Crucible’s CPM S35VN steel is an upgrade over the popular S30V. It has improved toughness without compromising wear resistance and edge retention. S35VN steel stands over many others in the market, making it a favorite among knifemakers and users alike.

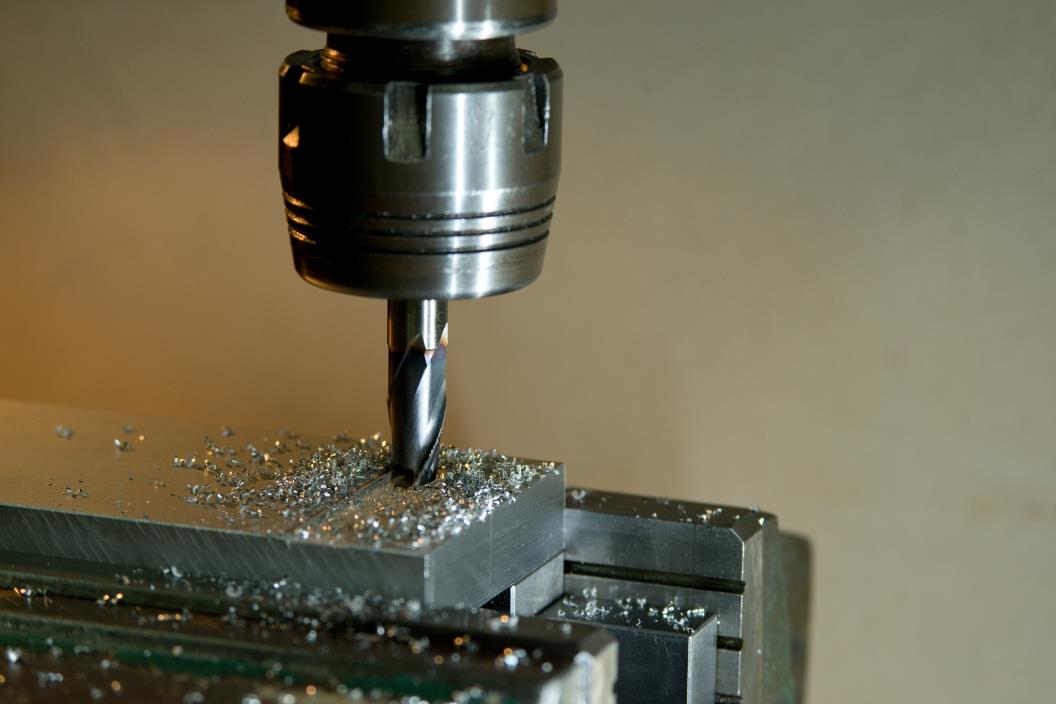

Like the CPM S30V, S35VN is a powder metallurgy steel. The steel that undergoes the powder metallurgy gets a fine, uniform grain structure. This enables the steel to deliver exceptional sharpness with improved edge retention, wear resistance, and toughness.

As you can expect, S35VN knife steel holds up to these. It is strong and holds an edge for satisfying periods. However, as with any other knife steel, there is much more to discuss.

This article will cover all aspects of S35VN steel, including its composition, properties, and more. Read to the end to determine if selling knives made from S35VN would be a good investment for your knife business.

S35VN steel composition

S35VN has a very similar composition compared to S30V. But is much tougher than the latter thanks to the Niobium addition – the element that represents the letter N in S35VN’s name.

| Percentage | Contribution | |

| Carbon | 1.40% | Increases hardness and strength |

| Chromium | 14.00% | Improves corrosion resistance and toughness |

| Vanadium | 3.00% | Improves hardness and wear resistance |

| Molybdenum | 2.00% | Increases hardenability, toughness, and tensile strength |

| Niobium | 0.50% | Improves toughness and refines the steel |

| Cobalt | 0.50% | Increases hardness and strength, improve hardenability |

| Nitrogen | 0.10 – 040% | Increases hardness |

S35VN steel properties

S35VN knife steel has properties that might surprise you. Let’s dive deep into its properties to discover what kind of blade CPM S35VN makes.

Hardness

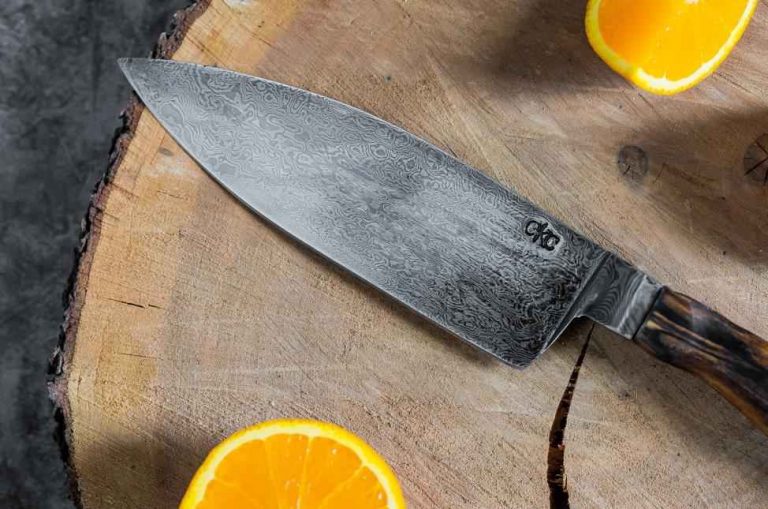

The typical hardness for CPM S35VN is between 58 and 61 HRc. Crucible also recommends knifemakers aim for this range. This hardness is ideal for various cutlery, from all-purpose chef’s knives to the delicate Yanagiba.

However, CPM S35VN knives sacrifice toughness and durability as the hardness increases. Continuous robust use doesn’t suit this knife steel as highly tough steels like 5Cr15MoV. Sure, it can tackle cutting tasks that require brute force, but it might disappoint over time. For the best results, S35VN should be heat treated carefully.

Edge retention

Relatively high hardness, vanadium content, and improved wear resistance are enough to convince any knife enthusiast about a blade’s edge retention. Compared to many knife steels, the CPM S35VN is more than satisfactory in this regard. For reference, S35VN holds a sharp edge longer than 154CM, 440C, D2, and 420HC.

This level of edge retention makes S35VN ideal for pretty much all types of knives. From slicers to paring knives, S35VN delivers a blade that cuts for extended periods.

While it’s above many others, it falls short of premium knife steels like S90V, SG2, and Aogami Super.

Wear resistance

As mentioned, CPM S35VN steel has improved wear resistance than S30V. Since the S30V already has good wear resistance, S35VN steel takes this further. The wear resistance of S35VN helps blades resist scratches and marks caused by impacts over time while improving edge retention.

Although S35VN blades maintain a scratch-free appearance, sharpening may pose a problem. Sharpening an S35VN knife using a standard sharpener or a honing rod won’t get users far. Advise your customers to invest in a high-quality whetstone with an S35VN knife. If you’re not selling whetstones already, check our sharpening supplies.

Toughness

Despite the edge retention and wear resistance S35VN has, it doesn’t have a significant drop in toughness. S35VN steel has better durability than many steels in the same hardness range.

Furthermore, Crucible created the S35VN with this in mind. The company improved toughness to supply blades with better resistance to edge chipping without losing edge retention.

That said, S35VN has satisfying toughness for most purposes. It’s unlikely to experience chipping using a knife made from this steel when chopping, slicing, or even carving foods. Although it isn’t the perfect cleaver material, S35VN is suitable for forging larger blades.

Corrosion resistance

Rust and corrosion aren’t a problem with S35VN steel. At 14 percent, the chromium content in its chemical composition is well-above what’s considered minimum for stainless steel. Even in humid climates, it is unlikely to corrode or rust.

Using an S35VN knife in the kitchen to cut acidic foods or exposing it to damp environments is perfectly fine. Cooks can comfortably use S35VN knives to cut saltwater fish, citrus, pickles, and other ingredients that can corrode knives without worry.

In outdoor applications, the corrosion resistance of S35VN doesn’t disappoint either. However, it isn’t the best choice for knives specifically designed for marine environments, such as diving knives.

One important note about the corrosion resistance of S35VN is it can be reduced if tempered at high temperatures. Knifemakers must maintain temperature control during heat treatment to prevent reducing corrosion resistance.

Price

S35VN isn’t particularly expensive, but it’s certainly not budget steel. As with any other steel manufactured following powder metallurgy processes, S35VN has an increased price. If you’re seeking budget-friendly products, the price of S35VN knives may be surprising, even when purchasing in large quantities.

Nonetheless, the price of S35VN is justifiable considering its properties. You can sell knives made from this steel that fit the budget of most shoppers.

Summarizing S35VN steel’s knife performance

- Impressive edge retention: S35VN provides blades with excellent edge retention that meets the needs of most users. It exceeds expectations for recreational use, but professionals might prefer something better.

- Fair toughness: S35VN creates a tough and durable blade that resists chipping. It can handle various tasks with ease, from slicing to carving.

- Good corrosion resistance: Corrosion and rust concerns are minimal with S35VN blades. However, it isn’t the best choice for specialty marine knives.

- Challenging sharpening: S35VN knives require a careful sharpening process with whetstones to get a sharp edge. Once the blade is dull, a honing rod or a typical sharpener won’t help much.

- Various applications: S35VN steel is a good fit for making diverse blades, from kitchen cutlery to EDC knives. Most knives made from S35VN steel, however, are kitchen knives.

- Moderate pricing: Depending on the manufacturer, a typical chef’s knife can cost anywhere from $15 to $40 wholesale.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

S35VN steel vs. other steel

Now that you have an idea of what to expect from S35VN steel, here is how it compares to similar alternatives.

S35VN vs. CPM S30V

S30V is the predecessor to S35VN. They share many similarities, but some differences set them apart, which can be deciding factors for shoppers.

S35VN and S30V have equivalent chemical composition, with the exception of 0.50% niobium in S35VN. This addition provides S35VN with better wear resistance. While this happens, S35VN doesn’t lose any of its toughness.

The primary difference between S35VN and S30V is the improved wear resistance. Both still have a similar degree of toughness and corrosion resistance, while S30V is slightly superior in terms of edge retention.

S35VN vs. 154CM

Like how S30V is the predecessor to S35VN, 154CM is a modified version of 440C. It has balancing properties that are perfect for forging blades of all kinds. 154CM steel is also manufactured by Crucible Industries.

S35VN steel is superior to 154CM in almost all aspects except for sharpening ease. S35VN has better corrosion resistance, edge retention, durability, and sharpness. 154CM is a few steps down from S35VN but comes with a much more affordable price tag.

154CM is still a strong option with its affordable pricing and balanced properties. If you want to offer your customers budget options that won’t disappoint, 154CM steel knives can make one of the best-selling products. As an even more affordable alternative, opt for 10Cr15CoMoV instead.

Should you invest in this steel?

S35VN steel boasts well-balanced properties that none outweigh the others. It doesn’t have excellent edge retention that brings down toughness, for example. This harmonious blend of properties makes S35VN knives appeal to a diverse range of shoppers.

Overall, S35VN steel makes a good-quality knife. You can find this steel in high-end kitchen knives that get regular use to EDC knives that are always ready for action.

These make S35VN steel a sensible investment for knife stores catering to customers buying products for everyday use. If the pricing is a problem and you want similar attributes, there’s always the S30V as the closest alternative.

Source knives from LeeKnives

LeeKnives is a knife manufacturer based in Yangjiang City, one of the global hubs for cutlery. We are ready to be the only supplier you will ever need with our extensive catalog featuring kitchen knives, cutting boards, flatware, sharpening equipment, and much more. Contact us today, get a free quote, and see our work in action!