Customizing Kitchen Knives Makes You Unique: LeeKnives Offering ODM Solution

LeeKnives is a wholesale knife original design manufacturer (ODM). We take on your ideas and create products for sale out of thin air.

What Is ODM? What Is an ODM Kitchen Knife Manufacturer?

ODM is also called Original Design Manufacturer. It’s a process where we create unique, high-quality products tailored specifically for your brand.

Instead of buying off-the-shelf knives, you can have knives that reflect your vision and meet your customers’ needs.

An ODM kitchen knife manufacturer designs and produces knives for your brand, allowing you to sell them under your own label. Think of it as a one-stop solution where creativity meets efficiency.

At LeeKnives, we specialize in turning your ideas into reality with our expertise in both design and manufacturing.

How Is an ODM Knife Built?

Step 1

Let us know your ideas for a new knife, including the usage scenarios, functional requirements, design preferences, etc.

Step 2

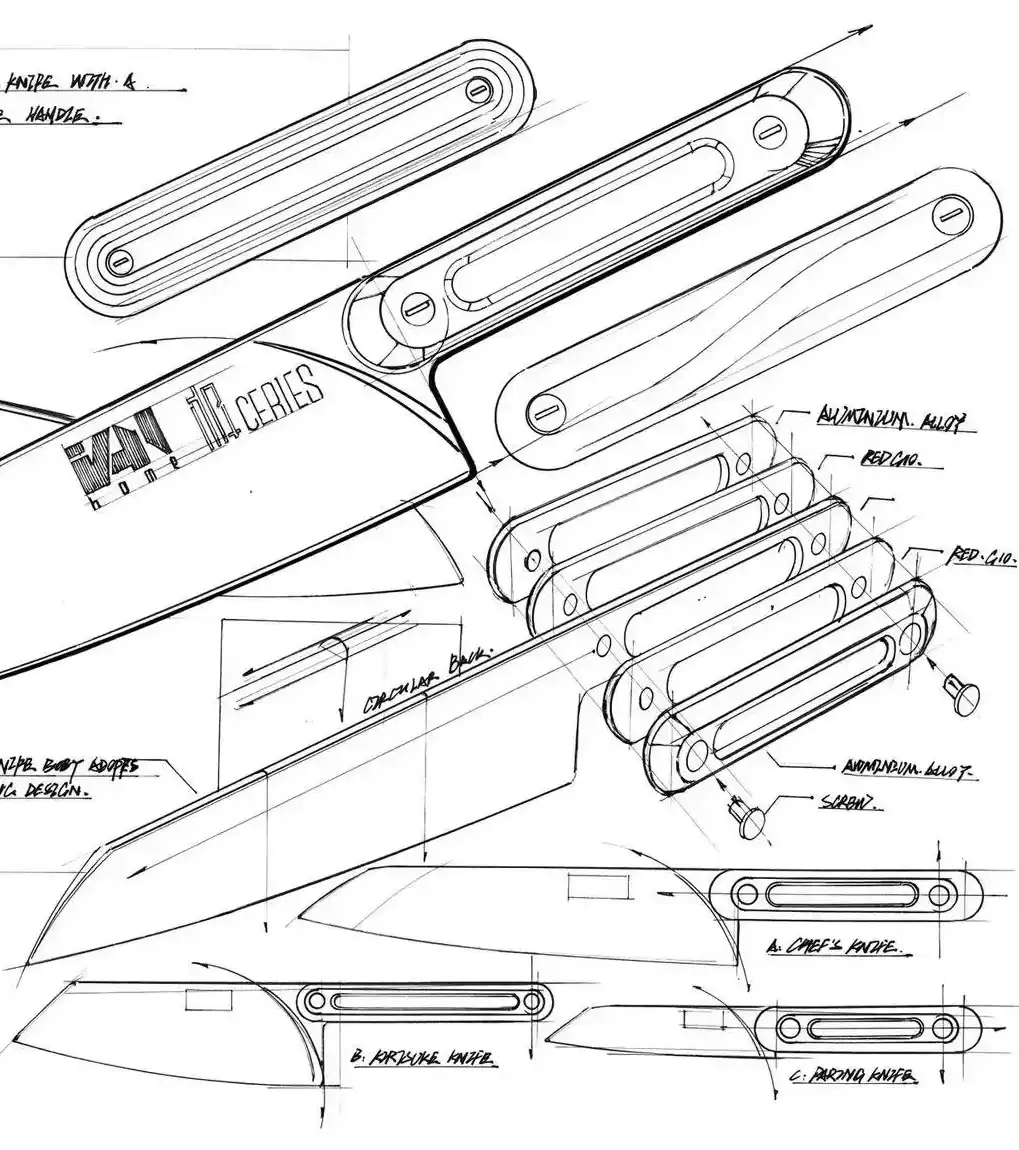

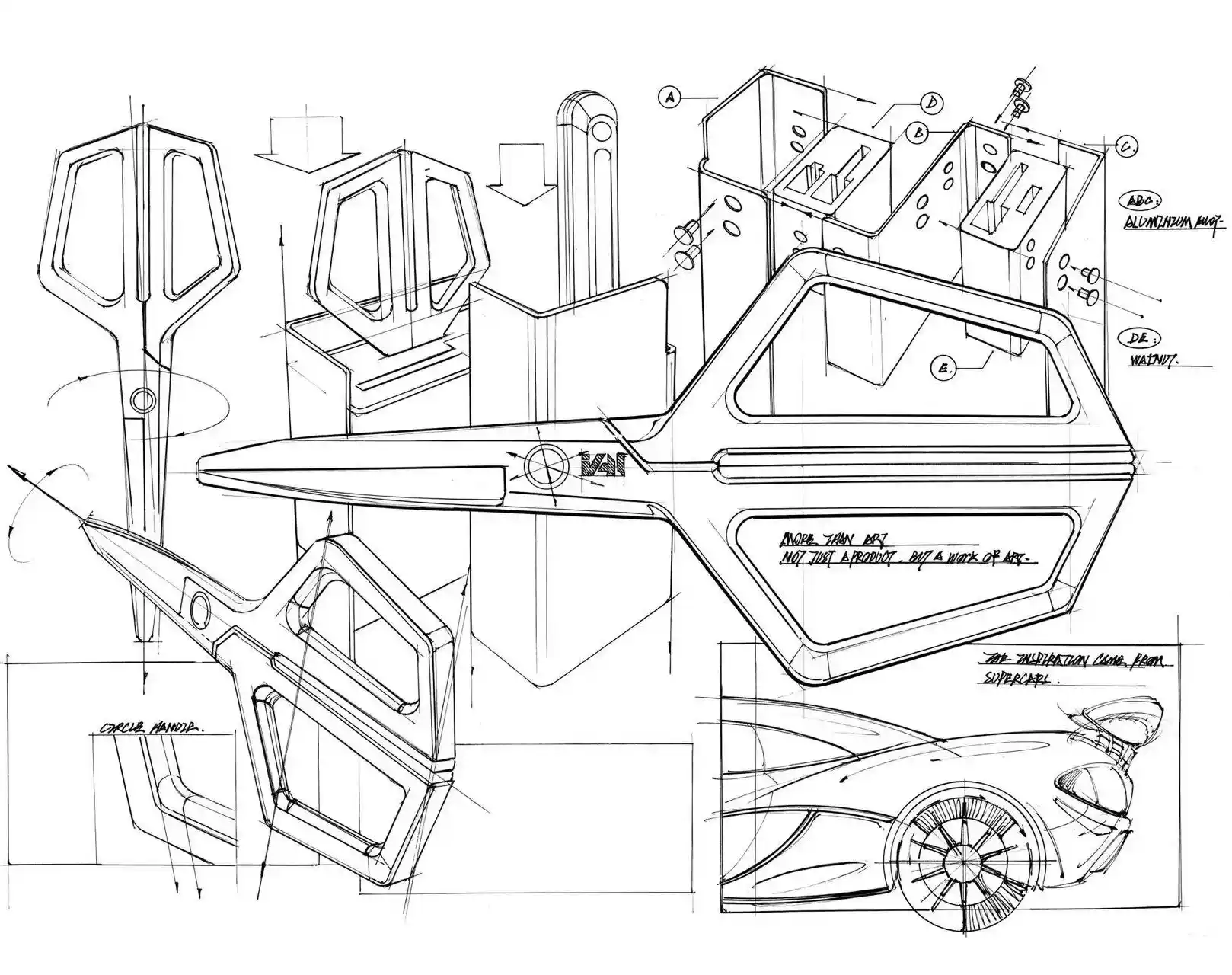

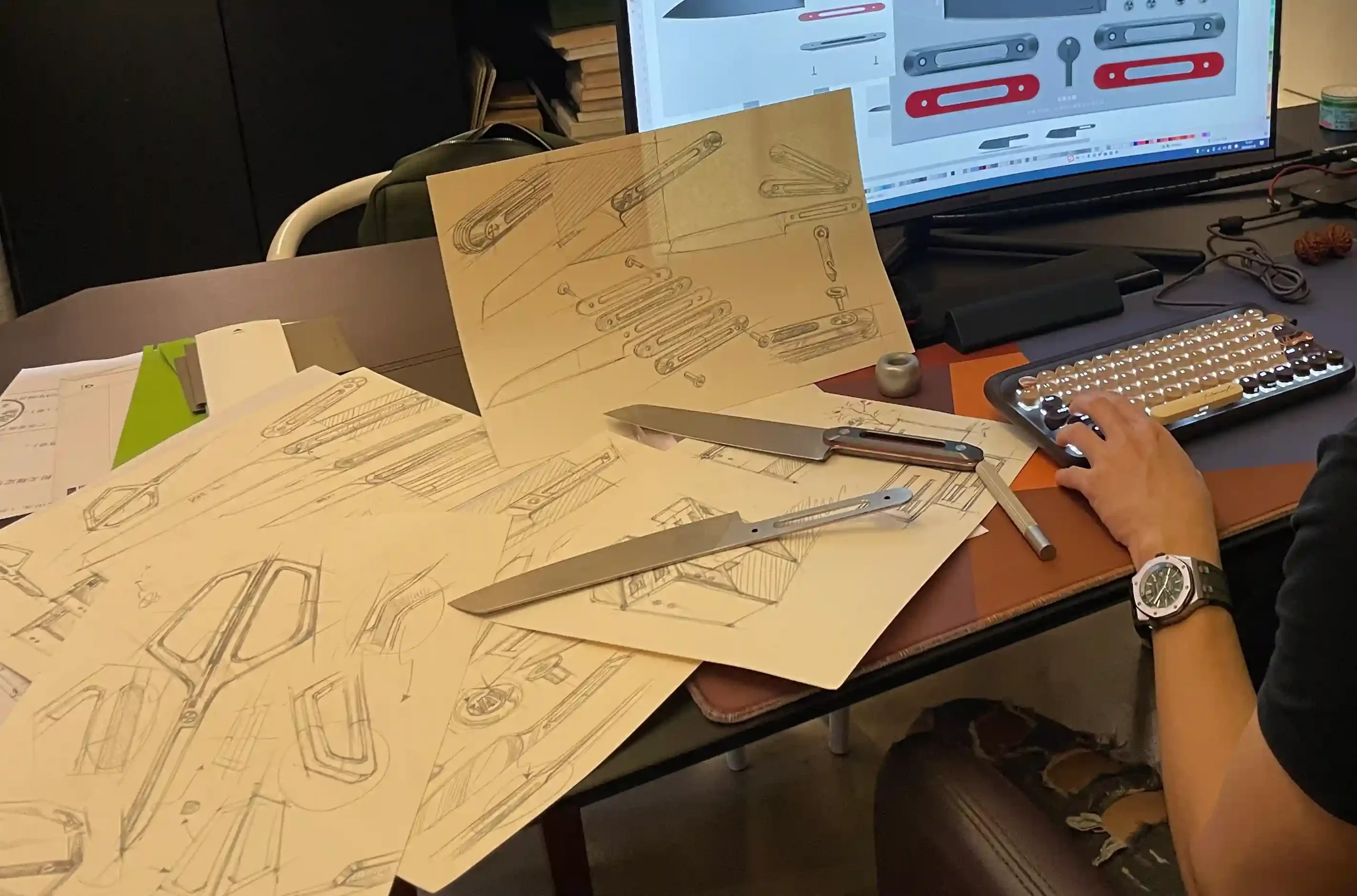

Then, according to the communication results, we make preliminary design sketches, including blade shape, length, and handle style.

Step 3

Discuss and revise the design sketches until both parties agree on a detailed design plan.

Step 4

After confirmation, we draw 3D mock-ups for prototypes and run usability as well as feasibility trials. Then we’ll send the mock-up to you for detailed discussion.

Step 5

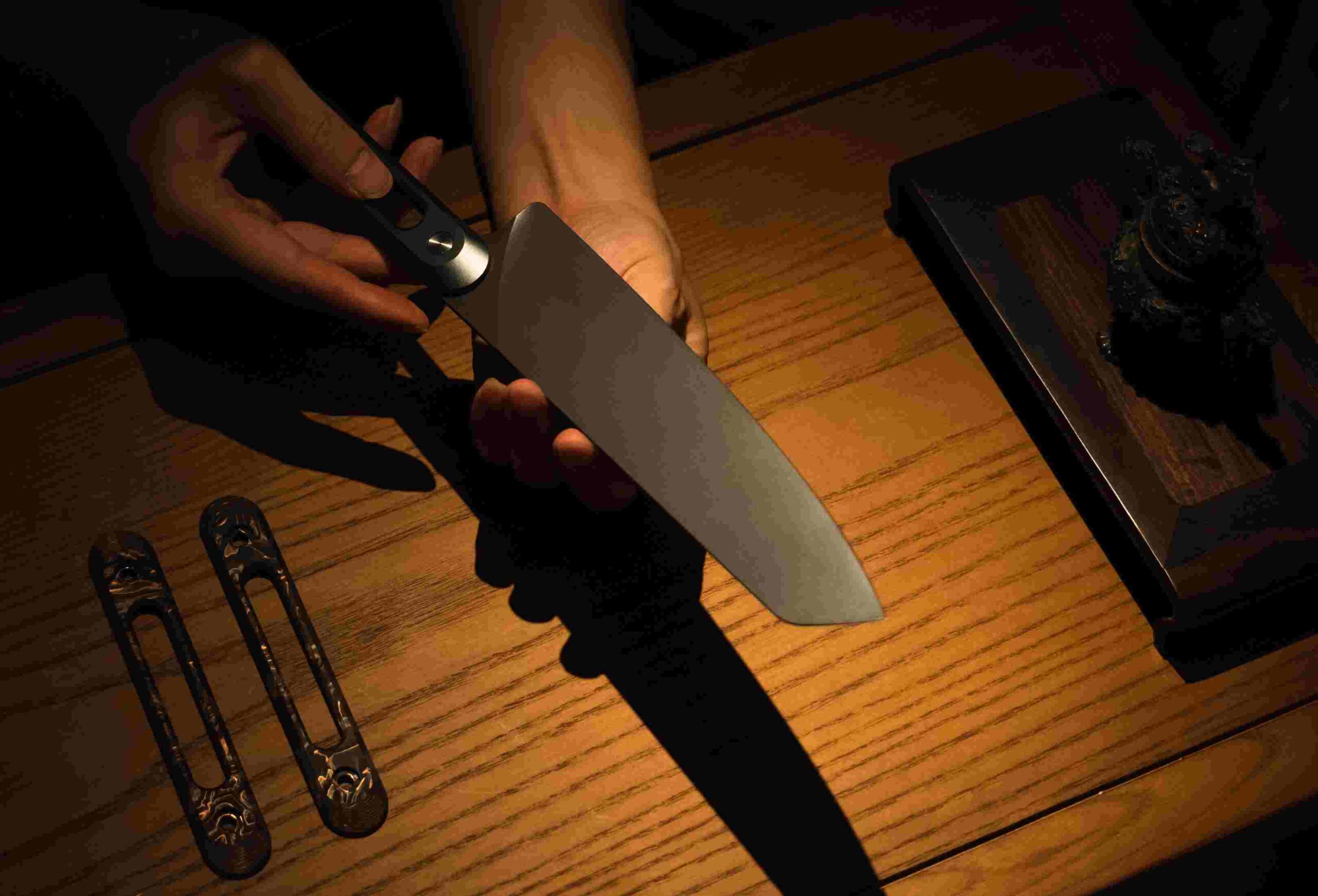

We manufacture a test product and send it to you for further inspection.

Step 6

We make sure your ideas and expectations were heard before mass production. If the test product is approved by both parties, we will start the line.

Design Team

.webp)

Concept Development

Our designers will work closely with you to develop initial concepts, providing sketches and 3D renderings that bring your ideas to life.

Material Selection

We offer expert guidance on selecting the best materials for your knives, ensuring durability, sharpness, and aesthetic appeal.

Ergonomic Design

Our team specializes in ergonomic handle design, ensuring that your knives are comfortable to use and reduce hand fatigue.

Brand Integration

We understand the importance of your brand identity. Our designers will seamlessly integrate your brand’s logo and design elements into the final product.

1993

Company Established

12000+

Factory Area

500+

Employed Staff

200+

Advanced Machines

Blade Material

Handle Material

Technology

-scaled.webp)

01 Shaping

Steel is pressed into the desired blade shape using a shape-cutting machine.

03 Cryogenic Treatment

It enhances blade performance by increasing hardness and wear resistance through the transformation of retained austenite to martensite. It also reduces internal stresses, improving dimensional stability and durability.

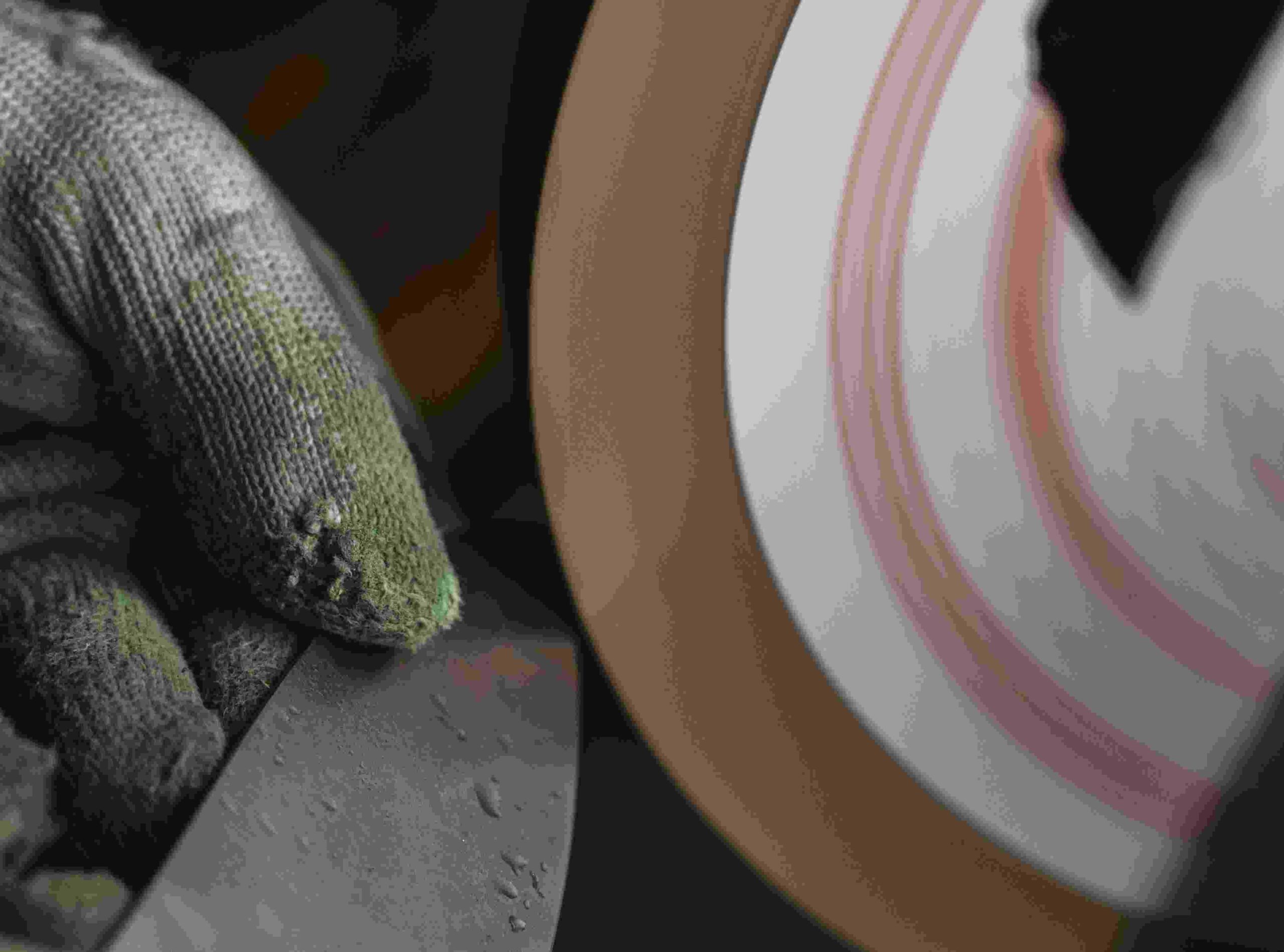

05 Sanding

The sanding stage is vital for refining the blade’s shape. Eliminating any sharp edges adjacent to the handle, smoothing the knife’s spine, and enhancing the blade’s edge sharpness. To accomplish this, an automated sanding belt is employed.

02 Heat Treatment

Precisely control temperatures when heat-treating blades to increase hardness and durability.

04 Wet Grinding

Its primary objectives include cooling and lubricating the treated surface, reducing heat buildup. Wet grinding not only cleanses the surface by removing abrasives and debris but also enhances later grinding steps such as sanding.

06 Installing Handle

Using traditional and modern techniques, the handle is securely fitted to the blade to ensure a comfortable and firm grip.

07 Blade Edging

Creating a precise edge for the blade and customizing the edge shape for different applications to ensure cutting efficiency.

09 Packaging

The final step before our knives are ready to go. Customized packaging designs are employed to cater to the distinct requirements of each customer.

08 Inspection

Followed by ISO standard, a comprehensive test will take place to examine the initial sharpness and edge retention of the knife.

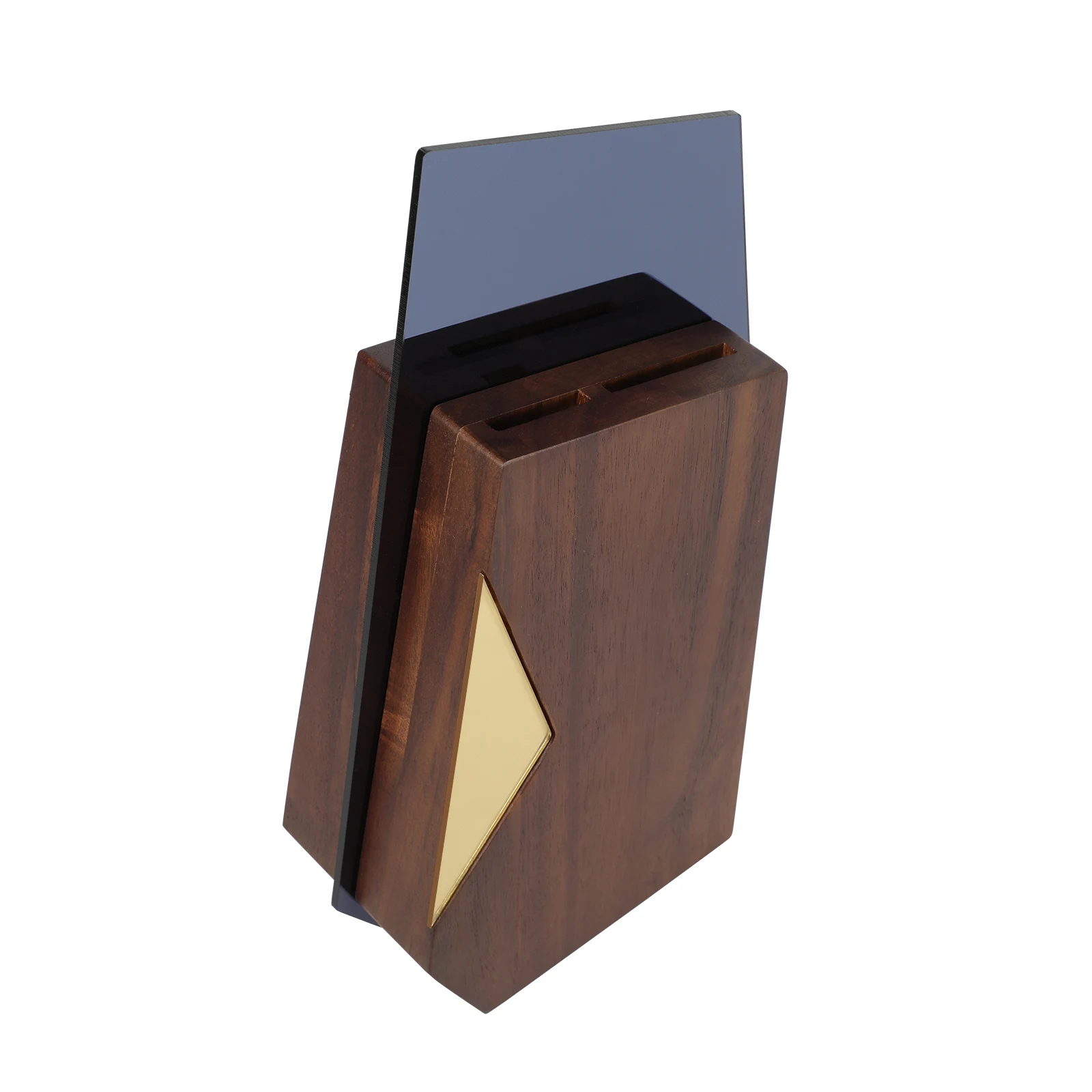

New Released Products

LeeKnives recently released products feature award-winning designs and superior materials, ensuring exceptional performance and durability. From professional chefs to home cooks, these knives are expected to cause a trend in the kitchen knife industry and become representative pieces. Explore our collection and elevate your kitchen knife business with LeeKnives’ commitment to excellence.

ZDF-905 Powder Steel Aluminium Alloy Kitchen Knife Set LKKSE10034

ZDF-905 Powder Steel Aluminium Alloy Kitchen Knife Set LKKSE10035

Multi-Functional Magnetic Knife Block LKKST20020

Multi-Functional Knife Block LKKST20021

The Best ODM Knife Manufacturer You’ve Been Looking For

Innovative Design: Our designers stay ahead of kitchen trends, ensuring your knives are not only functional but also stylish.

Customization: We offer complete customization, from blade shape and handle design to logo placement.

Quick Turnaround: Our efficient processes mean faster lead times without compromising quality.

Quality Assurance: Every knife undergoes rigorous testing to ensure it meets the highest standards of sharpness, durability, and performance.

Tips for ODM Corporation

Frequently Asked Questions

Why should I make ODM products?

Customers appreciate fresh products or even fresh interpretations of one product. By making ODM knives you are in the chance of making new consumption phenomenons. At the end of the day, who doesn’t want to be hit by dopamine day in and day out?

How do you charge for ODM services?

The cost varies depending on material expenses, labor expenses, and various factors that may affect the cost per unit. You can always consult with our support and get a reasonable quote.

How long does it take to develop an ODM product?

The lead time is associated with the complexity of your product. We may exchange ideas and make adoptions before final decisions. But once the sample is approved, it will take roughly 45 to 60 days for mass production. Contact our support to know how long your products may take.

What’s the difference between OEM and ODM?

ODM is also known as the private label service. It allows customization AFTER a product is made. While OEM means the products will be made BASED on a client’s customizations.

Experienced Knife Makers Ready to Make Your Ideas Come to Life

Got an idea for the next star product? Contact us and we’ll help you produce & distribute them.