In the US market, Shun is a standard for high-quality Japanese knives. For sellers building a quality brand, this raises a key question: where and how are Shun knives made?

Shun knives are handmade in Seki City, Japan. They are a top brand of the KAI Group, a Japanese company with over 100 years of history in making blades.

Understanding how Shun makes its knives is a masterclass in building a premium brand. This guide looks at their strategy, where they make their knives, and the lessons you can apply to your business.

Shun’s Brand Strategy: Quality and a Real Story

Shun’s strategy is built on a clear promise: mixing traditional Japanese skill with modern, high-performance technology. Unlike brands that only use a Japanese style, Shun’s identity is tied to its real, proven origins.

This strategy is clear in their different product lines:

- Shun Classic & Premier: These are the core of the brand. They feature an exclusive VG-MAX steel core with Damascus layers, balancing great performance with strength.

- Shun Narukami: This line uses a high-carbon “Blue” steel core for amazing sharpness. It targets users who know how to take care of traditional carbon steel.

- Shun Dual Core: Made with 71 layered pieces of VG10 and VG2 steels, this series has a unique look and a hard, strong edge.

By offering these special lines, Shun proves its knowledge of materials and targets different parts of the premium market.

Manufacturing Origin: Seki City, Japan

Shun knives are made only in Seki City, Japan. This choice is the anchor for their entire brand. Seki is a complete center for knife production with a deep history.

A History of Blades

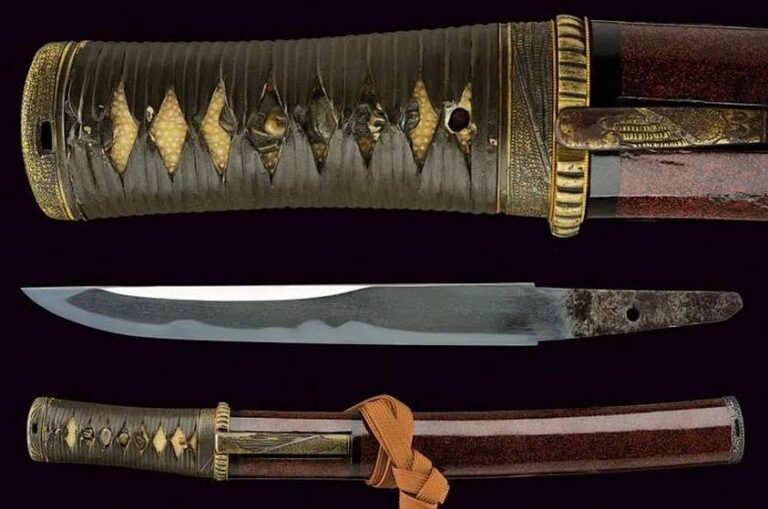

Seki City became a center for sword-making in the 13th century. When carrying swords was banned in the 1800s, many sword makers used their skills to make cutlery. This allowed the craft to survive. The Kai Group, Shun’s parent company, was founded in Seki City in 1908.

The Handmade Process

Every Shun knife is made using a mix of old traditions and new technology. Each knife goes through at least 100 steps, combining machine work with careful hand-finishing by skilled workers.

How to Spot a Real Shun Knife

All real Shun knife blades are made in Seki City, Japan, and are marked with “Handcrafted in Japan.” Some accessories, like a wooden sheath (saya), may be made in China, but the blade itself is always made in Japan.

Shun Knife Reviews: A Lesson in Steel

Customer reviews for Shun are very positive, but a common complaint offers a key lesson for sellers about high-performance steel.

| Common Praises | Common Criticisms |

| Very Sharp Edge | Blade Can Chip if Misused |

| Real Japanese Look & Finish | Higher Price Point |

| High-Quality, Premium Materials | Needs Careful Maintenance |

The Key Takeaway for Sellers: The Hard Steel Trade-Off

The most common complaint, chipping, is a direct result of Shun’s greatest strength. Their blades use very hard Japanese steel (often 60-61 HRC) to hold a super sharp edge. But harder steel is less tough and can be brittle, so it might chip if used on bones or frozen food.

This is a key lesson: your choice of steel defines your customer. A brand using hard steel must teach its customers how to care for it. A brand for rougher use should choose a tougher, more forgiving steel.

Read More:

Learn all about the different materials in our [Complete Guide to Japanese Knife Steel].

- A Real Story is Your Anchor: Shun’s story works because it’s true. A real origin story, backed by your manufacturing choice, builds trust and supports a higher price.

- Materials Define Your Customer: Shun’s hard steel is for cooks who want sharpness more than toughness. Your steel choice is a key decision that decides who your ideal customer is.

- A Strong Foundation Builds Trust: Shun’s link to the KAI Group gives them trust. As a new brand, you build trust by being honest and choosing a reliable, expert manufacturer.

Launch Your Custom Knife Line Faster with LeeKnives

Complete OEM/ODM support—from design to final shipment—so you can focus on growth.

Backed by warehouses in the U.S. for fast, reliable delivery.

Leeknives: Your Partner in Manufacturing

Shun built its brand by choosing a location that matched its story. Your brand needs a manufacturing partner that fits your goals.

For sellers who need to balance quality, custom designs, and value, Yangjiang is the right choice. At Leeknives, we produce all types of quality knives.

- Material Knowledge: Whether you need a tough, German-style blade or a high-performance knife using imported Japanese VG-10 steel, our factory can source and produce it.

- Full Design Options: We help you build a brand with real, multi-layered Damascus or a cost-effective cosmetic pattern. Your strategy decides the product.

- Direct Factory Partnership: We provide the direct communication and quality control needed to build a brand you can be proud of.

Build Your Brand with a Direct Factory Partner. Contact Leeknives for a Quote Today.