Texas isn’t just known for its vast landscapes and cowboy culture—it’s also a hotbed for some of America’s most talented custom knife makers. From tactical blades built for durability to artistic pieces that blend tradition with innovation, Texas knife artisans bring a unique blend of skill, heritage, and creativity to their craft. Below, we highlight the top custom knife makers in Texas, their specialties, and what makes their work stand out.

Traditional & Heritage Knife Makers

Harvey Dean

Harvey Dean’s introduction to knifemaking began in his teens, sparked by a love for outdoor adventures and a curiosity for metalwork. He honed foundational skills through self-study and mentorship from local blacksmiths, later formalizing his training in metallurgy and blade forging. By his late 20s, he transitioned from a part-time hobbyist to a dedicated craftsman, drawing inspiration from Texas’ ranching and wilderness culture.

Based in West Texas, Harvey operates a small, family-run workshop focused on custom and semi-custom knives. He works full-time as a knifemaker, balancing traditional hand-forging with modern precision tools. An avid outdoorsman, he frequently tests his designs in local terrains—from desert trails to ranchlands—refining them based on real-world use.

| Specialties | Rugged Utility Blades: Specializes in durable fixed blades tailored for outdoor work, hunting, and ranching, with thick spines and reinforced tangs for heavy use. Forged Steel Expertise: Known for hand-forged blades using high-carbon steels and Damascus patterns, emphasizing edge retention and toughness. Ergonomic Practicality: Designs handles with textured materials (stabilized mesquite, micarta) for secure grip in wet or muddy conditions, prioritizing comfort during long use. |

| Notable Achievements | “Best Utility Fixed Blade” “People’s Choice” awards for his ranch-style knives Member of the Knifemakers’ Guild and holds a Journeyman Smith certification from the American Bladesmith Society (ABS) |

| Unique Selling Point (USP) | Texas-Trail Tested Hand-Forged Heritage Customized for Purpose |

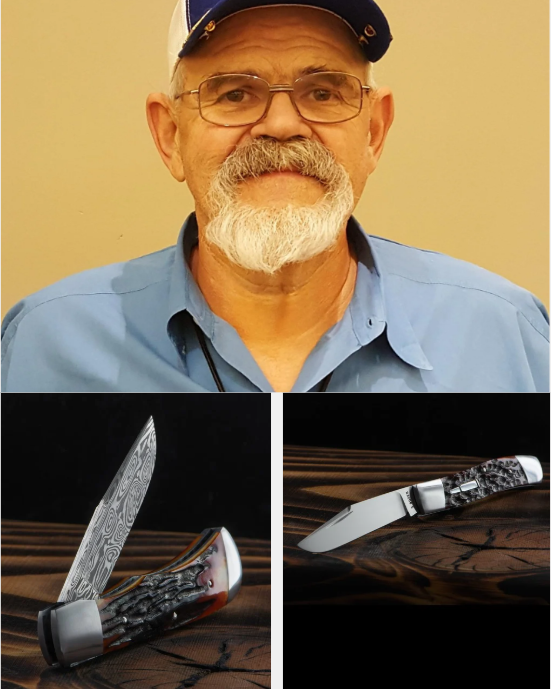

Bill Ruple

Born in Charlotte, Texas in 1951, Bill Ruple began as a peanut farmer. He learned knifemaking from friend and bladesmith Pat “Ticho” West in 1988—with a promise to pass the craft forward. When federal farm programs shifted in 2002, making peanut farming unprofitable, he turned to full-time knifemaking, focusing on traditional slip-joint pocket knives. His work, celebrated for meticulous craftsmanship and faithful classic replicas, gained popularity among collectors, dealers, and notable figures like Oscar winners and Grammy artists.

| Specialties | Master of traditional pocket knives: slip-joint designs, multi-blade folders (e.g., trappers). Uses traditional materials like stag, jigged bone, mother of pearl, mammoth ivory and amber wood, paired with precise handcrafting. |

| Notable Achievements | Served on the Texas Knifemakers’ Association board. Earned the ABS President’s Award for teaching slip-joint craftsmanship. Won the 2019 BLADE Show Aldo & Edda Lorenzi Award. |

| Unique Selling Point (USP) | Heritage reimagined Blend of tradition and quality |

Tom Overeynder

Tom Overeynder started knifemaking in 1977, self-taught through metalworking experiments and a focus on classic designs. He honed skills in hand-forging and precision grinding, drawing inspiration from vintage utility knives. Today, based in the U.S., he runs a small workshop crafting custom knives full-time, blending traditional handcraft with modern materials while testing designs in outdoor settings to refine usability.

| Specialties | Focus on collector-grade folders; occasionally makes bowies, chute knives, etc. Uses premium steels (CTS-XHP, PSF-27, Damascus, etc.) and 416 stainless steel frames. Employs stable handle materials: mother of pearl, jigged bone, mammoth/hippo ivory, wood, micarta, and carbon fiber. |

| Notable Achievements | 1986: First Beretta Award for Outstanding Achievement (with Bob Lum) at Knifemaker’s Guild Show. Multiple “Best Folder,” “Best Multi-blade,” and “Best Art Knife” wins at Guild Shows, Blade Show, and Lone Star Expo (2002–2025). 2019: “Buster” Award for best body of work at Art Knife Invitational (AKI). Member: Knifemaker’s Guild (1983–2016, voting), Texas Knifemakers Association (charter), CKCA, and AKI (inducted 2016). |

| Unique Selling Point (USP) | Collector-grade craftsmanship Award-winning excellence Heritage & quality |

Bob Merz

Bob Merz’s knifemaking journey began in the 1980s, sparked by a passion for precision and functional design. With a background in tool and die making, he honed metalworking skills that translated seamlessly to bladecraft. After decades refining his craft part-time, he now operates Merz Knives full-time from his workshop, focusing on custom creations while balancing technical precision with artistic detail.

| Specialties | custom folding knives and fixed blades, Uses premium steels (e.g., CPM-S30V, M390) durable handle materials (G-10, stabilized wood, carbon fiber). Emphasizes tight tolerances, smooth action, and ergonomic grips tailored to user comfort. |

| Notable Achievements | Recognized at national knife shows with awards for “Best Tactical Folder” and “Excellence in Craftsmanship.” A longstanding member of the Knifemakers’ Guild, known for consistent quality in custom bladework. |

| Unique Selling Point (USP) | Precision-engineered knives Premium performance User-focused design |

Stan Buzek

Stan Buzek brings decades of metalworking expertise to knifemaking, honing his craft through hands-on experience in precision fabrication. He launched his knifemaking journey focusing on custom designs, blending technical skill with artistic vision. Today, he operates a dedicated workshop, crafting full-time and prioritizing personalized client collaborations to refine each piece.

| Specialties | Custom folding knives and fixed blades, with a focus on intricate detail and balanced functionality. Uses premium materials: high-performance steels (e.g., Damascus, CPM-S35VN) and exotic handle materials. Emphasizes hand-finished craftsmanship, from blade grinds to seamless component fitment. |

| Notable Achievements | “Best Custom Folder” and “Excellence in Craftsmanship.” |

| Unique Selling Point (USP) | Bespoke precision Premium material mastery Handcrafted excellence |

Pete Truncali

Pete Truncali’s knifemaking journey began with self-taught metalworking, where he developed foundational skills in forging, grinding, and finishing through hands-on experimentation. Over 20 years of practice, he refined his craft, focusing on mastering blade geometry, material compatibility, and functional design.

Today, he operates a full-time, dedicated workshop, prioritizing custom knife creation tailored to client specifications. His process involves close collaboration with users—from concept to completion—to ensure each piece aligns with practical needs and aesthetic preferences. With a focus on precision and durability, he continues to hone his techniques to balance utility and artisanal quality in every knife.

| Specialties | Custom folding/fixed blades with precision craftsmanship. |

| Notable Achievements | Recognized at regional shows for craftsmanship and design excellence. |

| Unique Selling Point (USP) | Bespoke knives blending functional precision with artisanal quality for users/collectors. |

Andy Isaacks-Tech-meets-craft

Blending traditional craftsmanship with practical innovation, Andy Isaacks honors knifemaking’s heritage while integrating modern precision. His roots in Boy Scouts and outdoor adventures fuel a focus on durable, utility-driven blades—crafted with hands-on skill honed through guild workshops and mentorship.

Drawing on his CAD/CAM background, he refines designs digitally before bringing them to life with artisanal care, upholding traditions via memberships in the American Bladesmith Society and Texas Knifemakers Guild. This fusion of time-tested craft and technical precision keeps his work rooted in tradition, elevated by modern rigor.

| Specialties | Blends CAD design expertise with hands-on craftsmanship to create quality handmade knives. Focus on functional designs, rooted in outdoor utility and technical precision. |

| Notable Achievements | Texas Knifemakers Guild (2016; Lonestar Knifemaker 2017; Ranger Knifemaker 2024) American Bladesmith Society (2017) Voting Member of Knifemakers Guild (2024) |

| Unique Selling Point (USP) | Tech-meets-craft |

Tactical & Outdoor Knife Makers

For Texas’ harsh landscapes (deserts, forests) and demanding users (law enforcement, survivalists), these makers build blades that endure.

Todd Begg

He started making knives at the age of 12 in 1983. After graduating from high school, he joined the army and became a member of the NBC reconnaissance team. He later obtained a machinist’s degree at San Juan College in Farmington, New Mexico. He also worked as an aerospace machinist for about five years before giving it up in 2003 to focus on knife – making.

Now based in Dallas, Texas, he crafts 150 high-quality handmade knives yearly, focusing on precision in form and function. Known for blending sci-fi and classic designs, he pioneered use of the IKBS bearing system and invented the 2012 interbolton framelock technology. His knives use premium steel for strength and toughness. He also serves on local knifemakers’ union boards and industry roles.

| Specialties | Tactical knives, folding knives, survival blades |

Notable Achievements | President of the Knifemakers’ Guild Member of the American Bladesmith Society 2014 “Best Tactical Folder” for Sun Tzu Kwaiken |

Unique Selling Point (USP) | Intricate blade/handle designs Blending sci-fi and classic design elements for unique, versatile aesthetics. |

David Broadwell

David Broadwell’s fascination with knives dates back to his childhood. Inspired by tales of slaying dragons with his father’s masonic dress sword, the passion for edged tools smoldered within him. In his mid – twenties, in 1981, he took a broken file and crafted his first knife. Recognizing his calling, he left his machinist job in 1989 to become a full – time knifemaker. He has also been involved in children’s ministries at his church since his oldest daughter was young and supports local charities.

| Specialties | Blending Damascus steel/exotic materials (mammoth ivory) for artistic-tactical appeal. Engineering durable, field-ready blades optimized for survival and hunting. Precision craftsmanship: symmetric grinds, clean lines, and client-tailored custom details. |

| Notable Achievements | Best Tactical Folding Knife award Best Tactical Fixed Blade award in past BLADE Shows |

| Unique Selling Point (USP) | Artistic design + real-world functionality—gallery-worthy knives that perform in the field. “Texas-tested” toughness for outdoor and survival use in harsh terrains. Versatile options: tactical blades, folders, and custom creations (e.g., stone handles). |

Gary Chalette

Gary Chalette’s knifemaking journey began with a childhood fascination for tools and craftsmanship. He honed mechanical skills early, working with metal and wood in his teens. After formal training in precision machining, he transitioned to custom knifemaking full-time in the 1990s, drawing inspiration from Texas’ rugged outdoor heritage and functional tool design.

| Specialties | Utility-first design: Ergonomic handles & tough steels Rugged tactical/outdoor focus: Sturdy fixed blades/folders with clean lines, reinforced locks, and practical features Precision details:Hand-finished edges, tight component fit, and subtle touches |

| Notable Achievements | “Best Utility Knife” “Outstanding Tactical Design” |

| Unique Selling Point (USP) | Texas-proven durability Crafted for practicality Premium materials |

Artistic & Collectible Knife Makers

Ron Appleton

Ron Appleton, son of the renowned Ray Appleton, has long been involved in the knife – making world. As a long – standing member of the prestigious Art Knife Invitational (AKI), he has spent years perfecting his craft. His journey in knife – making has seen him create some of the most unique knives globally, often collaborating or influenced by his father’s work.

| Specialties | Creates highly unique knives Blends different high – quality materials |

| Notable Achievements | Long – term member of the esteemed Art Knife Invitational (AKI) |

| Unique Selling Point (USP) | Unique craftsmanship: distinct designs high – end construction innovative locking mechanisms |

Johnny Stout

Johnny Stout’s knifemaking journey began in 1983, marking over 40 years of dedicated craftsmanship. Self-taught and driven by a passion for precision, he honed his skills through decades of hands-on experimentation, evolving from early designs to mastering complex folding knife mechanics. Today, he operates Stout Knives full-time, focusing on custom creations and educational workshops, with a reputation as a leading figure in the custom knife community.

| Specialties | Damascus steel masterpieces—“Stout Damascus” flows like water, with handles of exotic materials that tell stories. |

| Notable Achievements | Member of the American Bladesmith Society and Texas Knifemakers Guild. Invited as a guest maker at prestigious events like the Las Vegas Art Knife Invitational. “Best Folder” at the Arkansas Knife Show (2021) |

| Unique Selling Point (USP) | Decades of mastery premium materials artisanal detail |

Competitive & Niche Innovation Makers

J. Alex Ruiz

J. Alex Ruiz developed a passion for metalwork early, honing skills through self-directed learning and mentorship in custom knifemaking. With years of hands-on practice, he now runs a dedicated workshop, focusing on bespoke knife creation. His journey blends technical curiosity with a commitment to refining traditional and modern techniques.

| Specialties | Crafts custom fixed and folding knives Uses high-grade steels unique handle materials |

| Notable Achievements | Recognized in regional knife shows for craftsmanship excellence. |

| Unique Selling Point (USP) | Custom knives balancing ergonomic utility with meticulous craftsmanship |

Allen Elishewitz

Born in Texas, Allen Elishewitz lived in various Asian locales like Indonesia, Taiwan, Singapore, and Thailand during his youth. His early exposure to diverse cultures, combined with over 30 years of martial arts training (Okinawan te, Thai boxing, etc.) and his service as a recon marine, provided a rich backdrop. While in college, he began part-time knifemaking, transitioning to full-time after graduation in 1988. Since then, he’s continuously refined his craft and is an American Knifemakers Guild member since 1994, once the youngest in the guild.

| Specialties | tactical and utility knives crafts both fixed and folding blades |

| Notable Achievements | “Best Utility Knife” at 1992 Lone Star Knife Show in Dallas. “Beretta Award” at 1995 guild show. “Knifemaker of the Year” by Fighting Knife Magazine in 1996. “Best High – Tech Knife” at 2001 SICAC in Paris. |

| Unique Selling Point (USP) | Fusion of martial, military expertise with artisanal skills |

What Makes Texas Custom Knife Makers Unique?

Texas custom knife makers thrive on a mix of heritage and innovation. Rooted in the state’s rugged, self-reliant culture, many artisans draw inspiration from Western history—crafting blades that honor cowboy traditions, hunting legacy, and frontier resilience. At the same time, they embrace modern techniques: from high-performance steel alloys (like S35VN and 1095) to advanced forging methods that enhance durability and sharpness.

Collaboration and community also set Texas apart. Many makers, like J. Alex Ruiz, teach workshops across the state, passing down skills to the next generation. Organizations like the Texas Knifemakers’ Guild (TKG) foster connection, ensuring the craft stays vibrant and evolving.

Buyer’s Guide: How to Choose a Texas Custom Knife Maker

When investing in a custom knife from Texas, consider these key factors:

- Purpose: Are you looking for a hunting knife, tactical tool, or collectible art piece? Makers like Harvey Dean excel at utility blades, while Ron Appleton focuses on mechanical art.

- Materials: Check for high-quality steel (Damascus, CPM-S30V) and handle materials (stabilized wood, G-10, or rare finds like mammoth ivory). Texas makers often source local or ethically sourced materials.

- Certifications: Look for credentials like ABS Master Smith (American Bladesmith Society) or membership in prestigious groups like AKI, which signal expertise.

- Turnaround Time: Custom knives take time—from 3 weeks (Todd Begg) to several months for intricate pieces. Discuss timelines upfront!

Final Thoughts

Texas’ custom knife makers prove great knives thrive on passion, heritage, and precision—whether hand-forged Bowie knives, tactical field blades, or artful collectibles. But for businesses turning knife concepts into reality—for kitchens, outdoors, or everyday carry—blending that craftsmanship with scalability matters most.

That’s where LeeKnives comes in. As a trusted OEM/ODM manufacturer, we bridge artisanal quality and production efficiency. Inspired by Texas’ tactical ruggedness, heritage designs, or innovative spirit? We offer end-to-end support: custom design, private labeling, and reliable supply chains—all without sacrificing standout quality.

Ready to turn your knife idea into an enthusiast favorite, just like these Texas makers? Reach out today. Let’s craft something great—together.