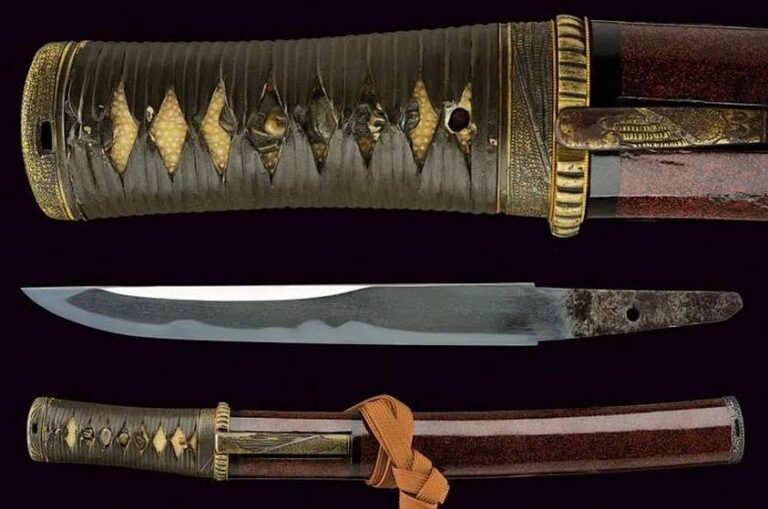

The Japanese kitchen knife, as we know it today, is a direct descendant of the samurai sword. Since ancient times, sword forging techniques have been adopted by knife makers and adjusted to fit more domestic purposes.

With the appearance of modern materials and equipment, some of these techniques became redundant. Yet, some are still practiced and held in high regard, even after hundreds of years.

Online stores selling san mai knives are the perfect example of ancient craftsmanship thriving in the Internet era. Exploring the topic of san bai becomes more than a matter of trivia, but an actual journey into Japanese history.

What is san mai?

At its origin, san mai refers to the forging technique rather than a particular blade type. Since around 1300 A.D., this technique has been used by Japanese bladesmiths to create exceptionally durable blades, including the famous katanas.

In Japanese, “mai” refers to a flat counting unit, such as one sheet in a stack of papers. “San,” as in Santoku, means three.

Hence, san mai translates to “three parts” or “three flat units.” These units refer to layers of steel.

Traditionally, a san mai knife is composed of an inner, hard steel center, called hagane, and two outer layers of softer steel, jigane.

Technically, it is a lamination or forge welding style, which involves heating the steel sheets and hammering them together.

This construction is then ground down from both sides to expose the hard steel edge, which is why san mai knives are always double-beveled.

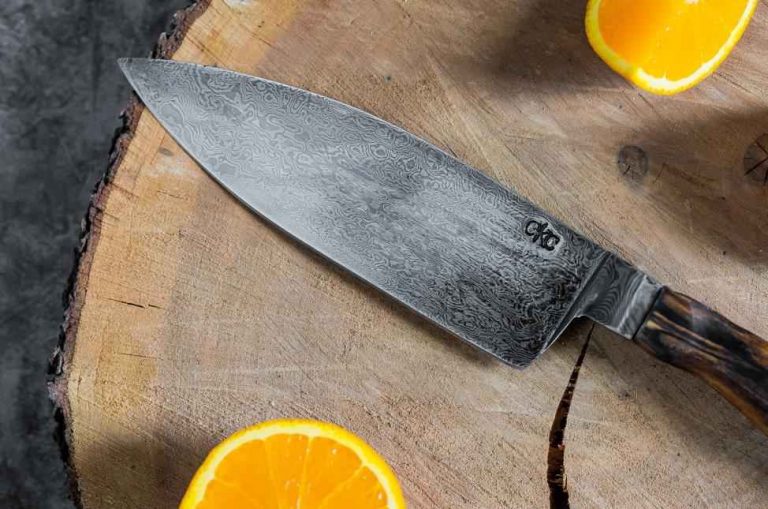

Due to its popularity, the technique has been used outside Japan in modern knife making, often with new types of materials, such as 440C and VG10.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

The history of san mai

It’s important to remember that ancient bladesmiths did not benefit from the array of high-quality, homogenous materials we have today.

Iron ore was processed in special furnaces called tatara to produce blooms – spongy balls of raw material. The bladesmiths would then break these blooms and sort the bits by eye for carbon content.

The bits containing more carbon were used for the inner core, while those low in carbon were reserved for the jacket material. These steel bits were forged to create billets of various materials and repeatedly folded to drive out impurities.

Obviously, this was not an exact science, so san mai and other construction methods were used to create high-quality blades, even though the carbon content could not be evened out.

What is the purpose of the san mai technique?

When looking at modern forging techniques, the san mai method might seem outdated. Yet, san mai tools are still very sought-after and regarded as exceptional quality.

That’s because the hard steel center of the blade provides it with a sharp edge that’s resistant to corrosion and rust, whereas the softer steel layers on the sides make it even more durable.

It’s common for hard steel blades to chip or shatter, so the milder outer layers of a san mai knife give it excellent shock resistance.

Together, the three layers give chefs a “best of both worlds” blade, with an easy-to-sharpen, razor-like edge that can be used daily under extreme conditions.

San mai pros

- Knives have excellent edge retention and are easy to sharpen.

- The outer layer makes them resistant to shocks and unlikely to chip.

- The edge is very resistant to corrosion and rust, making these knives exceptionally durable.

- Many san mai knives feature impressive designs and are sought after for their aspect.

- Blades are created with a reduced cost and conservation of raw materials.

- The san mai technique is suitable for most all-purpose or specialty knives (check our san mai Kiritsuke or Yanagiba samples).

San mai cons

- The stiffer spine makes the blade less flexible than other methods, such as the warikomi technique.

- It’s challenging to evaluate if a bladesmith used the authentic san mai technique or another standard lamination method for a knife.

- The technique requires ample experience, so the manufacturing can become quite costly, despite the lower cost of materials.

San mai steel vs. regular mono steel

While regular, mono steel blades are easier to maintain, they usually ask the user to compromise between durability and sharpness. This is because mono steel blades are not laminated but are created out of a single type of hard steel.

The materials are often scratch resistant and polished into a mirror-like finish, featuring no distinctive patterns.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Other forging techniques

Knife lamination is sorted into various categories depending on how the softer steel encompasses the hard inner core.

Honyaki

Less than 1% of the knives in Japan are Honyaki forged, and many consider these to be the epitome of sophistication. The difference between Honyaki and mono steel blades lies in the method of construction, which was passed down from ancient times.

Honyaki blades are made of a single piece of steel that goes through a two-step quenching process, also known as differential heat quenching.

This process leaves the spine (mune) softer while the edge remains hard and retains its sharpness for a very long time.

Warikomi

The difference between san mai and warikomi blades eludes the eye, as these two techniques are very similar. In Japanese, “warikomi” means interruption, and the Kanji characters can also be used to express splitting or dividing.

The technique implies inserting a hard steel sheet inside softer steel, creating a jacket.

While san mai implies layering the two types of steel, thus leaving the spine exposed, warikomi blades have the spine covered in the softer steel, as well.

Moreover, the inner core does not extend to the entire length of the blade, allowing them to be thinner while still structurally sound.

Ni mai

Ni is the Japanese word for “two,” hence ni mai lamination implies only two layers of steel. Knives crafted with this method are only ground on one side, usually the right, as most single-bevel knives are intended for right-hand users.

If the soft exterior comprises several layers of steel, you’d call the knives ni mai Damascus, as one side of the blade features the well-known pattern.

Should you sell san mai knives in your store?

Since authentic san mai knives usually come at a price, selling these is generally reserved for stores that carry higher-end products. Although a broad customer base prefers san mai knives to standard kitchen tools, you won’t find them in every knife store.

Adding these blades to your store is a commitment to quality, which certainly sends a message. If your brand sells other top-tier products, you’ll probably find san mai knives very lucrative.

Your average home cook might not splurge on a san mai knife, but professional chefs and blade enthusiasts hold these blades in high regard, so finding customers for them shouldn’t be too hard of a task.

Wrap up

Japanese knives are very popular choices across the globe, with the majority of buyers recognizing their superior quality. That’s why many Western countries have adopted Japanese techniques and designs.

These blades are in high demand, and authentic forging techniques such as the san mai give any type of blade an extra layer of credibility.

Without even mentioning the functional advantages of these blades, such as their excellent durability and edge sharpness, you can already conclude that san mai knives are worth their price.

If your clientele is willing to spend hundreds on high-quality, carefully crafted pieces, san mai knives could be an excellent choice for your store.

Luckily, you won’t have to search far and wide for these blades, as the san mai technique is not a mystery for our bladesmiths. You can order wholesale, customizable san mai knives from us and start selling these blades without effort, so let’s have a chat now.