Good quality kitchen tools will always be in high demand since people will unlikely stop eating any time soon. Expanding towards other kitchen accessories is a natural step for a knife shop owner, but choosing your products carefully is essential.

Cutting boards are a great addition to any shop in this niche. With such a broad range of options and a massive customer base, they’re a quick and nearly effortless way to increase your profits.

It’s been proven that wood is safer than most other materials, but that still leaves you with countless options. The best wood for a cutting board will depend significantly on user preference, so let’s look into the various types and explore where each excels.

How to choose a wood cutting board for your store?

There are several factors one should consider when buying a wooden cutting board. Whether your customers like to do their “homework” on every item they purchase or buy more based on whim, it’s up to you to offer them the best products.

Even though wood is safer than plastic or glass, The National Sanitation Foundation still found that 18% of the sampled cutting boards harbored bacteria like Salmonella and E.coli.

Proper sanitization is the user’s responsibility, but contamination can be easily avoided with suitable wood types.

When deciding on a product, you should generally consider three critical factors.

Wood hardness

The hardness and density of the wood will decide a board’s durability and resistance to impact and scratches. It also influences how quickly a knife will become dull with repeated use.

The wood’s hardness will also determine whether the board has a level of bounce to it, which some customers consider when making their purchase.

Wood porosity

Hardwoods have pores that transport water throughout the tree, while softwoods use tracheids for hydration and the production of sap. Here are the types of pore patterns:

- ring-porous

- semi-diffuse porous

- diffuse-porous

- non-porous

The first three patterns pertain to hardwood, while non-porous usually refers to softwood. With all patterns, the pores can be small or large, but a ring-porous pattern will usually have the largest pores.

This means that the wood will have a high absorption rate, making the board more susceptible to moisture damage. Some good examples of this are oak and ash wood.

Woods can also be classified as open-grain or closed-grain. Open-grain pores are visible to the naked eye, while the pores on closed-grain woods are only visible with magnification.

Since a cutting board must stay as dry as possible, close-grain woods are the safest choice.

Wood toxicity

Some wood species, such as tropical hardwood trees, produce toxins to keep insects and microbes at bay. Using a cutting board made of those could seep the natural toxins into the food, so they should be avoided at all costs.

Generally, woods cut from trees that produce edible nuts or fruit are safe options. You should also ensure that the boards’ finishes, like oils or glues, are entirely safe for preparing food.

Frequent customer concerns

Not every customer will dive deep into research when deciding on a cutting board. Some questions you should consider include:

- Is the board knife friendly? How will it dull my blade over time?

- Is it high-maintenance? Will I need to oil or condition this board regularly?

- Is the board durable? How well does it resist scratches or dents?

- Is it easy to clean? Can I quickly sanitize it?

- What does it cost? What am I getting for my money?

Settling on a robust cutting board selection means striking the perfect balance between quality, practicality, and costs. A savvy entrepreneur will choose a few reliable options that cover many preferences while remaining accessible to various budgets.

Buy Wholesale Cutting Boards and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Hardwood vs. softwood

Right off the bat, there are a few reasons why hardwood is a superior choice for cutting boards. They are the most durable and won’t easily scratch or dent. They also have little give, which makes a cook’s life a bit easier.

Depending on the type of steel used when making a knife, both softwood and hardwood can negatively impact its sharpness.

What’s Janka wood hardness?

The industry-wide standard for rating the hardness of a type of wood is known as the Janka test, named after American researcher Gabriel Janka.

The test measures the amount of force required to embed a 7/16 inch steel ball halfway into a sample of wood, which would produce a circle with an area of one square centimeter.

The hardness of the sample varies with the direction of the wood grain. When testing a sample perpendicular to the grain, the result is known as “side hardness,” while tests done on the cut surface of the wood provide the “end hardness.”

Results are stated in units of force, and they differ across the globe. For example, in the United States, the measurements are in pounds-force (lbf), while in Europe, they are stated in kilograms-force (kgf).

While there isn’t a formal delimitation between the two, woods rating under 1000lbf on the Janka scale are considered soft and those rating above are thought of as hardwoods.

When it comes to cutting boards, the optimal harness is considered between 900 and 1500lbf.

What’s silica in wood?

Silica is a natural compound, most abundantly found in the earth’s crust. It is composed of silicon and oxygen and, in many parts of the world, it is the main constituent of sand.

There are a few tree species that have silica in their wood, making them potentially harmful to cooking utensils.

A silica concentration of more than 0.5% in wood can damage cutting tools, but that’s rarely an issue with cutting boards and it mostly refers to the metal equipment used for harvesting the trees.

Softwood and temperate tree species have negligible amounts of silica in their wood, but some tropical hardwood species like teak can have higher levels in their composition.

Even so, most of the silica content is found in the bark, the outermost layer of stems and roots. And so this compound is generally not an issue for a finished cutting board.

Best cutting board wood

Ebony

Untreated ebony has been used successfully for a variety of kitchen products, like spatulas, chopsticks, and, of course, cutting boards. It is one of the hardest types of wood out there, with a 3,220 lbf Janka hardness score.

The best ebony wood is weighty and derived from heartwood only. It has a beautiful dark color that hides stains and a wonderful, even grain pattern.

One of the densest types of wood available, ebony is very resistant to moisture, scratches, and even impact. Its high oil content acts as an additional barrier for liquids and bacteria. However, it can have a noticeable dulling effect on knives.

One of the biggest selling points of ebony cutting boards is their impressive aspect, but many appreciate them for their high durability.

Of course, you should expect these boards to come at a higher price range, due to their popularity and the relative difficulty it poses for processing.

Pros

- Dense and very durable, resistant to scratches.

- Visually appealing with a natural luster.

- Water-resistant and easy to maintain.

Cons

- High price point.

- Will dull knives faster than other wood types.

Acacia

Acacia trees grow primarily in Australia, although some species can be found in Asia and the Pacific islands. Most commercial species have moderate weight and a medium to dark brown color.

Although its sourcing is so localized, there are more than 160 different Acacia varieties, each with their own hardness level. Some species, such as the Acacia Mangium and Acacia Malanoxylon barely pass the 1000 mark on the Janka test, while some species mark impressively high rates.

For example, Acacia Acuminata, which features a lovely reddish hue, scores a 3,100 Janka hardness, while Acacia Cambagei goes up to 4,270 lbf.

Despite these differences, many acacia strains are fantastic choices of wood for cutting boards. They are generally water resistant, very durable and resistant to adverse conditions and impress many customers through their aspect.

Pros

- Acacia wood strains generally feature beautiful color and patterns.

- Most acacia woods are hard and durable, not prone to scratches or scarring.

- There are many options of acacia to choose from, fitting many different advantages and designs.

Cons

- Acacia woods are slow drying with and present a risk of deformation with time.

- Acacia woods are more expensive compared to other hardwoods.

- There is a higher risk of cracking and splintering, considering the wood’s general hardness.

- With so many different strains to choose from, customers might get inaccurate information and wrong expectations about the acacia strain you’re selling.

Teak

Teak is a very popular option for cutting boards, and it has been long prized for its durability. Rating a 1,070 lbf on the Janka scale, this tropical hardwood is known for its resistance to scratches.

A unique feature of teak wood is that it retains its natural oils after it’s been processed, making it water-repelling. Combined with a tight, close-grain, this makes a teak cutting board effortless to clean and sanitize.

Its resistance to water also prevents the board from warping after several washes, so teak cutting boards can last for decades.

It’s worth mentioning that teak isn’t the most sustainable option, though. Their popularity led to a massive reduction in wild teak trees, with the African teak becoming an endangered species.

Pros

- It has a high resistance to deformation.

- Teak is water-repellent and easy to sanitize.

- Very resistant to scratches and scarring, although not the friendliest to expensive knives.

Cons

- High porosity, although the natural oils prevent moisture damage.

- Not a sustainable option.

Buy Wholesale Cutting Boards and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Maple

Maple must be one of the most popular choices for cutting boards, specifically sugar and hard maple. It is a hard (1,450 lbf), closed-grain wood with tiny pores and is neutral in color.

A maple cutting board is lightweight and durable but not too harsh on knives.

The closely packed grain does not allow it to absorb moisture too quickly, which makes boards effortless to wash and dry.

Moreover, maple wood is naturally antimicrobial, so it will generally be the perfect choice for customers concerned with safety.

Maple is more scratch resistant than teak or walnut, but it will also shrink more with a decrease in humidity. This means that maple boards should be conditioned monthly or even more frequently, depending on the climate.

One downside is its light color, making the boards susceptible to permanent stains.

Pros

- It is very durable and scratch resistant.

- The wood features a visually pleasing color and grain.

- Naturally anti-microbial, food and allergy-safe.

Cons

- Susceptible to deformation unless conditioned frequently, so buyers should be knowledgeable of the maintenance cost and ready to pay it.

- Maple is also susceptible to insect attacks, which can turn some buyers off, especially when it comes to food-related items.

Cherry

Cherry wood is a balanced choice for cutting boards since it ticks a lot of boxes on practicality. It is dense enough to sustain heavy use but soft enough to keep knives in top condition.

Sitting at about 995lbf on the Janka scale, cherry wood is a bit softer than walnut.

The fine, straight, closed-grain pattern of cherry wood is very similar to maple both in aspect and functionality. It is water resistant and quick to recover from knife scarring.

Its medium to dark color is recognizable and easily hides stains, with the wood being easy to care for, overall.

Pros

- Reasonably durable and resistant to shock or deep scratches.

- Will preserve a knife’s sharpness for longer.

- Attractive color and grain.

- Easy to maintain.

Cons

- Much softer than the common alternatives.

- Can be more expensive than similar options, such as Maple wood.

Walnut

Walnut is the opposite of maple in that it is a heavy, soft, and closed-grain wood. With deep, dark colors, walnut cutting boards can hide any stain and will preserve their beauty for many years.

Yet, the softness of walnut also makes the boards easier to scratch or dent than in the case of maple. That isn’t a huge drawback, since they are still quite durable, rating a 1,010 lbf on the Janka scale.

Apart from their visual appeal, walnut cutting boards are also friendlier with knives, striking the perfect balance between knife maintenance and board resilience.

Pros

- Attractive color and grain.

- Gentle with knives, preventing them from becoming dull.

- Reasonably durable.

Cons

- Discoloration can occur in contact with iron.

- Low moisture resistance.

- Usually expensive.

Larch

Larch is a sustainable, highly-sought after type of wood since it is fast to mature and very resistant to adverse environmental conditions. It is the dominant species of the boreal forests of Canada and Siberia.

A resilient and durable choice for a cutting board, larch wood is also quite flexible, measuring a mere 830 on the Janka test. This makes larch cutting boards easy on the knives, and allows them to self heal.

Although the wood is quite dense, it is technically a softwood, so it won’t splinter or crack, even on impact. It is important to note, however, that larch wood presents a risk of deformation with time, especially when it is not dried properly.

Pros

- Larch wood is easily available and sustainable.

- Larch cutting boards are knife friendly and can self heal, while also being resistant to shocks and heavy daily use.

- Larch wood is naturally antimicrobial and rot-resistant.

- Although soft, larch wood is dense enough to be very sturdy and durable.

Cons

- Larch cutting boards can deform over time, and they are not as resistant to moisture as other wood types.

- Due to its popularity, larch is generally more expensive than other wood types.

Beech

Beech is a popular wood for cutting board, counter tops and chopping blocks due to its relative low cost and all-around advantages. It might not be the most exciting wood type when it comes to aspect, but it gets the job done.

It is similar to maple in terms of functionality, with a diffuse-porous pattern, straight grain and balanced hardness. Scoring a rating of 1300 on the Janka scale, beech wood is very durable, although it tends to shrink with use and cleaning.

One of the most budget-friendly options, beech also comes with the disadvantage of a pale color, making cutting boards very susceptible to persistant stains.

Pros

- Beech is widely available and inexpensive.

- It is a very popular choice for cutting boards and other kitchen utensils due to its hardness and durability.

- Beech has very small pores, making it quite resistant to moisure.

Cons

- Beech can shrink with time and will easily stain due to its light color.

- Due to its fine pores, it can be difficult to oil and is generally harder on the knives. For this reason, it can be avoided by people who use more expensive knives.

What is wood grain?

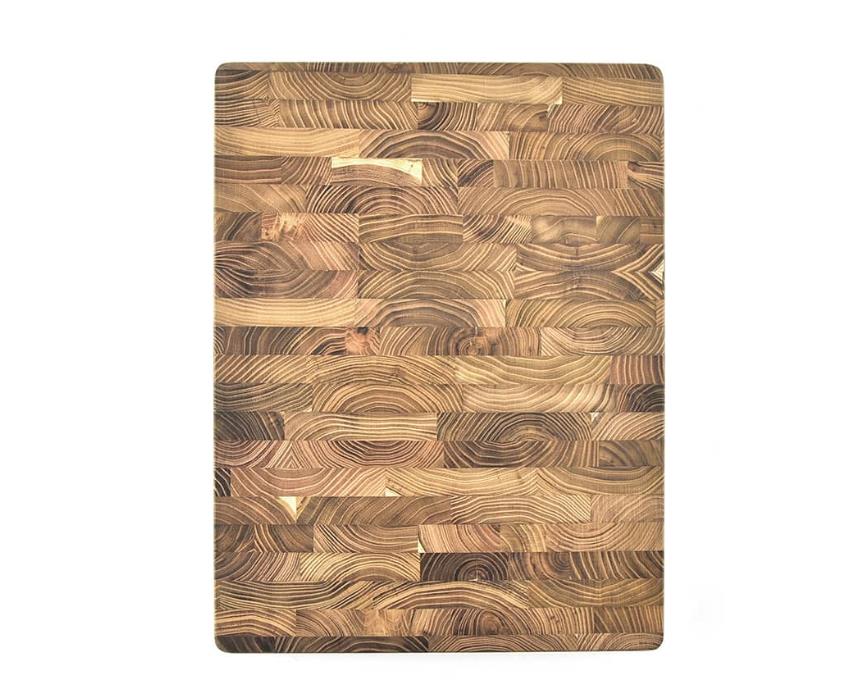

Depending on the cutting layer of the wood, boards are generally classified as edge grain, face grain and end grain.

Edge grain cutting boards are made of wood that has been cut alongside the grain, so the cutting surface would show long wood fibers.

On the other hand, end grain boards are made by fussing cross-sections of wood together, creating a surface that shows the rings of the wood. They are generally thicker and take longer to make, which is why they come with a higher price tag.

Many people seem to confuse edge grain with face grain, which makes for a slightly different product. We get a face grain when one side of the board is bigger than the other – the wide side is then reffered to as the face, as opposed to the edge.

Should you sell wood cutting boards in your store?

If you already have a shop up and running, you would probably be missing out by not selling cutting boards. They are such simple items to provide in a variety of materials, sizes, and designs.

Since they are indispensable for any household, you won’t have any issues finding customers for them, and you can even market them as extras for your higher-end knives.

It’s true that quality cutting boards don’t see many repeat customers, and that should be a testimony to the durability of the products you offer.

However, an established customer base won’t take too long to decide on buying such a staple, and happy clients will always return to buy gifts for their loved ones.

Depending on the type of customer your stores sees everyday, you might want to look into very different products to add to your inventory.

For example, face grain acacia boards have a beautiful rustic aspect on top of their functional advantages. This makes them perfect for selling to customers who care a great deal about design.

They can elevate the look of a kitchen and are excellent for charcuterie boards (and Instagram pictures).

End grain teak boards satisfy the same craving, and they come with the added benefit of Internet hype. The beautiful end grain pattern fits boards of all sizes and styles, which has won this type of cutting board a spot in many culinary magazines and shows.

But there’s more to these boards than their looks, since many users will testify to their excellent durability and practicality. A huge selling point of these boards is that they need little to no maintenance.

Of course, the hardness of these boards takes a toll on expensive knives, so they won’t be the first choice of chefs who don’t care much about design.

Buy Wholesale Cutting Boards and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Wrap up

Some of the biggest factors that influence a customer’s decision when it comes to cutting board remain the durability, knife friendliness, as well as its aspect.

We are visual creatures, after all.

Depending on your audience, you might choose some wood types over others, but they all make great, reliable options.

If you’re catering to an audience that has no problem throwing a few hundred dollars at a quality piece, you might want to go for the more exclusive options, such as ebony or walnut.

However, with a great design under your belt, you can turn a robust profit even from the more mainstream options, such as maple or cherry.

If you’re still not sure, it won’t hurt to include a budget, mid-range, and higher-end option, granted they check most boxes for practicality.

Yet, since most sales will be driven by customer preference, you can rest assured that any of these woods will do great in your store, as long as you put a little effort into showcasing their qualities.

Ready to expand your store listing and make sells with wood cutting boards? Contact us to get a quote on premium cutting board wholesale.