Knifemakers favor certain types of steel more than others. The users aren’t so different, either. The two commonly seen steels are carbon steel – high carbon steel more often than not – and Damascus steel. Carbon steel is a great choice for those that want excellent edge retention. Damascus steel is very versatile with its breathtaking pattern designs.

While both are satisfying choices in their respective fields, there are specific differences in the traits. This article will outline the differences between Damascus steel and carbon steel, give an idea about which one is better for your target customers, and cover more.

What is Damascus steel?

Damascus steel is a unique blade material for knifemaking. It has remarkable patterns throughout the blade. These patterns occur with pattern welding, with the help of acid etching to reveal them.

This forging method requires more than two steel blocks. The blacksmith heats the steel blocks in the forge, followed by hammering, twisting, or folding the block to mix everything. The outcome is Damascus steel. Different patterns appear as the forging method changes. For example, twisting the steel gives star-like designs that resemble mosaics.

Damascus steel is not just favored for its astonishing looks, though. Often, it’s just as practical. Since a lot of effort goes into making Damascus steel, knifemakers mainly use high-quality steel. The finished product is a knife that cuts excellently but with a significantly higher price tag.

However, not every Damascus steel is expensive. There are cheap alternatives. These are mainly made from scraps that otherwise would be thrown out. These don’t have the same quality you would find in premium-grade knife steel as you’d expect.

Ancient and modern Damascus steel

Damascus steel wasn’t made following pattern welding for the entirety of history. The original Damascus steel or wootz steel, as seen in historical blades and swords, required ore mined from India that has a high carbon composition. With impurities stretched the cementite spheroids, which resulted in patterns forming.

The methods to make and obtain this steel was successfully recreated around early 21 centuries. But wasn’t as popular as the modern pattern-welded steel.

The pattern-welded Damascus steel we refer to today shares similar patterns as the original wootz steel. They are often the Damascus steel you can see in today’s knife market.

What is (high) carbon steel

All steel has carbon. Some have as little as 0.05%; some have 2% or even more. The ones with more than 0.60% are considered high carbon steel.

These steels have high hardness and hardenability. Although excess hardness results in brittleness, making the steel less tough and susceptible to damage, tempering and other alloys like manganese help reduce brittleness.

High carbon steel is used for all types of knives, but Japanese cutlery favors them more than others. This liking mainly comes from edge retention carbon steel provides, with the refined edge suitable for making fine slices. Steel with higher carbon content tends to be harder. This allows the blade to resist dulling for longer, resulting in a knife that stays sharp for extended periods.

Damascus steel vs. carbon steel

There are a few vital points we need to clarify before comparing pattern-welded Damascus steel and carbon steel.

- Pattern-welded Damascus steel isn’t a blade material, unlike carbon steel. It’s a result of a different forging technique.

- Because of the above explanation, not every Damascus steel is the same. Damascus steel’s properties are determined by the steel used and the heat treatment done by the manufacturer.

- Like Damascus steel, not all carbon steel is the same. Some are resistant to corrosion, some are manufactured following powder metallurgy, and some are just blends of iron and carbon.

With these out of the way, here is an in-depth breakdown of how Damascus steel and carbon steel compares.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Hardness

Carbon is the primary alloy that gives steel hardness. Without carbon, hardness is an issue. High carbon steel usually has more carbon than Damascus steel.

However, high carbon steel’s carbon amount can range from 0.6% to 3%. Although this gap is large, high carbon steel in knife blades is almost always harder than their Damascus steel alternatives. On average, Damascus steel can reach high-50s on the Rockwell hardness scale. In comparison, high carbon steel tops at high-60s.

Edge retention

One aspect the steel’s hardness affects the most is edge retention. This refers to the knife’s ability to keep a sharp edge. Although it isn’t as simple – the harder the steel, the better the edge retention we expect.

However, there is an optimal point for every steel. Any steel can be heat treated to its hardest point, but the brittleness becomes an issue. It’s vital for the knifemaker to properly heat treat, then temper the steel to reduce excess hardness. Otherwise, the blade will become too brittle and chip even under slight pressure.

Damascus steel can include various alloys, and since its hardness can reach mid to high-50s, it is incredibly versatile. A Damascus steel knife can hold an edge for an adequate period. Some will do this better than certain types of carbon steel, but the majority will leave most Damascus steel behind.

Wear resistance

The wear resistance refers to the steel’s ability to resist material loss. For example, a knife blade with poor wear resistance will show scratches quickly and vice versa.

Since high carbon steel has higher hardness, it has better wear resistance. The other alloying elements are also a factor to consider. Vanadium, tungsten, molybdenum, and chromium improve the steel’s wear resistance. Such high carbon steel with a fair amount of these alloys will have even better wear resistance. The same improvement also applies to Damascus steel.

Considering Damascus steel is very diverse, it’s not a problem to have superior wear resistance than average high carbon steel. This isn’t to say that Damascus steel has better wear resistance than high carbon steel. The hardness and other alloys influence this by a large margin. Learn more about the properties of different steels here, where we cover everything mentioned for specific steels.

Knifemakers need to mind the heat treatment requirements and properties of steel and forge accordingly. With three decades of experience, LeeKnives manufactures all types of knives using a variety of steel. We ensure quick turnaround times to our partners, providing OEM and ODM services with global shipping to every corner of the world.

Durability and corrosion resistance

Undoubtedly, a good-quality knife needs to be durable. Two primary factors affect a knife’s durability the most – toughness and its ability to resist rust.

If a knife can’t absorb impact without chipping, your customers won’t be satisfied. It’s the same with corrosion resistance. A blade that rusts in a few months will be problematic, and the customers will question their choice and trust in your brand.

Usually, Damascus steel has better corrosion resistance and toughness than most high carbon steel. By standard, high carbon steel doesn’t have alloys that contribute to corrosion resistance as much. Damascus steel can have high carbon steel with stainless steel. Since carbon amount won’t be as much in Damascus steel, it will be less brittle; therefore, tougher.

The amount of chromium released into the solution during austenitizing Damascus steel may not be as much as true stainless steel. Regardless, it’s better than no chromium and positively affects corrosion resistance. For these reasons, Damascus steel resists oxidation and rusting better than high carbon steel.

Summary: pros and cons

Damascus steel knife advantages

- Damascus steel can be made with different types of steel for desired properties. The combination of possibilities is unlimited.

- The patterns running through the entire blade give them a unique, astonishing look.

Damascus steel knife disadvantages

- It’s more about looks than performance. Often, Damascus steel is favored for the patterns.

- The knives tend to be pricey, no matter the size or purpose.

Carbon steel knife advantages

- It can hold a sharp edge for long periods and is mostly sharper than most other steels.

- Generally affordable and provides more bang for the buck.

Carbon steel knife disadvantages

- Corrosion resistance could be a problem and demands more care from the user.

- It tends to be brittle, but this varies.

What about high carbon stainless steel?

High carbon steel with considerable chromium amounts is classified as high carbon stainless steel. They are the same as high carbon steel but with added chromium that enables them to resist rust better.

Despite this difference, comparisons throughout this article still apply to high carbon stainless steel. You can take everything mentioned about carbon steel the same for high carbon stainless steel, aside from corrosion resistance.

Nonetheless, high carbon stainless steel can bring the best of both worlds. They make a blade that’s resistant to oxidation and hold an edge just as long as standard high carbon steel.

Damascus steel vs. carbon steel: Which one to sell?

Undoubtedly, you and your customers will need to set aside more budget for Damascus steel knives. The multi-step manufacturing process makes Damascus steel more expensive.

Carbon steel is generally more affordable. As mentioned above, some Damascus steels are made from basic scraps. These are incredibly cheap, even compared to carbon steel at times, but as with any other product you get what you pay for.

While cost is a major deciding factor for many, it isn’t the only one. The customer’s needs and likings will largely determine which one is better. It’s up to the seller to figure out what the customers want and pick the steel accordingly.

Damascus steel is a better option for home cooks. It’s the same for those that rarely use their pocket knives. The main reason behind this is corrosion resistance. If the user is up for looking after their knives, carbon steel is the more effective and affordable option.

For pocket knives

The popularity of Damascus steel is more prevalent in kitchen knives. It makes sense for a professional chef that uses a knife for more than 40 hours a week to spend hundreds. It isn’t the same for pocket knives unless they are collectibles.

Even though anyone would appreciate a Damascus steel pocket knife’s patterns, the price can push people back. If aesthetics is one step ahead of features and price isn’t a problem for your customers, going with Damascus steel can lead to successful growth. For anything else, you wouldn’t be wrong with high carbon steel over Damascus steel.

For kitchen knives

Generally, kitchen knives get more use than pocket knives. Certain groups of people, like chefs and serious cooks, are willing to pay more for an all-purpose knife. This makes Damascus steel more suited for your business if you’re trying to reach professionals and those into cooking more than a home cook.

If home cooks on a budget are who you’re selling, high carbon or high carbon stainless steel is just as appropriate.

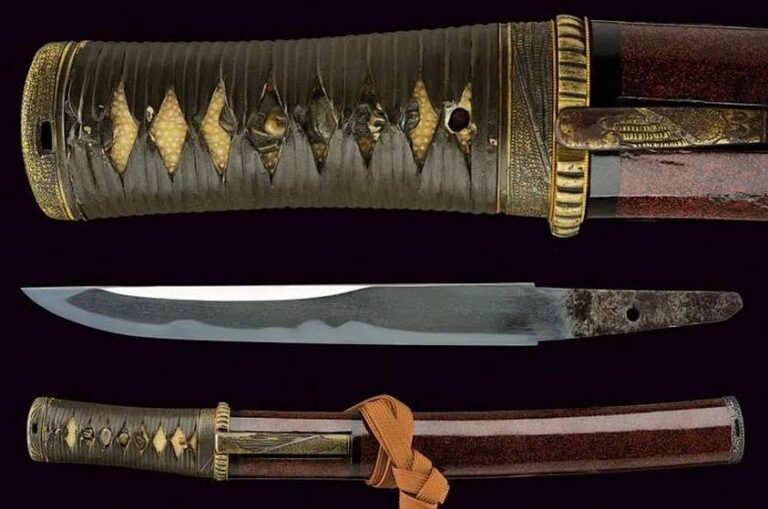

For swords & katana

Swords and katanas are a whole other world. They require more steel than kitchen knives and pocket knives. Even the largest kitchen knife blades will have less weight. This makes Damascus steel more expensive for swords and katanas.

Unless your customers are willing to pay a lot, high carbon steel with adequate corrosion resistance is a safer pick than Damascus steel.

Wrapping up

Altogether, it’s hard to compare carbon steel and Damascus steel. There is a wide range of steel that we label carbon steel and Damascus steel without covering things more in-depth.

The steel’s chemical composition, heat treatment requirements, carbide volume, and many other things affect the properties. As the properties of steel change, so do the performance you get from it.

Still, we can conclude that Damascus steel is ahead of high carbon steel for an average user that prioritizes rust resistance. High carbon steel provides more versatility to a professional that wants specific attributes, like superior edge retention over corrosion resistance. The user’s preference, type of knife, and purpose determine which one of these two is better overall.

Either Damascus or carbon steel knives, we provide both for bulk purchase and customization, contact us and get a free quote.