When you’re sourcing knives, you have one main question: “Can this partner deliver quality, at scale, reliably?”

The answer lies in a 5,000-year history.

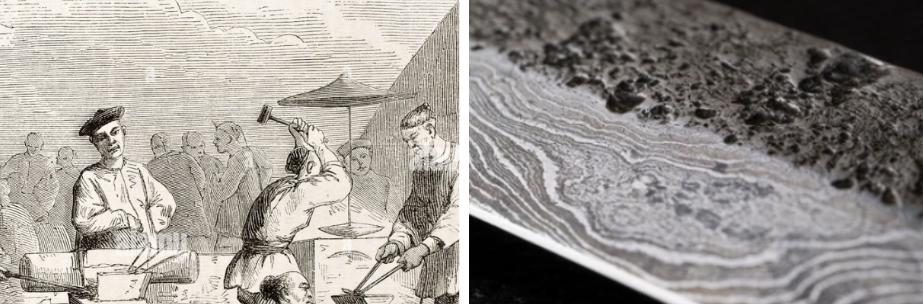

For any brand in the knife business, understanding the history of Chinese cutlery isn’t just for trivia. It’s how you verify the deep expertise, massive scale, and manufacturing maturity of your supply chain.

This article will walk you through the key moments of this history.

The Evolution of Chinese Knife Manufacturing

| Period | Key Development | Significance for Modern Manufacturing |

| Neolithic Period | Stone Tools | Establishes the fundamental human need for a sharp edge. |

| Bronze Age | Bronze Alloy | The first material revolution: humans begin to “design” alloys. |

| Han Dynasty | Steel Revolution & State Standards | The birth of Mass Production and Quality Control (QC). |

| Age of Division | New Steelmaking Tech (Perfusion) | The key technical bridge that enabled the next “golden age” of steel. |

| Tang Dynasty | Peak of Craft & Steel Tech | Advanced steelmaking created high-performance, specialized tools. |

| Song Dynasty | Civilian Tool Innovation | The “pivoted scissor” invention, opening a massive new market. |

| Yuan Dynasty | Influence of Nomadic Styles | Cemented the curved saber as the dominant military blade style. |

| Ming & Qing | Military Standardization | The peak of pre-industrial “standard-issue” production. |

| Modern Era | Global Manufacturing Hub | Yangjiang rises as the OEM/ODM center, mastering global steels. |

Prehistory & Bronze Age (c. 10,000 – 221 BC)

It started with a need. In the Neolithic Period, the first Shi Dao (stone knives) were flaked from quartz.

The first true material revolution was the Bronze Age, when smiths learned to “design” alloys. Bronze could be cast into complex shapes (like Bronze Swords) and was far less brittle than stone.

By the Warring States Period, tools became specialized, like the Xue Dao (carving knife) used by scribes to scrape errors off bamboo slips.

Han Dynasty: The Steel Revolution (206 BC – 220 AD)

The Han Dynasty was the first “explosion point” for Chinese cutlery. It marked the full transition to the Iron Age and established the concept of industrial standardization.

- Industrial Standards: The state-run “Iron Offices” mass-produced high-quality steel weapons, acting as an early form of large-scale quality control (QC).

- Military Innovation: The

Ring Pommel Knife(Huanshou Dao) was the result. This long, single-edged steel blade was a devastating cavalry weapon whose design influenced blades for the next 1,000 years. - Household Tools: This era also gave us the

V-shaped spring shears, the earliest known scissors in China.

Age of Division: The Birth of Better Steel (220 – 589 AD)

(Three Kingdoms, Jin, and S/N Dynasties) This 400-year period of constant conflict created immense pressure for arms innovation.

The most critical development was the invention of Guan'gangfa (perfusion steel).

This technique solved the core problem of ancient metallurgy: brittle high-carbon cast iron vs. soft low-carbon wrought iron. By melting the two together, smiths could efficiently produce high-quality steel. This technology was the engine that would power the next era of blade-making.

Tang Dynasty: The Golden Age of Craft (618 – 907 AD)

If the Han was the industrial revolution, the Tang was the renaissance. Fueled by the mature perfusion steel technique, Tang smiths created legendary blades.

The era was defined by specialization:

- Military Tools: The military relied on the curved

Cavalry Saber (Dao)for slashing and the massive, two-handedModao(infantry sword) designed specifically to sever a charging horse’s legs. - Status Symbols: The straight-bladed

Jianbecame a symbol of status and scholarly refinement, separate from its battlefield role. - Civilian Tools: For civilian use, the

8-shape shear(the pivot-pin prototype) became common as paper use spread.

Song Dynasty: The Shift to Civilian Tools (960 – 1279 AD)

During the Song Dynasty, civilian life and urban culture flourished. The most important innovation of this period was the perfection of the pivoted scissors (Jiaogu Jian) with a rivet.

This simple lever-based design was a huge leap in efficiency, creating a powerful tool for every household and tailor.

As firearms began to appear, the focus of high-end blade-smithing also shifted heavily toward the civilian and kitchen markets, with specialized chef knives (Chudao) becoming common.

Yuan Dynasty: The Influence of the Steppe (1271 – 1368 AD)

The Mongol-led Yuan Dynasty brought a strong nomadic influence.

The curved saber (wan dao), long favored by steppe cavalry for its superior slashing ergonomics from horseback, became the undisputed dominant military blade.

This Central Asian influence solidified the saber’s form over the traditional straight sword (jian) in military use, a trend that would continue for the next 600 years.

Ming & Qing: The Peak of Standardization (1368 – 1912 AD)

This final imperial era was the grand finale of the cold-weapon, defined by military standardization. The Qing Dynasty had strict regulations, resulting in the most organized and complex catalog of pre-industrial blades:

- Standard Saber (Peidao): The standard-issue curved saber for most soldiers.

- Heavy Sword (Dadao): A large, two-handed weapon used by infantry.

- Complex Classifications: Dozens of other official models existed, like the

Wo Dao(a curved saber with a Japanese influence),Zhanmadao(a large anti-cavalry sword), andHuya Dao(Tiger Tooth Sword), each for a specific branch.

This was the last era of the blade as a primary weapon. As firearms took over, this massive industrial knowledge turned fully toward civilian use.

Republic Period: The Last Echo (1912 – 1949 AD)

The role of the blade in warfare was over. But it had one final, symbolic moment.

The Anti-War Big Knife (Kangzhan Dadao)—a simple, rugged, and easy-to-produce heavy blade with a ring pommel—was used by Chinese soldiers in close-quarters combat during the Second World War.

It was a powerful symbol of resistance and the last major case of traditional Chinese blades being used in war.

Modern Era: The Legacy Concentrated in Yangjiang

When traditional blades left the battlefield, their manufacturing legacy didn’t disappear. It was concentrated and transformed in the civilian sector, most notably in Yangjiang.

While Yangjiang’s own craft history spans 1,500 years, it was in the modern era that it became the “Capital of Knives and Scissors.” After the 1980s, the industry moved from state-run factories to a dynamic market of private enterprises. These factories embraced global trade, invested in modern CNC machinery, and focused on becoming the world’s premier OEM/ODM partners.

Today’s Manufacturing Ecosystem

This city is not just a location; it is the living result of China’s 5,000-year history of manufacturing. It is a complete and efficient ecosystem defined by scale:

- Enterprise Cluster: Over 2,600 knife-related companies.

- Industrial Scale: An annual output value of over ¥52 Billion RMB.

- Market Share: Produces 70% of all knives in China.

- Export Dominance: Accounts for 85% of all knives exported from China.

This ecosystem means that everything—from specialty steel sourcing and precision heat treatment to CNC grinding and packaging—is available in one efficient hub.

From Ancient Legacy to Your Production Line

This 5,000-year history—from Han Dynasty industrial standards to Tang Dynasty steel tech—is essentially a story of “precision manufacturing.”

It’s about turning raw materials into reliable, consistent, high-performance tools. When you partner with Leeknives, you are connecting directly to the modern essence of this legacy.

We are not just another factory in Yangjiang; we are your end-to-end supply chain solution, built specifically for the needs of US brands. We combine the cost advantages of our manufacturing heritage with the efficiency and market understanding you expect.

Here is what sets us apart:

- From Concept to Delivery, One Team: Whether you have a finished design or just an idea, our in-house team of designers and engineers works with you. We provide a complete one-stop solution, from optimizing your blueprints and selecting the right materials (from high-end US CPM S35VN/S90V to high-value 8Cr13MoV) to final production and quality control.

- Yangjiang Cost + US Efficiency: We offer the best of both worlds. While your knives are crafted with the cost advantages of Yangjiang’s mature supply chain, our US-based warehouse handles the complex logistics for you. This ensures your products reach the market quickly and reliably, reducing your inventory pressure and shipping headaches.

- Deep Market Insight: We have a long history of providing OEM services for well-known American brands. We understand the US market intimately—especially how to balance performance, cost, and craftsmanship to create products that consumers in the entry-level and mid-range markets truly value and buy.

Ready to build your next product line on a 5,000-year foundation of craft? Contact us to discuss your manufacturing needs.