When selecting materials for your knife brand, industry terminology can be confusing. Many buyers ask: “Is Damascus steel better than carbon steel?” or “Should I choose stainless or Damascus?”

To make the right business decision, you must first understand one thing: Carbon Steel and Stainless Steel refer to the chemical composition of the metal, while Damascus refers to the manufacturing process of the blade.

This guide breaks down the logic behind these materials to help you choose the best solution for your brand positioning.

What is the Real Difference? (Material vs. Construction)

To make a strategic sourcing decision, you must distinguish between what the steel is and how the blade is arranged.

Think of it like a building:

- Carbon or Stainless Steel are the materials (the bricks and wood). They determine the fundamental properties like strength and weather resistance.

- Damascus Steel is the architecture (the blueprint). It describes how those materials are layered and stacked together to create the final structure.

A common mistake is treating Damascus as a third “type” of steel alloy. In reality, Damascus is a construction method that can utilize either carbon or stainless steel as its “ingredients.”

Table 1: Steel Categories vs. Manufacturing Methods

| Category | Type | Definition | Common Examples |

| Material Property | Carbon Steel | Focuses on chemistry (high carbon, very low chromium). | 1095, White Steel |

| Material Property | Stainless Steel | Focuses on chemistry (contains at least 10.5% chromium to prevent rust). | VG10, AUS-10 |

| Manufacturing Process | Damascus Steel | Focuses on blade structure (layering and forging multiple steels together). | Pattern-welded steel |

- The Core Logic: Damascus is a carrier of performance, not the performance itself. You can choose a Carbon Damascus for traditionalists who want an evolving patina, or a Stainless Damascus for premium brands that require modern rust resistance.

Understanding this distinction allows you to tell a better story to your customers: You aren’t just selling “Damascus”; you are selling a high-performance material (like 10Cr15CoMoV) wrapped in a professional-grade architecture.

Carbon Steel

What is Carbon Steel?

Carbon steel is the “performance benchmark” of the knife world. Its composition is simple, consisting mainly of Iron and Carbon (usually 0.6% to 1.5%). Unlike stainless steel, it does not contain high amounts of chromium.

- Why can carbon steel get sharper? Under a microscope, carbon steel has a very fine and uniform crystal structure because it lacks “grainy” chromium carbides. This allows the edge to be ground to a physical limit—thinner and more consistent than stainless steel. For professional chefs seeking the ultimate cutting feel, this “bite” is irreplaceable.

- For a detailed look at the most successful commercial carbon steel, see our Review of 1095 Steel.

Pros & Cons

- Pros:

- Extreme Sharpness: Can reach very high hardness (HRC 62+) with a incredibly fine edge.

- Fast Sharpening: Despite its hardness, the pure structure allows sharpening stones to work quickly and effectively.

- Superior Feedback: Chefs can feel the food fibers breaking through the blade, which is core to high-end positioning.

- Cons:

- Highly Oxidizable: It will discolor or rust within minutes of contact with moisture or acidic foods (like onions or lemons).

- High Maintenance: Requires strict cleaning, drying, and regular oiling.

B2B Insights

- Build a Professional Barrier: If your brand is positioned as “Handcrafted” or “Traditional Japanese Craft,” carbon steel is essential. It attracts “hardcore” users willing to pay for performance and maintenance.

- Inventory Risk: Brands must be aware that carbon steel requires high-humidity control in warehouses. For long shipping routes, packaging must include desiccant and rust-preventive oil coatings to avoid rust spots upon delivery.

If your target market is professional chefs, you must also provide them with education on How to Take Care of Carbon Steel Knives and what to expect regarding the development of Patina.

Stainless Steel

What is Stainless Steel?

Stainless steel is the industry standard for modern kitchenware. To be classified as “stainless,” the steel must contain at least 10.5% chromium. Chromium reacts with oxygen to form an invisible, microscopic Passive Layer on the surface.

- Stainless steel is not “rust-proof”; it is “self-healing.” When the surface is scratched, chromium immediately reacts with oxygen to regrow the protective layer. However, to achieve this, the steel forms large chromium carbides. These “particles” increase wear resistance but make the edge slightly “coarser” at a microscopic level, creating a “sticky” feel during sharpening.

Pros & Cons

- Pros:

- Superior Durability: Requires almost no special maintenance; perfect for humid commercial kitchens.

- Food Safety: Meets strict global hygiene standards (like NSF) and won’t produce a metallic taste from oxidation.

- Better Toughness: Compared to carbon steel, stainless is less likely to chip when hitting bone or hard surfaces.

- Cons:

- Sharpness Ceiling: While modern high-end stainless is excellent, it still lags slightly behind premium carbon steel in microscopic sharpness.

- Sharpening Challenges: Prone to developing a “burr” that is difficult to remove, requiring better sharpening skills from the end user.

B2B Insights

- Lower After-Sales Costs: This is the highest-volume category globally. For brands on Amazon or in retail, stainless steel significantly reduces returns caused by rust complaints, providing a foundation for steady growth.

- Premium Performance: Brands can use high-performance stainless (like high-quality Cr-Mo-V steels) to provide carbon-like hardness (HRC 58-60) while remaining rust-resistant. This is the profit core of most high-end modern brands.

To understand the differences between the two most common categories, read our more detailed Carbon Steel vs. Stainless Steel Comparison.

Damascus Steel

What is Damascus Steel?

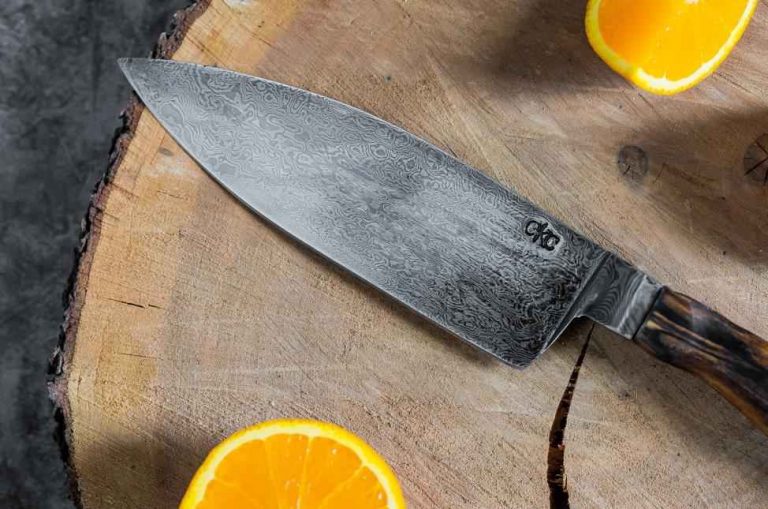

In modern manufacturing, Damascus (Pattern-Welded Steel) is a composite structure technology. It is created by forge-welding different types of steel together—usually a high-hardness core and high-toughness outer layers.

- Core Principle: Imagine a supercar. The Core Steel is the engine (decides cutting speed and sharpness); the Cladding is the body (decides appearance and impact resistance).

- The Truth About Layers: Common 67 or 33-layer structures are created by folding stainless steel around the center core. This creates a unique pattern and acts as a microscopic “shock absorber.”

Pros & Cons

- Pros:

- Mechanical Synergy: It solves the “hard yet brittle” problem. The hard core (like 10Cr15CoMoV) handles the cutting, while the multi-layered cladding provides toughness to prevent the blade from snapping.

- Rust Balance: Even if the core is carbon steel, using stainless cladding significantly improves the overall rust resistance.

- Extreme Premium Value: Patterns are a natural anti-counterfeiting mark. Every knife is unique.

- Cons:

- Manufacturing Complexity: Improper temperature or pressure during forging leads to Delamination, a major quality risk in B2B sourcing.

- Sharpening Care: While it cuts well, improper sharpening can scratch the expensive etched pattern.

- High Cost: The waste rate is much higher than single-layer steel.

B2B Insights

- Perceived Value vs. Actual Cost: Damascus knives often retail for 3-5 times the price of single-steel knives, but manufacturing costs usually only increase by 1-2 times. This makes it the highest-margin category for brands looking to upgrade their image.

- Lower Education Barrier: Compared to pure carbon steel, Stainless Damascus saves brands from “rust prevention education” costs. It satisfies the customer’s desire for a “professional tool” while being as easy to clean as standard stainless.

- Supply Chain Stability: Don’t just look at the layer count. The Core Steel material (e.g., whether it is genuine 10Cr15CoMoV or AUS-10) and the stability of heat treatment are what decide your brand’s reputation.

For a deeper dive into its history, read our article on What Is Damascus Steel: Origin and Composition.

How Do They Compare?

To help you visualize the differences, the table below compares Carbon and Stainless steel benchmarks against Composite Damascus.

Table 2: Knife Steel Performance Matrix (Scale 1-5, 5 is Best)

| Metric | Premium Carbon (e.g., 1095) | High-Performance Stainless (e.g., 440C) | Composite Stainless Damascus (e.g., 10Cr15CoMoV) |

| Edge Retention (HRC Potential) | 5/5 (HRC 62+) | 3/5 (HRC 56-58) | 5/5 (HRC 60-62) |

| Corrosion Resistance | 1/5 (Rusts easily) | 5/5 (Very strong) | 4.5/5 (Excellent) |

| Sharpenability | 5/5 (Very easy) | 2/5 (Sticky feel) | 3.5/5 (Clear feedback) |

| Toughness (Anti-Chipping) | 2/5 (Hard but brittle) | 4/5 (Moderate) | 5/5 (Layered protection) |

| Manufacturing Cost (OEM) | Low | Medium | High |

Which Steel Should Your Brand Choose?

As a factory, we recommend brands select materials based on their target market, not just price:

- For Professional Chef Brands: Focus on Carbon Steel or High-Carbon Damascus. These users know how to maintain a knife and prioritize a “wicked sharp” edge.

- For Premium Home Brands: Stainless Damascus is the top choice.It provides the “wow” factor of various Damascus patterns with the practicality of stainless steel.

- For Mass Market/Retail: High-quality Single-layer Stainless Steel provides the best profit margin and lowest return rates. Factory Tip: If you want Japanese VG10 performance at a better price point, 10Cr15CoMoV Damascus is our most recommended solution for OEM projects.

Ready to Start Your Next Project?

Choosing the right steel is only the first step. At Leeknives, we understand the real challenges brands face in the supply chain: heat treatment stability, pattern consistency, and finding the precise balance between cost and performance.

As experts in Yangjiang knife manufacturing, we provide more than just OEM services:

- Material Strategy Consulting: Whether you seek the extreme performance or a cost-effective stainless solution.

- Custom OEM/ODM: From private labeling to fully custom blade designs and pattern development.

- Rigorous Quality Control: Every batch undergoes HRC hardness testing to ensure your knives meet your brand’s reputation.

Want to turn your brand concept into a high-quality product?

- Get a Quote: Contact our engineers today for the latest bulk pricing based on your selected steel.

- Evaluate Samples: Personally test the sharpness and feel of our 10Cr15CoMoV Damascus sample series.

Contact the Leeknives Expert Team Now.

Frequently Asked Questions

Is Damascus steel better than carbon steel?

Direct Answer: Damascus steel is not inherently “better” in cutting performance, but it offers superior mechanical synergy.

While pure carbon steel provides a fine, uniform edge, modern Stainless Damascus combines a high-performance core (like 10Cr15CoMoV) with multi-layered cladding. This construction allows a knife to achieve a high hardness (HRC 60-62) for the edge while maintaining the overall toughness and fracture resistance that monolithic carbon steel often lacks.

Does Damascus steel rust easily?

Direct Answer: Rust resistance depends on the steel chemistry, not the pattern.

Traditional Carbon Damascus (typically made of 1095 and 15N20 steel) is highly susceptible to oxidation and requires regular oiling. However, modern Stainless Damascus utilizes high-chromium alloys. These blades are as corrosion-resistant as premium stainless steel because they form a protective chromium oxide layer, making them much more practical for the modern mass market.

Why choose Damascus for a knife brand?

Direct Answer: Damascus steel provides instant market differentiation and a “premium” brand narrative.

From a B2B perspective, Damascus patterns serve as a natural anti-counterfeiting mark and significantly increase the perceived value of the product. This allows brands to justify a higher price point and achieve better retail margins. It is the most effective material for brands looking to bridge the gap between “functional tool” and “luxury collector’s item.”