Where Do the Best Japanese Knives Come From?

Japanese blades have earned respect worldwide for centuries. They serve as both cultural treasures and practical kitchen tools. The secret goes beyond just the steel—it’s about where these knives are made. Each Japanese region brings its own traditions, forging methods, and specialties to the craft.

This guide covers:

- The 3 major knife capitals: Sakai, Seki, and Sanjo

- Lesser-known regions producing exceptional blades (Takefu, Tosa, Miki)

- How each region handles forging, sharpening, and handle attachment

- Blade shapes and structures by region

- Leading brands from each area

- How to identify authentic regional knives

Why Japanese Knife Regions Matter

A “Made in Japan” stamp doesn’t tell the whole story.

Many mass-market knives get forged overseas, shipped to Japan for finishing touches, then labeled as Japanese-made. The real value comes from the specific region—where local water sources, steel traditions, and generations of knowledge shape each blade.

Regions like Sakai, Seki, and Sanjo aren’t just production centers. They’re complete ecosystems with their own:

- Steel recipes (Yasuki White #2, SG2 powder steel)

- Forging methods (hand-hammered versus press-forged)

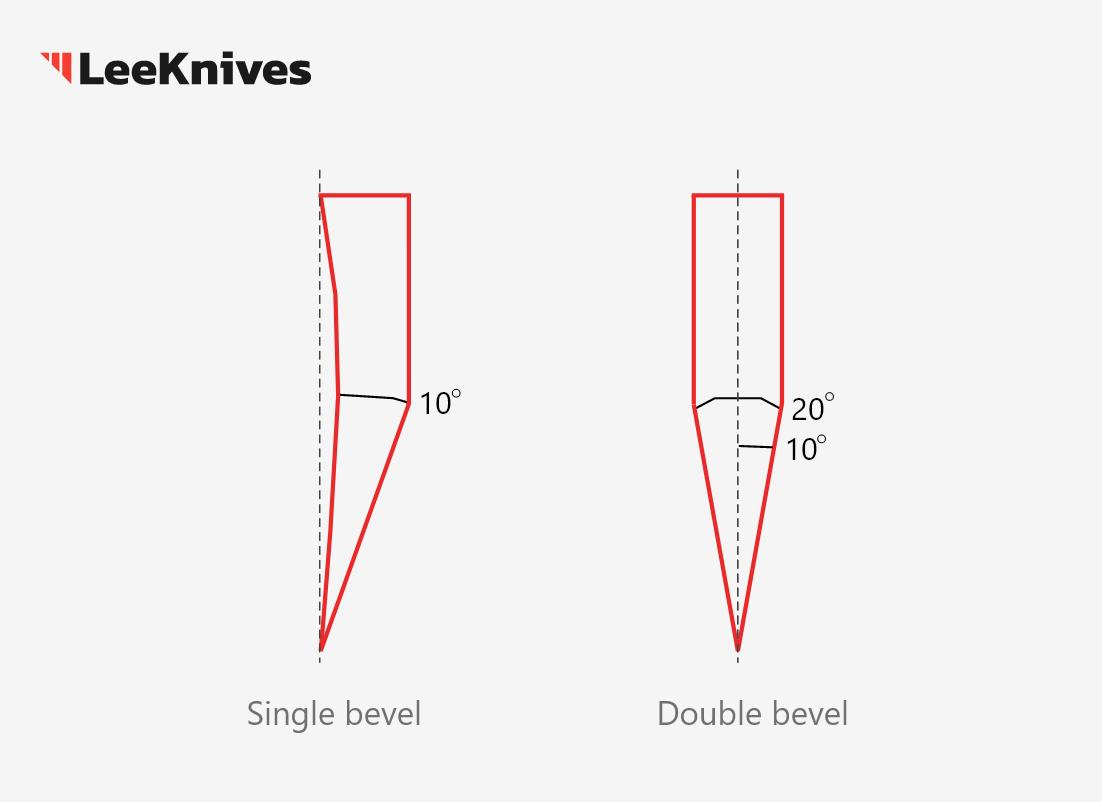

- Blade geometries (single-bevel versus double-bevel)

- Production approaches (specialized artisans versus automated lines)

Look for regional stamps like “堺製 (Sakai-made)” or “関製 (Seki-made)” rather than generic “Japan” markings. Better yet, find the artisan’s signature or workshop seal.

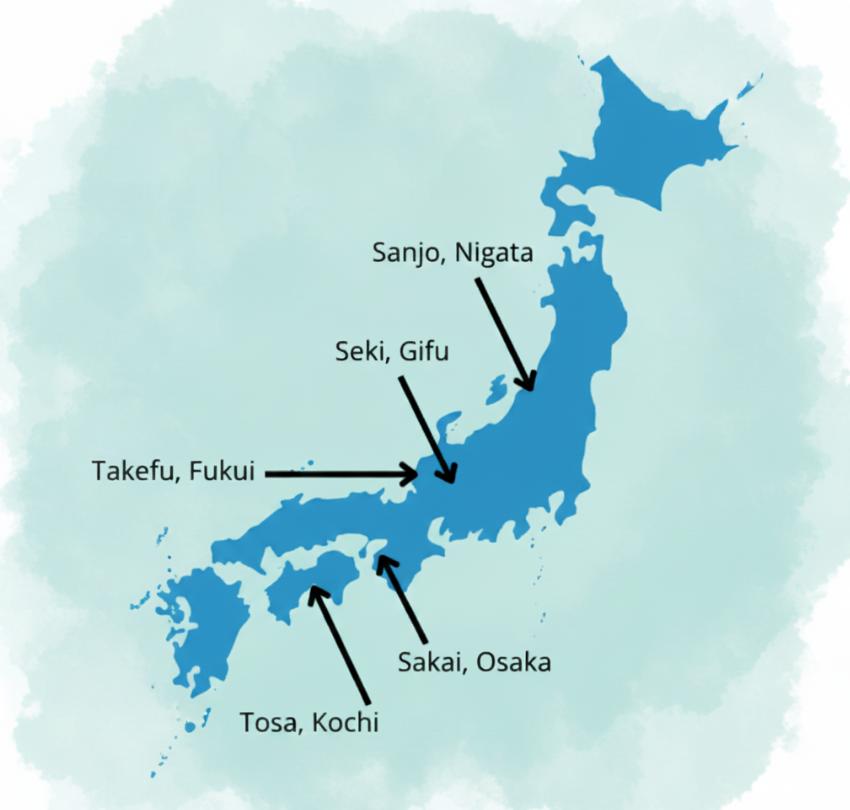

Map of Key Knife Areas in Japan

| Region | Key Features | Specialty Knives | Best For |

| Sakai | Hand-forged, single-bevel, division of labor | Yanagiba, Deba | Professional chefs, Japanese cuisine |

| Seki | Traditional meets modern, mass production | Santoku, Gyuto | Home cooks, Western-style cooking |

| Sanjo | Industrial innovation, integrated metalwork | Multi-purpose, stainless | Design-conscious users |

| Takefu | Artisan cooperative, innovative steel | Damascus, custom knives | Collectors, unique pieces |

| Tosa | Free-forging, rustic style | Black-forged, outdoor | Budget-conscious, rustic style lovers |

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Quick Look at the Top Three: Sakai, Seki, Sanjo

Here is a fast comparison before full details.

| Region | Forging | Sharpening | Handle Attachment | Focus |

| Sakai | Handmade | Handmade | Handmade | Single-bevel, professional use |

| Seki | Machine/Hand | Hand finishing | Semi-automated | Western-style, volume production |

| Sanjo | Handmade | Handmade | Semi-automated | Double-bevel, versatile designs |

Sakai remains the only region where all three production stages stay completely handmade.

Sakai City (Osaka) — The Traditional Knife Capital

History and Heritage

Sakai’s blade-making history stretches back 1,600 years. Blacksmiths first forged tools for Emperor Nintoku’s tomb construction. During the Edo period, Sakai became famous for tobacco-cutting knives. These blades were so sharp they became the model for modern Japanese kitchen knives.

Key statistic: Over 98% of professional Japanese chefs use Sakai-forged knives today, according to the Sakai Tourism Bureau.

The Division of Labor System

Sakai succeeds through specialized division of labor. The forging master (kaji-shi) shapes the blade. The sharpening master (togi-shi) gives it its edge. The handle master (ezuke-shi) ensures perfect balance. Each craftsman dedicates their entire career to mastering one stage. This extreme specialization creates knives with unmatched performance.

Production Process

Sakai maintains strict traditional methods:

- Forging: Hand-hammered over charcoal, folded multiple times.

- Sharpening: A single knife can be honed using a progression of many whetstones.

- Handle attachment: Heated tang insertion with micro-adjustments.

No machines. No shortcuts. Pure craftsmanship.

Benefits for users:

- Sharper initial edge allows cleaner cuts, preserving food cell structure.

- Better flavor retention in delicate ingredients like sashimi.

Leading brands: Sakai Takayuki, Sakai Ichimonji

Blade style: Single-bevel (kataba), perfect for Japanese cuisine and precise cuts.

Identifying Authentic Sakai Knives

Check for these markers:

- “堺極” (Sakai-goku) or “堺打刃物” stamp

- Artisan signature (example: “赤井 高之” for Akai Takayuki)

- Solid wood handle (ho wood, magnolia) with buffalo horn ferrule

- Asymmetrical grind (typically 70/30 or 80/20 right-side bias)

Seki City (Gifu) — Where Tradition Meets Technology

From Samurai Swords to Kitchen Knives

Seki’s sword-making tradition dates to the Kamakura period. Master smith Kanemoto Magoroku forged legendary “unbreakable” blades. Today, Seki ranks alongside Germany’s Solingen and England’s Sheffield as a global knife capital.

The city accounts for 50% of the domestic knife production in Japan, making it Japan’s largest knife production center by volume. It also exports a significant portion of its products, with about 40% of its kitchen knives going to the United States.

Modern Production Methods

Seki successfully blends traditional craftsmanship with modern technology. Many Seki knives combine machine forging for consistency with hand-finishing for critical details. This balance between quality and quantity brings high-performance knives to kitchens worldwide.

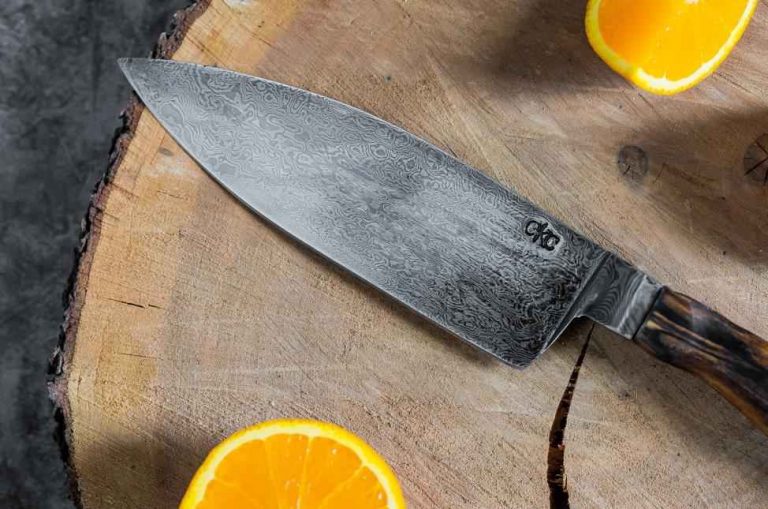

Example of innovation: Shun Premier blades use a VG-MAX steel core and a 68-layer Damascus cladding . The tsuchime (hammered) finish, hand-applied by craftsmen, not only looks beautiful but also reduces drag and keeps food from sticking to the blade .

Production approach:

- Machine forging for consistent results (especially budget lines)

- Hand-finishing for edge geometry and polish

- Semi-automated handle mounting for efficiency and precision

This hybrid model helps Seki dominate the global home kitchen market with high performance at reasonable prices.

User benefits:

- Consistent quality across production runs

- Replacement parts readily available

- Warranty support through established dealer networks

- Left-handed models widely available

Leading brands: Shun, Kai, Masamoto

Blade style: Double-bevel, Western-style chef knives, stainless steel

Seki’s Steel Innovation

Seki blades often feature “特上鋼” (Tokujō-kō)—ultra-pure steel with 95%+ purity. Common alloys include:

- VG-10: Balanced hardness (HRC 60-61), stain-resistant

- SG2 (R2): Powder steel, HRC 63-64, superior edge retention 10

- AUS-10: Budget-friendly yet outperforms Western stainless 10

Smart buying tip: Look for Seki knives that have been certified as a regional brand by the Japan Patent Office as “Seki knives”.

Perfect for home cooks, gift buyers, and left-handed users (many double-bevel options available).

Sanjo & Tsubame (Niigata) — Japan’s Metalworking Heart

From Nails to Knives

Tsubame and Sanjo (often called Tsubame-Sanjo together) form Japan’s metalworking heart. The story began with survival. During the Edo period, frequent floods prevented farming. Local officials invited blacksmiths from Edo to teach nail-making as supplementary income. This humble beginning grew into a world-class metalworking industry.

In 2009, “Echigo Sanjo Uchihamono” received designation as a Japanese Traditional Craft.

Two Cities, Two Approaches

Tsubame-Sanjo’s strength lies in diversity. Tsubame excels at precision metal polishing and processing, creating innovative designs like GLOBAL’s one-piece stainless steel knives. Sanjo maintains more traditional forging methods, producing durable handmade tools.

Success story: GLOBAL knives, designed by Komin Yamada in 1985, revolutionized kitchen knives with their all-stainless construction. No bacteria-harboring gaps between blade and handle.

Production methods:

- Hand-forged blades for premium lines (Tojiro Damascus)

- Press-forged blades for lightweight designs (GLOBAL)

- Hand-sharpened edges on all products

- Semi-automated handle mounting for ergonomic fit

Key advantages:

- Sanitary one-piece construction (GLOBAL)

- 30% lighter than traditional knives

- Dishwasher-safe options available

- Ice-tempering process increases edge retention by 25%

Insider knowledge: Visit during the annual “Tsubame-Sanjo Factory Festival” when many workshops open to the public. It’s a free event designed for visitors to see the manufacturing process firsthand and connect with the artisans behind the products.

Leading brands: Tojiro, Global

Why Choose Sanjo?

- Excellent first Japanese knife—forgiving geometry, works for both hands

- Outstanding Western-Japanese hybrid designs

- Strong online availability and warranty support

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Production Methods Comparison

| Region | Forging | Sharpening | Handle | Characteristics |

| Takefu | Handmade | Handmade | Handmade | Cooperative model, modern steels |

| Tosa | Handmade (rustic) | Handmade | Handmade | Free-forging, rough finish, outdoor focus |

| Miki | Handmade | Handmade | Handmade | Tool-making heritage, pocket knives |

Takefu Knife Village (Fukui) — Innovation Through Cooperation

Takefu traces its roots to 14th-century bladesmith Chiyozuru Kuniyasu. The modern knife village operates as a cooperative where workshops share facilities and knowledge. Senior masters teach younger smiths, preserving tradition while embracing innovation.

Unique model: The Takefu Knife Village is a joint workshop where 13 independent companies work together. This collective effort was crucial for the survival of the traditional craft, allowing small workshops to pool resources and overcome challenges.

Specialties: VG-10 stainless steel development , Damascus-patterned knives.

Brands: Ryusen, Masakage, Katsushige Anryu

Appeal: Popular in Western fine-dining kitchens for Japanese craftsmanship with Western ergonomics.

Tosa (Kochi) — Free-Forging Tradition

Knife-making in Tosa began in the late 16th century when feudal lords welcomed swordsmiths. Tosa practices free forging (jiyu tanzō)—individual smiths create rustic, non-standardized knives. Bold hammer marks and natural finishes define the style. Each knife shows its maker’s personality.

Price advantage: Tosa knives often have a more approachable price point compared to high-end Sakai knives.

Products: Hunting knives, outdoor knives, traditional farm tools.

Users: Adventurers, hunters, outdoor cooking enthusiasts.

Practical benefit: The rough “kurouchi” (black forge) finish is a functional coating that helps prevent rust on carbon steel blades.

Miki (Hyogo) — The Toolmaker’s Heritage

Miki’s forging culture connects to woodworking since the 5th century. By the 16th century, Miki became central to carpentry tool production. The iconic Higonokami pocket knife originated here in 1896 .

Historical fact: Only knives made by the Nagao Kanekoma company can legally use the “Higonokami” name —a trademark protected since 1910 after an influx of low-quality imitations. The “Higonokami Knife Union” once had 40 member companies and over 200 workers in its golden age. Today, Nagao Kanekoma is the only manufacturer remaining .

Specialties: Woodworking planes, chisels, folding knives.

Users: Woodworkers, craftsmen, collectors.

Blade Types by Region

| Blade Structure | Main Regions | Features | Advantages | Limitations |

| Single-Bevel | Sakai, Tosa | Razor-sharp, sushi/sashimi | Precision slicing | Requires skill, fragile |

| Double-Bevel | Sanjo, Seki | Versatile, everyday use | Easy maintenance | Less specialized |

| Honyaki | Sakai | One-piece hardened steel | Ultimate sharpness | Expensive, difficult |

| Kasumi | Sanjo, Takefu | Hard core + soft cladding | Strong, decorative | Quality varies |

| Stamped Stainless | Sanjo, Seki | Machine-pressed | Affordable, consistent | Less character |

Choosing Your Regional Knife

Match your needs to the right region:

- Professional sushi chefs: Sakai is the gold standard for single-bevels, but Seki gyutos make excellent secondary knives.

- Western cuisines & general use: Seki stainless knives shine, with Sanjo hybrids as stylish, durable alternatives.

- Collectors: Takefu Damascus is iconic, alongside Sakai Honyaki and Sanjo Damascus options.

- Outdoor enthusiasts: Tosa’s rustic free-forged knives lead the way, while Miki’s Higonokami serves as a versatile pocket blade.

Final Cut: Why Regional Knowledge Matters

Every Japanese knife tells a regional story: whether it’s Sakai’s artisanal division of labor, Seki’s balance of tradition and scalability, or Tosa’s raw and free spirit. By understanding where a knife comes from, professionals and distributors alike can make smarter purchasing decisions, ensuring authenticity, performance, and heritage.

Partner with Leeknives for Your Knife Business

After learning about Japan’s knife regions, you might wonder how to source these quality blades for your business. That’s where we come in.

At Leeknives.com, we’ve spent 15+ years building relationships with Japanese knife manufacturers. We understand the production standards of Seki, the craftsmanship of Sakai, and the innovation of Sanjo. Our team bridges the gap between Japanese quality and practical business needs.

B2B services we offer:

- OEM Manufacturing: Create Japanese-inspired designs with efficient production

- Private Label: Your brand on proven Japanese knife styles

- Wholesale: Mixed orders from 100 pieces, combining different styles

Why choose Leeknives.com?

- 30-40% cost savings versus direct Japan imports

- Faster lead times through established channels

- Technical support for steel selection and specifications

- Flexible MOQs for testing new markets

Whether you need authentic Japanese knives or Japanese-style designs at better margins, we make sourcing simple. Contact us to discuss how our Japanese knife expertise can strengthen your product line.