S125V is a high-end stainless steel made by Crucible, using powder metallurgy technology. You may find knives made from S125V steel rarely, and often at very high prices, sometimes hitting the $400 mark. S125V knives are generally harder to manufacture, especially for mass production. Therefore, the high price can be attributed to three factors: the steel is difficult to heat treat, it is expensive itself, and knives are often made individually.

The intricate process of manufacturing S125V steel results in a fine, uniform microstructure that provides you with a blade material capable of achieving and retaining a very sharp edge. The high vanadium content not only enhances the wear resistance but also plays a pivotal role in the formation of hard vanadium carbides, distinguishing it from other stainless steels and contributing to its superior cutting performance.

Should you invest in S125V steel at this moment? How does it compare with its sister steels like S90V and S110V? Find out in this article.

Overview of S125V steel

S125V steel is manufactured by Crucible Industries as a CPM stainless tool steel. If you are seeking a steel with exceptional wear resistance and edge retention, S125V is exceptional.

It is a high-performance steel that excels in all aspects of knife steel, except that it’s difficult to sharpen and manufacture. S125V steel is almost exclusively crafted by private knifemakers for custom orders at a high price.

More details on its specific characteristics will be provided. Additionally, we will discuss how it compares to other powder metallurgy steels, and explore its comparison with similar premium steels.

Chemical composition of S125V steel

CPM S125V is a high alloy stainless tool steel. Its chemical composition is engineered to offer an exceptional mix of wear resistance and toughness. This specialty steel is formulated by Crucible Industries using their proprietary Crucible Particle Metallurgy (CPM) process.

- Carbon (C): 3.25%

- Chromium (Cr): 14.00%

- Molybdenum (Mo): 2.50%

- Tungsten (W): 0.40%

- Vanadium (V): 12.00%

- Manganese (Mn): 0.50%

- Silicon (Si): 0.90%

- Phosphorus (P): 0.03%

- Sulfur (S): 0.03%

Vanadium is a key component of this steel, responsible for balancing its toughness, edge retention, and hardness.

Due to its unique combination of elements, S125V steel is well-suited for applications requiring extreme wear resistance and durability, such as high-end cutting tools and knives. However, it’s important to note that working and sharpening S125V steel may require more effort due to its hardness.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Physical characteristics

In a nutshell, S125V’s performance as a knife steel is excellent overall, with the only drawback being its difficulty to sharpen. Its exceptional hardness and excellent wear resistance make it a great fit for various knife applications.

Hardness and edge retention

S125V boasts superb edge retention and hardness, typically averaging around 65 on the Rockwell hardness scale under proper heat treatment. This extreme hardness significantly contributes to superior edge retention. Knives made from S125V will maintain their sharpness for prolonged periods without the need for frequent sharpening.

Wear resistance

S125V steel can compete as one of the strongest steels in terms of wear resistance, thanks to its high hardness and the presence of vanadium carbides. Knives made from S125V steel will effectively withstand abrasive and adhesive wear, ensuring a longer service life.

Corrosion resistance

While corrosion resistance is not the primary feature of S125V steel, it displays a fair resistance to rust and corrosion compared to other high-hardness steels. However, it’s crucial to maintain proper care and possibly add surface treatments to enhance this property.

Sharpening S125V steel is notably more challenging than with average steel. Diamond sharpeners are necessary to effectively address the vanadium content. It demands patience and skill, yet the infrequency of sharpening tasks compensates for the effort.

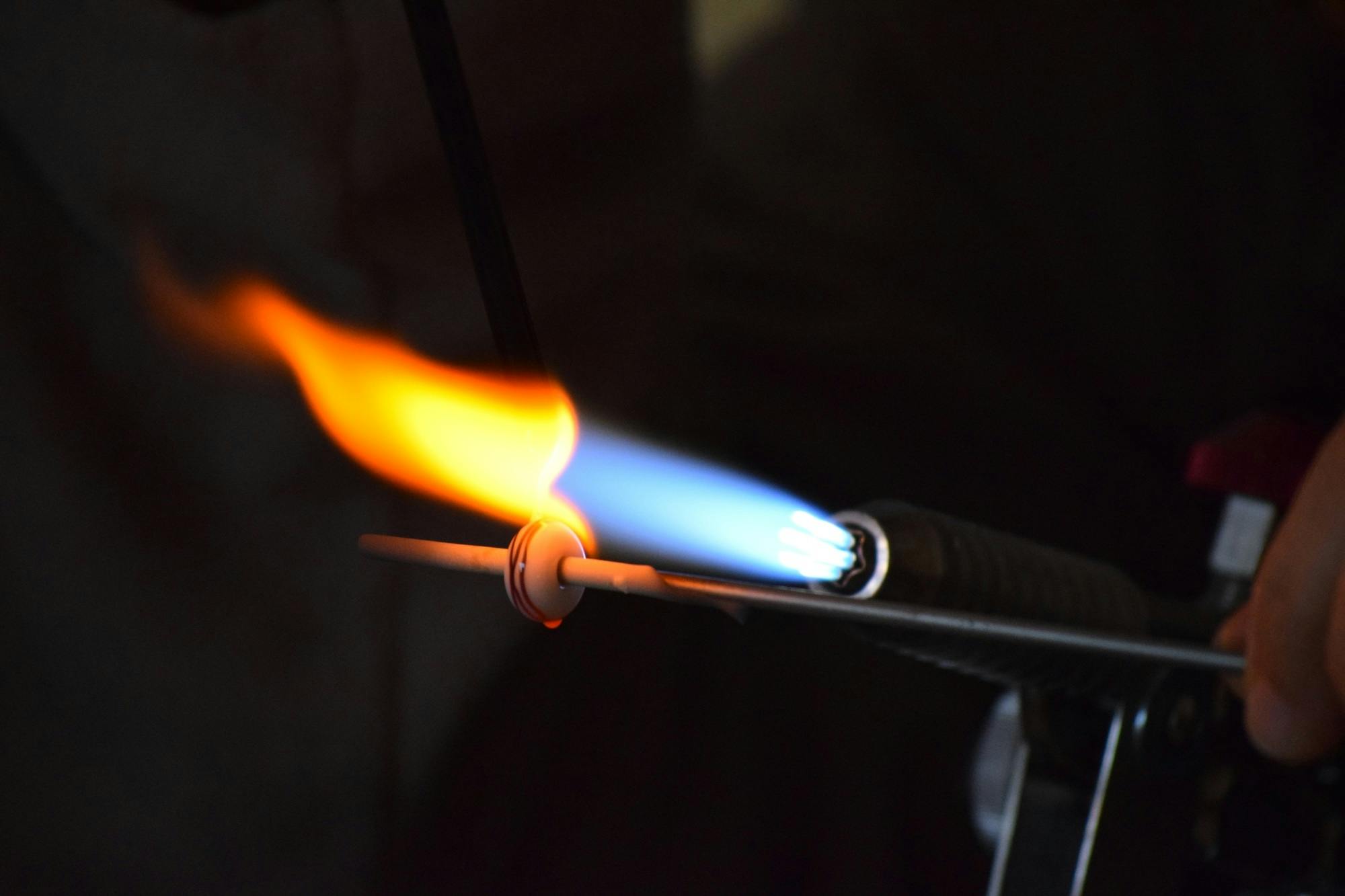

Manufacturing process

In the context of S125V steel, the manufacturing process is a critical factor that determines the final properties of the material. You will find that this process involves advanced techniques to ensure the steel’s superior performance.

S125V vs. other steels

S125V, S90V, and S110V

When comparing S90V, S110V, and S125V, it’s evident that while there are differences among them, these discrepancies are marginal. As a wholesaler or business considering an investment in one of these steels, the choice between the three may not significantly impact performance. Instead, factors such as prices and workability become more crucial considerations.

Each steel offers exceptional characteristics, with S90V known for its superb edge retention and corrosion resistance, S110V prized for its extreme wear resistance and toughness, and S125V valued for its outstanding hardness and edge retention. However, the subtle variations in these properties may not significantly affect the end performance of the products. Therefore, when making a decision, it’s essential to prioritize factors such as cost-effectiveness and ease of manufacturing, as these aspects can have a more substantial impact on overall profitability and success.

M390

When comparing M390 and S125V, both are high-performance stainless steels renowned for their exceptional qualities in the realm of knife making. M390, developed by Bohler-Uddeholm, and S125V, produced by Crucible Industries, excel in different areas.

M390 is celebrated for its impressive corrosion resistance, excellent edge retention, and ease of sharpening. Its composition, featuring high levels of chromium, vanadium, and molybdenum, contributes to its outstanding durability and resistance to wear. On the other hand, S125V boasts exceptional hardness and edge retention, making it particularly well-suited for applications requiring extreme wear resistance. With its high vanadium content and proprietary particle metallurgy process, S125V offers unparalleled toughness and edge stability.

M390 may be preferred for its corrosion resistance and ease of maintenance, while S125V shines in applications demanding the utmost in wear resistance and edge retention.

14C28N

14C28N, developed by Sandvik, is recognized for its excellent balance of edge retention, corrosion resistance, and ease of sharpening. It’s a popular choice for mid-range and budget-friendly knives. When considering these two steels, the choice often depends on the specific requirements of the knife and the preferences of the user. 14C28N may be preferred for its affordability, ease of maintenance, and versatility, making it suitable for a wide range of users and applications. On the other hand, S125V is favored by those who prioritize top-tier performance and are willing to invest in a premium material for specialized tasks that demand the highest level of performance and durability.

Remember, the more wear-resistant a steel is, the more challenging it can be to sharpen. Your S125V knife will require patience and proficiency to sharpen once it eventually dulls. Despite this, the longevity of S125V’s sharpness makes it a compelling choice if you prioritize edge retention and wear resistance above other attributes.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Should you invest in S125V steel?

In general, most people would advise against investing in S125V steel as a material for knife making. Unless you have both the financial resources and time to experiment with this steel and are confident that your customers are willing to pay the high prices associated with it.

The steep price tag and extremely challenging forging process present significant obstacles when working with this steel. Unless there is a clear demand from customers actively seeking knives made with S125V, mass-producing knives with this steel may not be a wise decision.

It’s advisable to start with safer options like D2 or 14C28N. Which offer more flexibility in terms of pricing and are favored by a wider range of customers. If you’re ready to kickstart your own knife-selling business, consider reaching out to LeeKnives! As an OEM knife manufacturer, we not only offer wholesale options but also services such as private labeling and dropshipping. Get in touch with our sales representative today to request a quote and take the first step towards your entrepreneurial journey.