Among the different types of steel used for forging knife blades, Damascus steel stands out with its appearance. It has unique looks visible across the room that can add character to any knife.

Although all Damascus blades have something different about them despite some having a similar pattern, these come in varieties. The forging method – how different steels come together – changes the entire design, producing a distinct blade.

This article will go over just that – different Damascus patterns, how they are made, a brief history of the Damascus steel, and differentiating fake from real.

Traditional Damascus steel

The way once Damascus steel was made and how it is now is different. The traditional Damascus steel or wootz steel requires ore found from Indian mine that holds a unique composition.

It was primarily produced in ancient India for centuries. Although there are methods to reproduce original Damascus steel, the process is complicated and expensive. The modern steel, also known as pattern-welded steel quickly adapted the name.

Modern Damascus steel

There are different methods to make modern pattern-welded Damascus steel, but they all follow the same principle. The blacksmiths utilize what’s known as pattern welding to forge a Damascus steel blade. Once the blade is forged, it is then ground and polished the same as any other.

However, the Damascus patterns don’t just appear as a result of this. There is more to Damascus steel than putting together multiple steel billets to forge a blade.

Buy Wholesale Damascus Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

What is a Damascus pattern?

The patterns are what make Damascus steel different from others. Regular mono steel usually has a shiny look, with some high carbon steel blades turning into a beautiful patina over time. These are also apparent in Damascus steel, but no other steel has patterns running on the entire surface.

Read more: Damascus steel vs. carbon steel

Before we get to different Damascus patterns, we first need to cover pattern welding. Understanding this forging technique helps us better comprehend how the patterns appear.

What is pattern welding?

Pattern welding is the process of mixing different steels by forging. The steel made through this process is referred to as forge-welded steel. In history, forge-welding was mainly done to produce a high-quality blade using both tough and hard steel. Forge-welding ultimately delivered a balanced knife by utilizing opposite steels that otherwise give a single attribute.

Blacksmiths today don’t need to utilize pattern welding to have a high-quality blade, as metallurgy has improved drastically. This forging method is now pretty much exclusively employed for making Damascus steel.

Although the process of pattern welding is simple, how different steel comes together to form a single steel block is up to the blacksmith. It can be forge-welded by hammering, twisting, pressing, and repeatedly doing these after one another. The Damascus patterns change as a result of different techniques of pattern welding.

However, the patterns don’t just appear out of nowhere once the steel is cool. Acid etching as the final part exposes the patterns by dipping the blade in ferric chloride – more on that below.

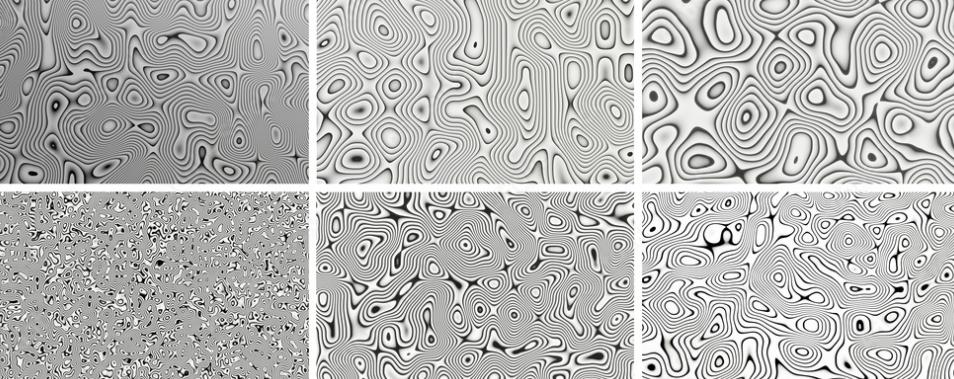

Types of Damascus pattern

Now that we’ve gone over pattern-welding, we can take a look at the different Damascus patterns and how they are made.

While every pattern-welded Damascus steel blade isn’t the same, most follow a similar pattern. Here are some of the well-known Damascus patterns.

- Cable

- Feathered

- Ladder

- Raindrop

- Shark tooth

- Spiderweb

- Twisted

Each of the patterns listed above requires different forge-welding methods. Here is what these Damascus patterns demand from the blacksmith, from bringing steels together to hammering, twisting, cutting, and more.

Cable Damascus

Perhaps the simplest pattern to make, cable Damascus requires sturdy steel cables. The blacksmith brings these short cuts of steel cables with standard welding tools and forge-welds them.

Forge-welding these steel cables is done by either hammering or pressing. As long as it is forge-welded, how it’s done doesn’t matter. That’s why the cable Damascus pattern is one of the easiest to make. Even intermediate blacksmiths getting started with Damascus patterns can do it.

Cable Damascus pattern displays curly lines running across the blade, and each twist in the steel cables makes them more apparent.

Feathered Damascus

A popular pattern, the feathered Damascus pattern demands multi-step produce to forge. About ten to fifteen small steel blocks are continuously hammered or pressed and cooled.

After forming a single steel block, the cooled steel is cut in half and forge-welded once again. This last step is done to create a straight line running across the blade. The rest are curved, small lines coming out from the straight line, resembling a feather-like appearance.

Ladder Damascus

Another straightforward pattern, ladder Damascus, requires forge-welding multiple small steel billets and cutting the unified block into bigger billets. This process can continue several times. The more it’s done, the tighter the pattern becomes.

The blacksmith first forge-welds about fifteen half an inch thick billets by pressing; then, this is cut into five one-inch billets after cooled and forge-welded again. This technique creates similar lines coming after another in a ladder-like formation.

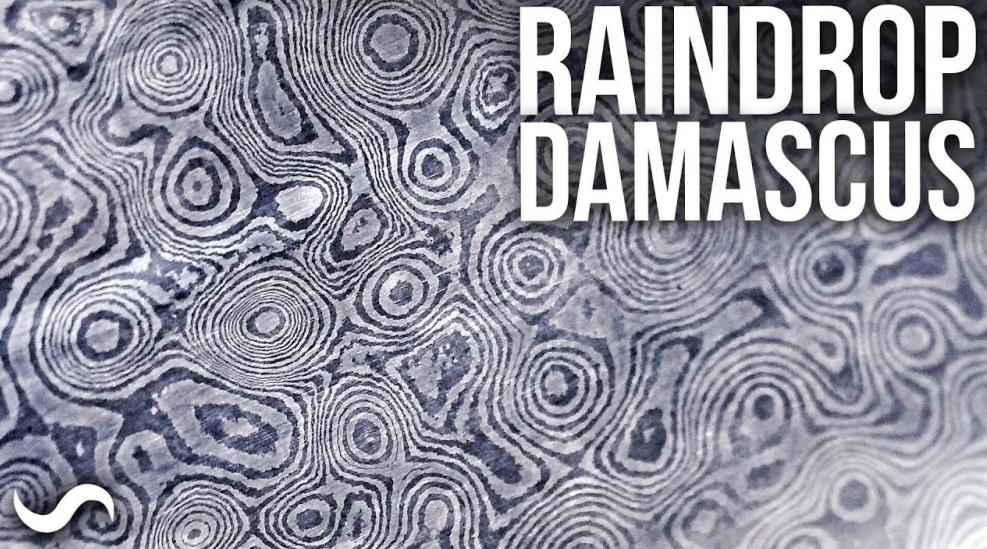

Raindrop Damascus

The process for making raindrop Damascus is comparable to the ladder pattern. It doesn’t require a second round of forge-welding, but pressing is essential. This time, however, during forge-welding, the press is applied to concentrated areas.

Since there is only so much space to press without making it like any other, the blacksmith cuts the excess. Like its name, raindrop Damascus shows mosaic-like raindrop patterns, with some areas more pronounced than others. This pattern is also easy to accomplish as it requires only basic knifemaking equipment.

This one is essentially a mix between the feathered and ladder pattern. It starts the same as the feathered pattern, but instead of cutting it in half to get the straight line, it is cut into multiple pieces and forge-welded again.

This pattern shows unified lines with a tooth-like shape at one end, similar to a shark tooth.

Spiderweb Damascus

As the name suggests, this Damascus pattern has the appearance of a spiderweb. It requires a similar process to the ladder pattern, but instead of turning smaller billets large, it starts with a square shape.

Small pieces of steel billets are forge-welded into a square shape. This square is then cut into billets, stacked, and forge-welded again. Each billet gives a spiral design that looks identical to a spiderweb. The more billets used, the more spiderwebs appear on the blade.

Twisted Damascus

The twisted Damascus steel is one of the easiest to make where the blacksmith forge-welds multiple steel billets by twisting. Every twist makes the pattern tighter. Additionally, the same as the ladder and spiderweb pattern, some blacksmiths cut the forge-welded steel and go for another round. This added forge-welding makes the designs more pronounced in parts of the blade.

This Damascus pattern is simple and provides flexibility. Beginner knifemakers can try making twisted Damascus blades before giving a shot to more complex alternatives.

Other patterns

Knifemakers can combine different forge-welding techniques to get a distinct pattern. That’s the beauty in Damascus steel knives, with each having an entirely different look distinguishable from any other.

Aside from the ones mentioned above, there are plenty of others, but many of these different patterns are a mix of different techniques. Similar to the shark tooth pattern, bringing together different styles results in distinct outcomes. These apply to diamondback, fireball, herringbone, typhoon, and other Damascus patterns.

Final step: acid etching

This is the final step of a Damascus steel blade that’s often done before assembling the handle. A knifemaker can follow different techniques to make Damascus steel all they want, but the patterns won’t arise without acid etching.

Once the excess material from the blade is ground, it is dipped in ferric chloride or hydrochloric acid. After ten to fifteen minutes, the acid exposes the patterns. Since acid etching is similar to oxidation, certain steels will show more prominent patterns than others. For example, high carbon steel will display them clearer than stainless steel with high chromium content.

Although this is the final step of making Damascus steel, knifemakers often polish the knife for a second time after acid etching. The final grinding is typically done to remove the patterns on the spine, edge, and tang. Nonetheless, this is entirely up to the knifemaker.

Since the patterns on parts of the blade are removed, this can create some confusion. Some deem these Damascus steel knife blades as fake. However, it isn’t that simple. Here is how to tell if a Damascus steel knife blade is real or an imitation.

How to tell if the Damascus steel is real

Now comes the critical part for anyone who purchased a Damascus steel knife trying to find out if it’s real. Distinguishing real and fake pattern-welded Damascus steel takes some effort. Nevertheless, there are simple ways to get an idea of whether a Damascus steel knife blade is authentic or not.

Pattern consistency

An easy way to tell if Damascus steel is real is by examining the blade. The pattern consistency is vital because every part of the blade must be Damascus steel.

At the same time, if there aren’t patterns in certain parts of the blade, this doesn’t necessarily mean it is fake. As mentioned, the knifemakers sometimes make a final polish, removing the patterns from certain parts.

In addition to this, the patterns should have a similar look. If you see a ladder pattern in one part and a raindrop in another, it’s a negative sign. The consistency of the patterns is the only way to shape an idea of authenticity, but it isn’t totally accurate.

Price

It’s a major red flag when an ad offers $20 for a Damascus steel knife. Although anyone can buy a Damascus steel knife in a variety of price ranges, they are often expensive. Even with today’s mass manufacturing, Damascus steel is labor-intensive to produce. It demands a lot of skill and experience from the blacksmith.

These drive any Damascus steel knife’s price higher. Unless bought from a reputable seller, ridiculously affordable Damascus blades tend to be fake.

Most accurate way

The most accurate method to tell if Damascus steel is authentic or fake is by acid etching the blade. Before dipping the blade in ferric chloride, there need to be areas where there aren’t patterns.

If the blade is ground after acid etching, meaning that it doesn’t have the patterns on certain parts like the edge or spine, removing them isn’t necessary. It requires some sanding if the patterns cover the blade entirely.

Here is a step-by-step guide on differentiating real Damascus steel from fake.

- Sand the blade’s tip about half an inch towards the belly to remove the pattern.

- Dip this area in ferric chloride for about ten minutes.

- Watch how the blade reacts. If the patterns slowly appear again in the same formation, it’s authentic Damascus steel.

If discoloration or random layouts appear on the blade instead of the patterns, it’s not real.

Damascus FAQs

Final words

There is no doubt about the beauty of Damascus steel knives. They are absolutely worth the extra cost even though they don’t give any practical features to the blade.

While all Damascus steel blades look astonishing, not all are equal. An inexperienced blacksmith can easily sacrifice the good qualities of the steel with aesthetics. That’s why it’s essential for knife shops to order them from reputable makers.

At LeeKnives, we offer excellent craftsmanship, providing warehouses in the US and Asia with global shipping. It’s not just physical establishments that we supply, but also dropshippers. Contact us for the blades you have in mind.