Whetstones are hands down the best tool for sharpening a knife. They sharpen blades distinctively different from other sharpening tools.

Whetstones can also achieve more than bringing back the sharpness of a blade, depending on the grit. Whetstones with different grits can repair damaged edges, refine the already sharp cutting edge, and polish the blade.

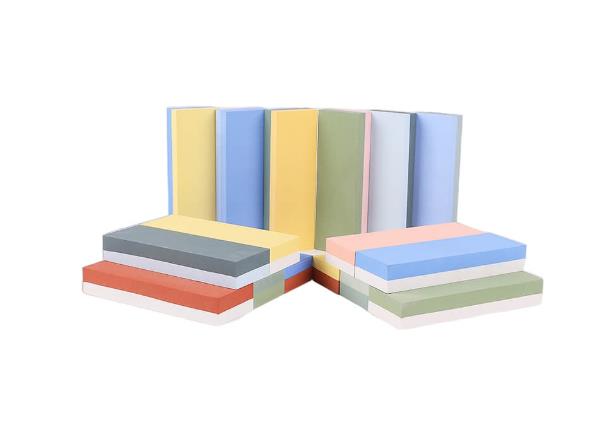

Once you decide on the type of whetstone to display in your store, grit is the second most important detail. Offering a variety of sharpening stones with different grits is a must for any knife store. These tools make your customers’ purchases worthwhile, enabling shoppers to use them for various needs.

This article will discuss everything you need to know about whetstone grit and what to expect from sharpening stones with ranging grit sizes while providing insights into finding the most appropriate sharpening product for your store.

What is whetstone grit?

Whetstone grit is a way of measuring the coarseness of the surface. The grit measures the grain size of the abrasive materials on the whetstone. It’s essentially the same as sandpaper grits. The lower the figure, the coarser the whetstone, and vice versa.

There are three main classifications of whetstone with ranging grits. These are known as coarse, medium, and finishing stones.

However, there isn’t a standard for where a whetstone falls within the above. The user preferences determine this. For one user, a 750 grit whetstone may not be coarse enough, deeming it a medium stone. For another, this can be coarsest than ever. While these come down to user preferences, there are some industry benchmarks.

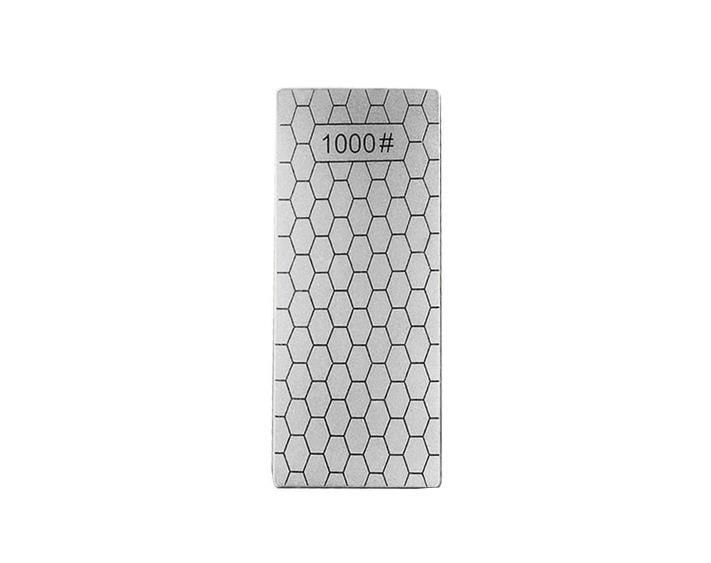

Many manufacturers and users classify coarse whetstones as below 1,000 grit, medium stones between 1,000 and 3,000, and finishing stones above 3,000 grit.

Buy Wholesale Sharpening Tools and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

How do whetstones work?

Before examining whetstones with different grits, let us first cover how sharpening stones work for a better understanding.

Whetstones sharpen knives by removing material from the cutting edge to create a brand new one. Every stroke on the sharpening stone removes material, shedding the old, broken edge. This process exposes an untouched surface on the cutting edge.

The coarser the stone, the easier this happens. However, some blade materials can have a hard time withstanding the abrasiveness. Before you know it, the whetstone creates microchips rather than smoothly shedding material from the edge.

This is one of the reasons why whetstones come with varying grits – accommodating different knives and what the user wants to accomplish.

Whetstone types based on grit

Here’s a detailed breakdown of how coarse, medium, and finishing whetstones help with sharpening and other related tasks.

Coarse stone

Coarse whetstones are for repairing chipped edges and sharpening extremely dull blades. They remove the most material at the fastest rate.

Sharpening or repairing a knife with these whetstones must be done carefully. Most knife blades don’t have enough tensile strength to resist the abrasion caused by these whetstones, which can further damage the blade.

However, this isn’t to say all coarse whetstones are for experienced sharpeners. There is a significant difference between the abrasion caused by 1,000 grit and 300 grit whetstone.

You can recommend an appropriate range to your customers, depending on how dull the blade is and the severity of the chip. A 500 grit whetstone to repair; 1,000 grit whetstone to quickly sharpen a dull knife, for example.

Main uses

- Repairing damages

- Sharpening wear-resistant blades

Medium stone

Medium stones are the intermediary between coarse and finishing stones – higher than 1,000 but lower than 3,000 grit. A whetstone in this grit size is appropriate for most knives aiming to achieve a sharp edge.

Even though their primary use is for sharpening dull knives, these whetstones can be used to refine an already sharp edge to a smaller extent. They can also be used as a coarse stone to repair a very dull edge, but that may take much more time and elbow grease.

Main uses

- General sharpening

- Refining the cutting edge

Finishing stone

Finishing stones have the finest grains out of three. These whetstones are for polishing the edge to take the sharpness of a knife one step further. Finishing stones are also perfect for polishing blades to remove scratches, bringing back their shine.

A finishing stone takes the sharpened edge and polishes away the tiny flaws a coarse or medium stone creates with each stroke. It boosts the already sharp edge by making it consistent and smooth throughout.

The use of a polishing stone is optional for most knife users, but utilizing them enhances sharpness greatly. After a few minutes of stroking on the finishing stone, any knife can be potentially sharper than the factory. Most polishing stones are between 3,000 and 6,000 grit, but you can get plenty that are up to a fine 30,000 grit.

Main uses

- Polishing the already sharp edge

- Getting rid of scratches and other marks on the blade

Whetstone grit chart

| Grit | Uses |

| 150 and below | Repairing blades |

| 150 to 400 | Sharpening incredibly dull knives |

| 400 to 1,000 | Sharpening dull knives |

| 1,000 to 3,000 | General sharpening – best sharpening for most knives |

| 3,000 to 6,000 | General polishing – best for polishing most knives |

| 6,000 to 10,000 | Polishing to achieve a razor-sharp cutting edge |

| 10,000 to 30,000 | Polishing the blade delicately – perfect for that mirror polish |

How to recommend a whetstone to your customers?

The grit size is undoubtedly important, but there is more to whetstones – and there isn’t one whetstone type. When choosing the right sharpening products to display in your store, you’ll also need to select what kind of whetstone to sell.

Types of whetstone

Water stone

Water stones require water as a lubricant. Most water stones are made from silicon carbide or aluminum oxide. These sharpening stones need to be soaked in water before use. This process is for filling the air bubbles to prevent cracking. The coarser the whetstone, the longer it needs to stay submerged in water. For example, a 100 grit whetstone will need more time to soak water.

When sharpening a knife with a water stone, the surface wears down. The worn materials – both from the blade and whetstone – blend in with the water and create a slurry. This slurry creates further abrasion, helping the knife get sharpened faster.

Oil stone

Oil stones need oil as a lubricant, usually mineral or honing oil. Unlike water stones, these whetstones don’t need to be soaked. They aren’t porous and have a rough texture. The oil prevents dry friction that can heat and damage the cutting edge. Like water stones, oil stones create a slurry that helps with sharpening.

It’s essential to let your customers never mistake the two. Using oil on a water stone will mess up the pores, leading to imperfections and making it useless. Oil stones are usually made from novaculite, also known as Arkansas stone.

Diamond stone

Diamond stones, on the other hand, are different from both water and oil sharpening stones. They don’t require any lubricant but must have a clean surface before using. If the pores are clogged, diamond stones must be thoroughly cleaned with a brush and soapy water.

Since these whetstones are coated with diamond, they are the coarsest and can be a tad bit too much for general sharpening work. Yet, these stones are the best remedy for fixing disastrous chips. Primarily, professional sharpeners use diamond stones the most. Even those who sharpen their blades regularly don’t need diamond stones, except for repairing blades.

Best whetstone to sell

Water stones are a fitting sharpening product choice for most knife stores. They can sharpen all types of knives swiftly, are easy to use, and don’t require anything special to begin sharpening. Your customers are all set to sharpen their prized blades with just a few splashes on the surface.

Since grit determines many features of the whetstone, we recommend selling double-sided ones. These whetstones have one grit size on one and another on the opposite side. For example, 400 grit to sharpen dull knives or repair chipped edges and 2,000 grit to refine the sharpness.

A multi-purpose whetstone like this is the right candidate for being the top-selling sharpening product in any knife store.

Buy Wholesale Sharpening Tools and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Other tools of sharpening

It’s not only whetstones that give knives a sharp edge. There are other tools for sharpening; some are even more popular than whetstones.

Although whetstones are a favored sharpening tool to many, using them can be too much work for some. For these customers, the following sharpening tools tend to be more convenient.

Honing rods

Honing rods made from steel don’t necessarily sharpen the edge per se. Instead, they create a temporary micro bevel that makes the edge sharper, but the bevel will fade away quickly. Doing this wears off the material on edge, and will damage the blade performance in the long run.

For the above reason, honing rod is only appropriate under time-sensitive circumstances. Such as a cooking showdown you see on TV where professional chefs hone their knives all the time.

Ceramic or diamond coated honing rods, on the other hand, bring the same result as a whetstone.

Manual sharpeners

Most sharpeners work similarly to honing rods. They create a micro bevel, but some have abrasive slots that wear the blade down. This process isn’t as complete or perfect as whetstones. Still, sharpeners deliver noticeable results enough for home cooks.

Some of the sharpeners even work with single bevel knives. However, sharpening a single bevel knife isn’t as straightforward. Read this article on how to sharpen single bevel knives.

There are also electric versions of these gadgets. With one press of a button, users can run their knife from heel to tip rather than moving the blade back and forth in the slot.

Source sharpening products from LeeKnives

Selling products related to sharpening and knife maintenance is a nice addition for every knife business. If you’re someone who owns or manages a knife store, we are ready to be the only supplier you will ever need.

At LeeKnives, we manufacture various sharpening tools that satisfy users of all levels and skillsets. Our wide range of sharpening products can be used for sharpening and upkeeping kitchen knives, pocket knives, and large blades.

Browse our wholesale knife sharpening products from here to see the product specifications, MOQs, and details about customizations. We have whetstones, manual sharpeners, honing rods, and other tools.

Interested in a product? Click here to request a quote now.