The steel used for forging a blade gives the end product the exact attributes. Utilizing layered steel to make a knife is a common practice for knifemakers to give their products the best qualities of two or more options.

While steel is the best material for making knives, not all are equal. Most perform greatly in one aspect but fall short in another. For example, hard knife steel holds an edge incredibly well but isn’t as durable.

It’s the other way around for tough steel. They are resilient to damage and absorb impact without a hush but don’t cut for as long. Constructing the blade in a planned way using layered steel supplies it with attributes that otherwise would be impossible with single steel.

There isn’t an only way to forge a blade like this. Find out the two most common practices for making knives with layered steel in this article.

What is a layered steel knife?

The layered steel is essentially two or more steel put together. Following this technique, knife blades can have hundreds of individual steel pieces.

Blacksmiths accomplish this by welding together different steel and putting them in the forge. Knifemakers heat everything around 2,000°F to make them reach their austenitic phase. Since not all steel has the same temperature requirements, they can be generous with the heat.

A layered steel knife carries multiple properties in a single blade. However, mixing random steel doesn’t lead to appropriate outcomes. For example, making layered steel by mixing very hard and soft steel randomly can result in a knife that won’t cut evenly.

Knifemakers must have enough experience and utilize compatible materials to forge a blade with layered steel.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Forging techniques that create layered steel blade

There are two primary ways to forge a layered steel blade. These are Damascus pattern welding and San Mai.

One is a forging technique that glimpses at the past. The other is a Japanese method to create a knife that stays sharp for long but is also durable enough to absorb impacts.

Damascus pattern welding

Damascus steel is a highly-sought knife material initially created using wootz steel. The methods of producing this unique steel with stunning patterns have been long lost since the 19th century.

While the earliest Damascus steel is now a thing of the past, the demand for it has always continued. The closest pathway to recreating the product of the past is through pattern welding.

This, however, is not a new forging method knifemakers came up with after trying to bring back the appearance of Damascus steel swords. Knifemakers would melt and pound multiple steel blocks until they bonded as far back as the late-1300s.

Pattern welding process

As simple as it sounds, pattern welding refers to forging multiple steel billets together in the forge. The captivating patterns don’t appear directly from this, though.

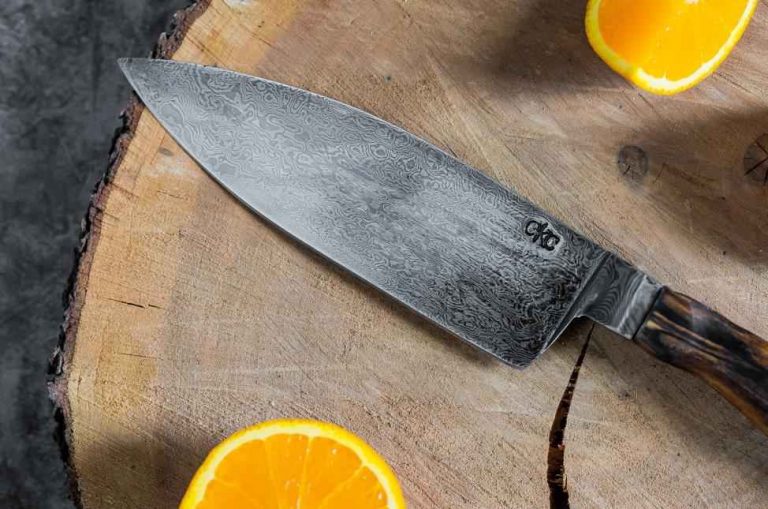

After the knifemaker makes the steel ready and builds the blade, it undergoes acid etching. The blade is dipped in acid, revealing where every steel bonded in different patterns. Since these look identical to the patterns found on Damascus daggers and swords, it’s how Damascus steel is produced today.

There are multiple Damascus patterns knifemakers can achieve. How the steel is put together and bonded results in various pattern types. Learn more about Damascus patterns and how they are made.

What does pattern welding do?

Knifemakers utilize the pattern welding method to give their blades a natural aesthetic appearance. The patterns occur randomly.

As a result, every Damascus blade is different. Having something unique to them is what drives most people into Damascus knives, whether for kitchen use or EDC.

Pattern welding doesn’t just create visually attractive knife blades. It also changes the steel properties. This forging method can produce a robust and sharp knife blade.

However, it depends on the steel used. As mentioned, it can also create the opposite outcome. That’s why knifemakers need to utilize compatible steel comparable to one another.

Pros of selling Damascus knives

- Visually striking: The patterns on Damascus knife blades are unique to every knife. This can give a sense of ownership to the user and prize it above other knives in their collection.

- Performance: Pattern welded knives have more than just one type of steel. Therefore, they have various steel properties in a single blade. Users can expect a better degree of performance than an average knife.

Cons of selling Damascus knives

- High costs: The multi-step forging process requires intensive labor and expert blacksmithing. Not every knifemaker can create a decent pattern welded blade, let alone a good quality. These drive the cost of producing pattern welded knives.

- Long lead times: Producing pattern welded steel can take anywhere from tens of hours to weeks. This means a custom order with your specs will have longer waiting times. Nonetheless, we ensure quick turnaround times at LeeKnives.

San Mai

San Mai is an ancient Japanese blade constructing technique. It dates back to 1,300s and uses hard and soft steel.

In the past, knives made following San Mai had tamahagane at the core, one of the earliest high carbon steels. This steel was praised for its ability to hold a fine edge for long. However, it wasn’t as durable and could chip easily following aggressive cutting.

Since this was the best available steel at the time, Japanese blacksmithing invented San Mai, which translates to three flat things. In this case, three flat steel – the translation is very literal, and here is why.

San Mai blade making process

The San Mai technique is still widely used for Japanese kitchen knives. These knives have hard steel in the core and softer steel on both sides.

During the forging process, the hard steel is jacketed with tough steel. After hammering continuously to bind the steel, everything is the same as making any other knife.

Creating the edge by grinding the steel reveals the hard steel at the core as it gets thinner and thinner. The result is a blade that keeps its sharp edge significantly longer than an average knife. Yet, durable enough to absorb impacts that otherwise would be impossible to bear for the steel in the middle.

What does San Mai blade construction do?

The purpose of San Mai is to create a blade that’s exceptionally sharp and durable at the same time. This blade making method protects the hard steel at the core, ensuring it doesn’t chip as easily.

Overall, the San Mai layered steel brings the best of hard and soft steel in a precise manner.

Users can only tell if their blade is made following the San Mai technique unless they get to use it for some time or the knife goes acid etching. Similar to how Damascus steel is dipped in acid, a similar process reveals squiggly lines where the soft steel covers the hard steel.

Unlike Damascus blades, San Mai doesn’t have as much visual appeal to buyers. Nonetheless, knife enthusiasts still tend to favor them over regular knives.

Pros of selling San Mai knives

- Sharpness with durability: San Mai knives have traits impossible to find in any other alternative. They have superb edge retention with the steel at the core and improved toughness thanks to the softer steel coat. These make San Mai blades perform exceptionally well.

- Versatility: Thanks to the design, San Mai knives are perfect for all-purpose and specialty uses. Take Kiritsuke as an example. It can replace Gyuto for some cooks that mainly slice, enabling the cook for more robust work a typical Kiritsuke wouldn’t be able to handle.

Cons of selling San Mai knives

- Experience: Building a knife blade following the San Mai technique requires years of Japanese knifemaking experience. Naturally, they come at a higher price than usual.

- Not for everyone: The features of San Mai knives aren’t for everyone. They are for frequent users that want a razor-sharp blade with improved durability. Still, home cooks can also benefit from using them.

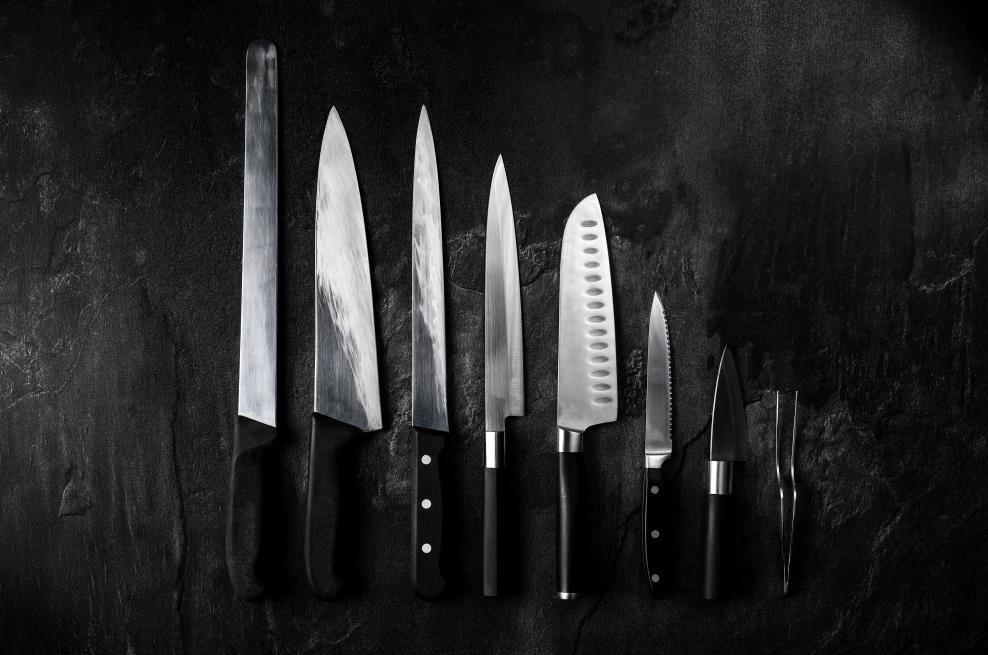

Layered steel knife vs. mono steel

First, what is mono steel? Any steel that consists of one type of steel is mono, hence the name.

As a knife material, neither is better than the other when comparing layered steel with mono steel. This is because every user has their preferences. While layered steel or a knife with cladding can improve certain qualities of a knife, some users look for a specific thing.

For example, San Mai or layered steel knives won’t have as much benefit if the user looks for the best corrosion resistance in a heavy-duty blade. German steel with relatively low carbon that has high chromium, which is mono steel, would be a more suitable pick.

The sharpness and edge retention with added toughness is efficient for frequent users. These make layered steel somewhat a better option. However, if the user has a specific feature in mind that can greatly help them, the chances are they will find mono steel more appropriate.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Should you sell layered steel knives in your store?

Selling layered steel knives tells your customers you aren’t just selling any other blade. Not every knife stores have Damascus or San Mai alternatives to their existing products.

Knife stores with customers willing to spend hundreds on a high-quality kitchen knife shouldn’t miss out on what layered steel knives offer. Damascus knives for visual attraction and San Mai for its functionality that potentially makes the best knife for frequent users.

At LeeKnives, we utilize layered steel for multiple products for wholesale and plenty of other services to go with your needs. You can order wholesale knives with private label services delivered to your storefront.

All the products you see in our catalogs are also fully customizable. Give us your specs for every product, and we’ll manufacture them for you, with your business logo engraved on each item. Click here to request a quote from us today.