G10 has been gaining popularity in recent years for its unique properties and applications, particularly in the world of knives. You may have come across this term while browsing for a new knife and wondered what it means. In this article, we’ll explore what G10 material is and why it has become a sought-after choice for knife handles.

G10 is a high-pressure fiberglass laminate, made by stacking layers of glass cloth, soaked in epoxy resin, and compressing them under heat and pressure until they solidify. The result is an incredibly strong, lightweight, and moisture-resistant material. In the context of knife handles, G10 has several advantages. For one, its strength ensures that your knife will have a sturdy and durable grip. Additionally, G10 is known for maintaining its shape and stability under varying temperatures and humidity levels, which is crucial for a tool that may be exposed to different environments.

Designers and manufacturers have embraced G10 for its versatility, offering knife handles in a wide range of colors, textures, and patterns. This allows you to select a knife that not only performs well but also suits your personal style. Now that you understand the gist of G10, we’ll examine the material closer below, and help you decide whether it’s the right choice for your business. Read on to find out!

What Exactly Is G10

As we’ve explained a bit above, G10 is a type of composite material made from woven glass cloth combined with an epoxy resin. This combination results in a highly durable and strong material that is resistant to moisture, chemicals, and wear. The glass cloth is composed of glass fibers, while the resin acts as a binder, creating the final structure for the G10 sheets.

The process of creating G10 involves saturating the glass cloth with epoxy resin and then compressing the layers under high pressure and heat. This results in the formation of a dense, hard material known as Garolite. G10 sheets can be found in various thicknesses and colors, making it a versatile choice for various applications.

G10 as a knife handle material

Maintenance and durability

G10 knife handles require minimal maintenance, as they are not prone to rust or oxidation. You can clean your G10 handle with regular soap and water to remove dirt, debris, or stains. Dry the handle thoroughly after cleaning to prevent any potential damage over time. G10 handles are not only durable but also long-lasting, making them a worthwhile investment for your knife collection.

Keep your G10 knife stored away from extreme heat, as it may cause the handle materials to warp or degrade. Additionally, you can protect G10 handles by avoiding heavy impacts or situations that could lead to chips or cracks. With proper care, G10 knives will remain functional and visually appealing for years to come.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Variety and customization

G10 material offers a wide range of options for knife handle customization. You can choose from a variety of colors, grips, and textured finishes, making your knife handle not only functional but also visually appealing.

You will find G10 available in a multitude of colors, allowing you to personalize your knife handle to match your style or intended use. Whether you prefer a bold, vibrant hue or a discreet, subdued shade, there is a G10 color suited to your needs.

In addition to color choices, G10 material provides various grip styles that cater to different preferences and purposes. Some common grip styles include:

- Smooth finish: Offering a sleek and comfortable grip, smooth G10 handles are elegant and ideal for everyday use.

- Textured finish: A textured G10 handle offers increased slip resistance, providing you with a better grip and added control in various conditions.

For further customization, you can get your G10 handle engraved with patterns, logos, or text. Engraving not only adds a personal touch to the knife handle but can also enhance the grip, depending on the design chosen. You can contact us for more information about the various G10 customizations.

Advantages of G10 knife handles

G10 is a high-pressure fiberglass laminate material commonly used in knife handles. It has various benefits that make it a popular choice for a knife handle material.

- Resistant to the surrounding environment: G10 is highly resistant to temperature changes, moisture, and most chemicals, making it suitable for extreme environments.

- Excellent grip: Thanks to its textured surface it allows you to maintain a comfortable hold on the knife, even when wet or sweaty.

- Lightweight: G10 knife handles have a lightweight and slim profile. You can carry a G10 knife comfortably without it being burdensome.

- Customizability: G10 is available in various colors and patterns, allowing you to personalize your knife’s appearance.

- Easy to machine: G10 can be easily shaped and precision-machined. Saving production time for bulk purchases.

Disadvantages of G10 knife handles

While G10 has many advantages, it also has some disadvantages. One potential downside is its cost. G10 handle scales can be more expensive compared to other handle materials, particularly mass-produced plastic alternatives. Another possible drawback is its brittle nature. If subjected to severe impacts, G10 may crack or chip. Additionally, G10 handles may show scratches and wear more easily than other materials.

Under certain circumstances, G10 can be slippery, especially when covered in oil or other lubricants. This might be a concern for those who require maximum grip in specific situations.

G10 vs other knife handle materials

G10 vs other synthetic handle materials

G10 is a high-pressure fiberglass laminate, often used as a knife handle material due to its lightweight nature, durability, and water resistance. When comparing G10 to other synthetic materials like Micarta and carbon fiber, you’ll find differences in weight, durability, and cost.

Micarta

Micarta is a popular choice for knife handles, and like G10, it’s also a laminate material, made from layers of fabric (usually linen or canvas) soaked in phenolic resin. While both G10 and Micarta are durable, G10 tends to have a better grip in wet conditions due to its textured surface. On the other hand, Micarta can offer a more elegant and visually appealing look.

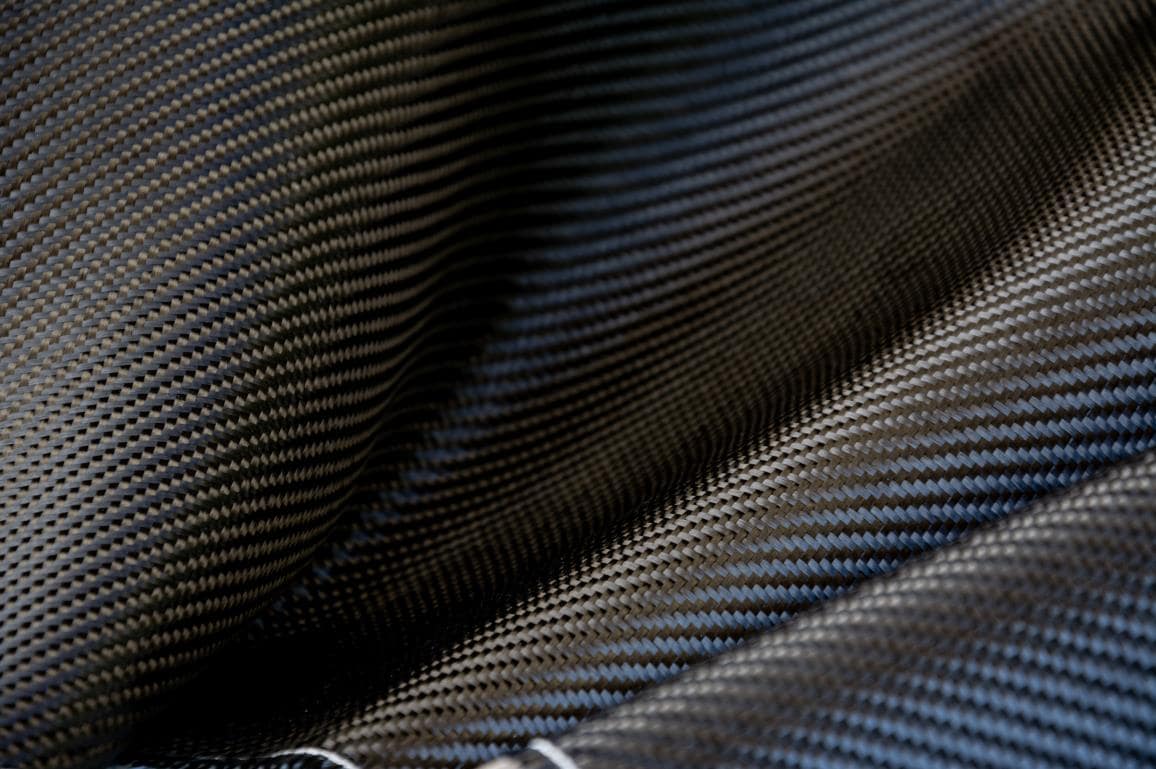

Carbon fiber

Carbon fiber is another synthetic material used for knife handles, known for its lightweight and high-strength properties. However, carbon fiber can be more expensive than G10 and is prone to chipping or cracking under extreme abuse. G10 is a more affordable option without sacrificing strength or durability.

G10 vs natural handle materials

Wood

Wood is a traditional material for knife handles but tends to be more sensitive to moisture and temperature changes. In contrast, G10 is impervious to water and temperature fluctuations, making it a low-maintenance choice. However, wood can offer a unique, beautiful look that many people find appealing.

Bone

Bone is another natural handle material commonly seen in knife-making, with partial to completely finished designs. While bone has a certain aesthetic appeal, it can be more susceptible to cracking and warping compared to G10, which remains stable and durable in varying conditions.

G10 vs metal handle materials

Stainless steel

Stainless steel is a strong and corrosion-resistant material used in knife handles. However, its weight and tendency to become slippery when wet make G10 a more suitable choice, particularly for kitchen knives and outdoor activities.

Aluminum

Aluminum is a lightweight metal used in knife handles, offering a smooth and durable surface. However, G10 still surpasses aluminum in terms of grip, especially in wet conditions, due to its textured surface.

G10 is a versatile and rugged material that stands up well against both synthetic and natural handle materials. Its lightweight nature, durability, and textured surface make it a popular choice in various knife applications, including kitchen knives, tactical knives, and everyday carry tools.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Applications beyond knife handles

G10 material, a popular choice for knife handles, also has numerous applications in other industries due to its unique properties. This high-pressure fiberglass composite demonstrates incredible strength, thermal stability, and electrical insulation properties, making it well-suited for various uses.

Resin-based composites, such as G10, are highly sought after in various industries. Aerospace, automotive, and marine sectors utilize G10 for its robust strength, lightweight nature, and resistance to environmental conditions. For instance, you may find G10 material in the construction of airframes, engine components, and boat hulls, where it provides great impact resistance and structural reinforcement.

Final verdict: is G10 an ideal knife handle material?

Yes, the answer is yes. G10 is an ideal knife handle material for numerous reasons. First and foremost, it is incredibly strong and durable, ensuring that your knife will withstand daily use and general wear and tear. The toughness of G10 makes it an excellent choice for those who subject their knives to rigorous tasks.

One of the significant benefits of a G10 knife handle is its exceptional grip. The textured surface provides enhanced traction, preventing the knife from slipping out of your hand during use. Whether you’re working with wet or dry hands, you can trust that your G10 knife handle will maintain a reliable grip.

Despite its sturdiness and resilience, G10 is surprisingly lightweight. This attribute makes it comfortable to use for extended periods, enabling you to complete tasks efficiently without straining your hands and wrists. Additionally, G10 is a low-maintenance material, which means that you won’t have to worry about it warping, cracking, or succumbing to rust.

It is worth noting that G10 is a material well-recognized among the knife community. That should help you push your decision. There are, of course, alternatives that offer different benefits as a knife handle material. If you are still unsure and want to discuss your options with someone, find us! Through this portal, send us a message, and we’ll get back to you within two business days.