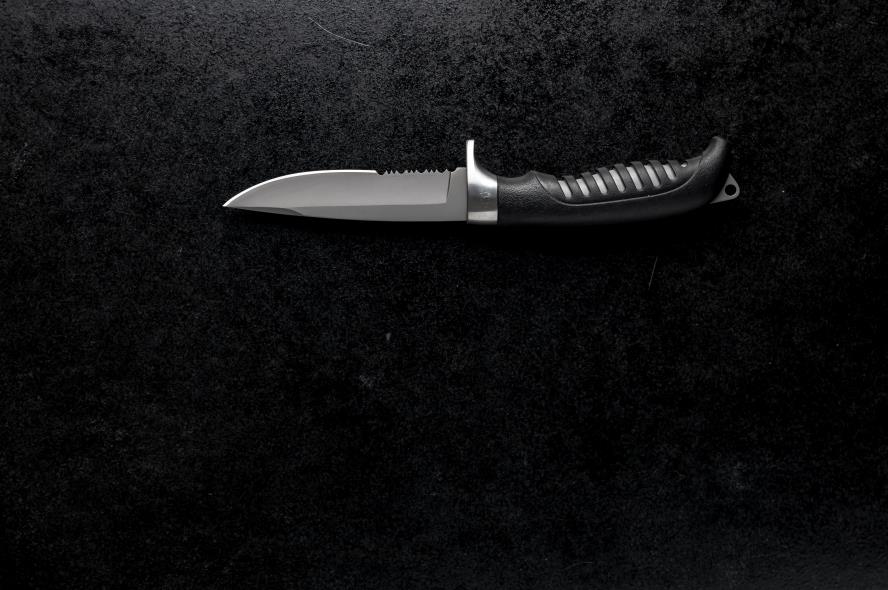

S90V is premium-grade, powder metallurgy stainless steel with high wear resistance and hardness. It has better corrosion resistance than many similar steels around the same hardness and edge retention.

S90V steel is a popular material for high-end knives of all kinds. The knives forged from this steel are expensive, not just because of the associated cost of purchasing the steel, but it also takes an experienced blacksmith to bring out its full potential.

Here is everything you need to know about S90V steel in this article. We’ll cover its properties to determine if S90V steel makes a good product for your knife store or far exceed your customers’ expectations.

S90V composition

- Carbon (C): 2.30%

- Chromium (Cr): 14%

- Vanadium (V): 8.75 – 9.00%

- Molybdenum (Mo): 1.00%

- Manganese (Mn): 0.50%

- Silicon (Si): 0.50%

- Tungsten (W): 0.40%

Aside from the carbon & chromium content that makes up the blade, the high vanadium in S90V’s mixture is what separates itself from other high-end steels. It promotes the formation of high vanadium carbides that achieve superb wear resistance.

S90V characteristics

S90V has incredible edge retention thanks to high wear resistance, leaving many others behind. These two are the main properties of S90V steel, but there is more to it. Here is what to expect from an S90V knife, covering the essentials.

Hardness

S90V can reach an impressive hardness of 66 HRc after quenching. However, S90V steel is too brittle at this rate with the amount of vanadium carbides. So it needs tempering to reduce excess hardness and relieve internal stress, S90V steel has an optimal hardness between 57 and 60 HRc.

Since there is a significant difference between its quenched and tempered hardness, heat treatment can pose difficulties. If you’re planning to purchase knives made from this steel, it’s vital to source them from experienced manufacturers.

Surely, S90V steel’s hardness doesn’t sound impressive as plenty of other knife steel has the same hardness. What S90V has that others don’t is hidden in its other hard-to-come-by traits.

Edge retention

S90V has one of the best performing edge retention out of all stainless steel. A CATRA testing by Larrin Thomas shows S90V steel is second only to the much harder alternative S125V – also manufactured by Crucible. It’s common to hear S90V as CPM S90V, referring to Crucible Particle Metallurgy.

With such good edge retention, average users can forget about sharpening their blades for considerable periods. S90V is one of the best steel picks for frequent users. Think professional chefs and outdoor enthusiasts.

Even with regular use, S90V steel knives won’t need sharpening for many months. In the hands of an average consumer, it will take a considerable time before the blade sees the surface of a whetstone.

Wear resistance

S90V owes this superb edge retention to its wear resistance. It’s incredibly challenging to wear down S90V steel. The knife blades won’t show scratches for months. Even following frequent use, S90V knives maintain their shiny looks.

The edge retention also impacts the ability for it to be sharpened. S90V knives, whether for kitchen use or outdoors, won’t get dull quickly but eventually will. When they do, it’s very challenging to bring their glory back to life.

An average user with a basic whetstone will have hardships giving S90V knives a razor-sharp edge. Using coarse or diamond whetstones results in easier sharpening but can lead to microchips. Recommend your customers to let a professional sharpener do the job when required.

Toughness

As a general rule of thumb, there is a fall in toughness when edge retention and wear resistance are high. This applies to S90V, but not to the highest degree.

S90V steel has satisfying toughness for its high edge retention and wear resistance. The powder metallurgy process helps S90V achieve increased toughness than similar alternatives.

Other options with similar edge retention and wear resistance achieve these properties with high hardness. S90V accomplishes it mainly due to the hard vanadium carbides. S90V steel is hard, but not too much that it’s very brittle. These make S90V steel have decent toughness.

For context, S90V steel’s toughness is similar to 440C, D2, and VG-10.

Corrosion resistance

S90V steel’s ability to resist corrosion is sufficient for use in knives. It isn’t as great as German knife steel but satisfying for most users. Under regular use, S90V won’t rust or display other oxidation forms.

Although chromium and vanadium fight to form carbides, there’s a good balance between the two. S90V has enough vanadium carbides for substantial improvements in wear resistance without sacrificing corrosion resistance. Overall, S90V is stainless steel with satisfying rust resistance abilities.

S90V steel comparison

Many refer to S90V as super steel with balance properties that favor edge retention and wear resistance. Here is how S90V stacks up against the best alternatives to it.

S90V vs. S30V

Crucible manufactures both S30V and S90V. S30V has less carbon and vanadium than S90V, with the same amount of chromium but more molybdenum. The composition of S30V enables it to have better toughness and corrosion resistance than S90V. S30V steel doesn’t hold an edge as great as S90V but is considerably easier to sharpen.

S30V makes a more affordable knife for average users, like home cooks and occasional campers. S90V beats S30V in edge retention, as expected. This difference alone makes S90V steel a more fitting choice for more professional and frequent use.

S90 vs. S110V

S90V and S110V are almost identical steel with similar properties that don’t exhibit many differences. S110V has slightly better edge retention and wear resistance, but S90V is tougher and more corrosion-resistant.

However, these differences are only minimal. They both make great knife blades following proper heat treatment. If the edge retention of S90V doesn’t cut it, S110V is superior. For everything else, S90V is more suitable for every use case.

S90V vs. VG-10

In knife steel used for kitchen knives, VG-10 is a very prevalent choice, particularly with Japanese blades. VG-10 makes a versatile blade that won’t chip easily. It’s incredibly tough, rust-resistant, and sharper compared to S90V steel.

If you’re planning to sell Japanese kitchen knives, VG-10 suits the purpose better. For outdoor knives, S90V is a more sensible pick that gets users further in edge retention and wear resistance.

VG-10 proves its worth with proper edge retention and easy sharpening for knives that require resilience against impacts.

S90V applications

Ever since Crucible started manufacturing S90V in 1996, it has been a popular name for forging high-end knives. However, its wear resistance made it favorable for many other applications.

According to Crucible, S90V’s applications include gear pumps, injection molds, valve components, nozzle inserts, pelletizing equipment – and of course – industrial knives, cutters, and specialty cutlery requiring edge retention.

Is S90V a good choice for your knife business?

S90V steel is premium-grade stainless steel. It’s a solid knife steel choice for stores selling products to frequent users. S90V knife steel’s edge retention is enough to convince anyone using their knives daily for hours.

In some ways, its edge retention can be overkill for average users. A home cook or someone looking for an EDC will surely appreciate the properties of S90V. However, there are just as good alternatives for their use frequency at affordable price ranges.

S30V, 154CM, and S45VN are a few good examples. Learn more about other knife steel from here.

Buy wholesale knives from LeeKnives

S90V or any other knife steel, you can purchase all types of knives in bulk from LeeKnives. We also do custom orders – redesign an existing product, or create an entirely new one with your specifications. We’ll use the materials you asked for, manufactured down to the smallest detail, and delivered to your storefront with the desired packaging.

LeeKnives is ready to be your only supplier. Contact us to request a quote for our services.