy article, you might recognize certain terms, such as the tip and the edge of the pocket knife, as well as the handle. However, unlike kitchen knives, the versatility in the design of a pocket knife allows for numerous optional, smaller components that may not always be essential for its composition.

In the following sections, we will delve into a detailed explanation of the general components of a pocket knife that shares with a kitchen knife. Reserve specific parts of the blade or handle in later sections.

Tip

The tip of a pocket knife refers to the pointed end of the blade, often crucial for precision tasks. It comes in various shapes, such as drop point or tanto, influencing its functionality. The tip enhances the knife’s versatility, aiding in delicate maneuvers and providing options for different cutting styles.

Bevel

The bevel of a pocket knife is the sloping surface that forms the blade’s cutting edge. It plays a crucial role in determining the knife’s sharpness and cutting performance. Bevel angles vary, affecting durability and slicing ability. A well-crafted bevel contributes to the knife’s overall effectiveness in various cutting applications.

Learn more about knife bevel:

Edge

The edge of a pocket knife refers to the sharpened portion of the blade responsible for cutting. It is a vital element influencing the knife’s cutting efficiency and performance. Different edges, like plain, serrated, or combination, cater to diverse cutting needs, enhancing the knife’s adaptability for various tasks.

Serration

Serration on a pocket knife refers to notched or tooth-like patterns along a section of the blade’s edge. It enhances cutting performance for specific tasks like sawing through tough materials. Serrated edges are valuable for their ability to grip and tear, complementing the knife’s versatility in various cutting scenarios.

Tang

The tang of a pocket knife is the extension of the blade into the handle, providing structural support and stability. It comes in various styles, such as full, partial, or hidden, influencing the knife’s strength. A robust tang enhances durability, making it a crucial factor in evaluating a pocket knife’s overall construction.

Learn more about knife tang:

Bolster

The bolster of a pocket knife is a thickened area where the blade meets the handle, adding strength and balance. While common in fixed-blade knives, many folding knives omit a bolster to streamline opening and locking mechanisms. Bolsters, when present, contribute to durability and can serve as an aesthetic element in knife design.

Learn more about knife bolster:

Spine

The spine of a pocket knife is the top, unsharpened edge of the blade opposite the cutting edge. It provides structural integrity to the blade and supports various functionalities. The spine’s thickness can influence the knife’s strength, and it may include features like jimping for improved grip during use.

Blade steel

The blade steel of a pocket knife refers to the material used in crafting the blade. Common types include stainless steel and high-carbon steel, each offering distinct properties like corrosion resistance, sharpness retention, and ease of sharpening. The choice of blade steel significantly impacts the knife’s overall performance and longevity.

Learn more about pocket knife steel:

Buy Wholesale Pocket Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Blade design and features

When considering a pocket knife, the design elements and features of the blade determine its functionality for various tasks. Be it for everyday carry or specific applications, a well-constructed blade can make all the difference.

Blade shapes

The blade shape of a pocket knife plays a pivotal role in its functionality, with diverse designs catering to specific tasks.

The Drop Point, characterized by a rounded spine descending towards the tip, offers a robust point for controlled tasks. The Clip Point, featuring a crescent drop on the spine, excels in precision. Inspired by Japanese design, the Tanto shape boasts a high point and flat grind for piercing strength. The Wharncliffe shape, with a straight edge tapering to a point, excels in slicing. Sheepsfoot knives, with a straight edge and curved, unsharpened spine, are ideal for efficient chopping. Each shape enhances the knife’s versatility.

Learn more about pocket knife blade shapes:

Choil

The choil of a pocket knife serves the purpose of making the sharpening process easier. Its design allows users to access and sharpen the entire length of the blade, contributing to the maintenance and longevity of the knife’s cutting edge.

Handle components

The handle is a critical component of a pocket knife, affecting both its aesthetic and functional qualities. It’s where you interact with the knife, so its construction dictates the tool’s comfort and durability.

Pivots

The pivot of a pocket knife is the central point around which the blade rotates during opening and closing. It consists of a screw mechanism that connects the blade to the handle. A well-maintained pivot ensures smooth and reliable knife operation, influencing overall functionality and user experience.

Jimping

Jimping on a pocket knife refers to small notches or grooves, typically found on the spine or choil of the blade. It enhances grip and control, providing a textured surface for the thumb or fingers. Jimping is strategically placed to improve handling during various cutting tasks, promoting user precision and safety.

Clip

The clip of a pocket knife is a metal attachment, often shaped like a clip, affixed to the handle. It facilitates convenient pocket carry by securing the knife to the edge of a pocket. The clip ensures accessibility while preventing accidental loss, making it a practical feature for everyday carry enthusiasts.

Lanyard hole

The lanyard hole on a pocket knife is a small opening in the handle, designed for attaching a lanyard or cord. It serves practical purposes, preventing loss by securing the knife to the user’s wrist or gear. The lanyard hole adds a functional and convenient element to pocket knives for everyday carry.

Scale

The scale of a pocket knife refers to one of the two handle panels, typically made of materials like wood, G-10, or metal. It provides a comfortable grip and contributes to the knife’s overall aesthetic. Scales can be textured or contoured, enhancing ergonomics and making the knife more versatile for various applications.

Opening/locking mechanisms

Pocket knives vary in their opening and locking mechanisms, resulting in diverse components and designs. The anatomy of different opening and locking mechanisms differs accordingly. For example, the thumb stud in the above image represents an assisted-opening opener.

Opening mechanisms

The opening mechanism of a pocket knife refers to how the blade is deployed for use. Manual opening requires the user to physically unfold the blade, typically using a thumb stud, nail nick, or other manual means.

Automatic knives, also known as switchblades, employ a spring-loaded mechanism activated by a button or switch, allowing rapid, one-handed deployment.

Assisted-opening knives combine manual and spring-assisted features, using a thumb stud or flipper to initiate the blade’s movement, with a spring then completing the deployment.

Dual-action knives, often associated with automatics, offer both manual and automatic deployment options. Users can either manually open the blade or use the automatic mechanism, providing flexibility in how the knife is accessed based on preference or legal considerations in different jurisdictions.

Learn more about opening mechanisms:

Locking mechanisms

The locking mechanism of a pocket knife is integral for securing the blade in a fixed position during use, ensuring safety and stability. It prevents accidental closures that could lead to injuries. The opener, on the other hand, facilitates the unlocking process, allowing the user to close the blade when needed.

Different locking mechanisms offer varying levels of strength, ease of use, and safety features, contributing to the overall functionality and reliability of a pocket knife.

Common pocket knife lock types include liner locks, frame locks, and lockback mechanisms. Liner locks feature a metal liner that moves into position behind the blade, securing it. Frame locks involve a portion of the handle moving to lock the blade. Lockbacks have a pivoting latch that engages the blade’s base.

Learn more about knife locks:

Buy Wholesale Pocket Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Selecting the right pocket knife for your business

When choosing a pocket knife for your business needs or wholesale purchase, understanding the components and the quality of a pocket knife is essential. Look for blades made of high-quality steel which ensures strength and maintains a sharp edge longer. Consider steel with a higher amount of chromium content for its rust resistance.

Your choice should depend on what your target customers want. If precision cutting is key, look for a knife with a sharp point and a fine edge. For rugged use, a thicker blade and a robust construction might be more appropriate.

When choosing the right knife, prioritize both aesthetics and practical considerations in anatomy and terminology. If you want to have a say in every little part of the pocket knife you want to sell, working with a manufacturer that has the resources and ability is paramount. LeeKnives is one of the few commercial handmade knife manufacturers that allow detailed OEM production to suit your needs. Contact us today to get a quote for your knife!