Vanadis 4E is a high-performance material used for making cutting tools. Developed by Uddeholm, it’s produced using powder metallurgy, a process that ensures the steel has a very fine carbide distribution. This fine microstructure means you get a steel that’s tough and can hold a sharp edge well, which is super important for precise work. Plus, it’s resistant to chipping, which is a big deal for heavy-duty use. However, it’s not the best when it comes to rust resistance.

While Vanadis 4E steel might not shine brightest in terms of corrosion resistance, its other qualities make up for it, making it a solid choice if rust isn’t your top worry. It’s likely the top pick for its price. It’s not overly fancy or premium, but it’s highly sought after for its balanced properties. For a detailed breakdown of this steel, dive deeper into the article.

Overview of Vanadis 4E steel

Vanadis 4E is a powder metallurgy steel produced by Uddeholm, a renowned steel alloy company in Sweden. Its full name is Vanadis 4 Extra. The Vanadis line includes various other variations such as Vanadis 8, Vanadis 60, etc. The steel is mostly known for its superior toughness and edge retention. It’s pertinent to note that the powder metallurgy process is vital to the performance of Vanadis 4E. Uddeholm’s use of this method ensures a controlled distribution of carbides in the steel, contributing to its impressive wear resistance and ability to retain an edge.

Chemical composition

When you’re exploring the specifics of Vanadis 4E steel, one critical aspect to consider is its chemical makeup. This high-performance powder metallurgy tool steel is crafted by Uddeholm and known for its balanced combination of durability and hardness, which is largely due to its unique chemical composition.

- Carbon (C): 1.40%

- Chromium (Cr): 4.70%

- Molybdenum (Mo): 3.50%

- Vanadium (V): 3.70%

- Manganese (Mn): 0.40%

- Silicon (Si): 0.40%

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Vanadis 4E performance

Hardness and edge retention

Vanadis 4E steel, also known as Vanadis 4 Extra, is renowned for its high hardness typically above 62 HRC after heat treatment, which ensures excellent edge retention. This powder metallurgy tool steel is designed to retain a sharp edge even through intense usage, making it a top choice for high-performance cutting tools.

Toughness

Despite its high hardness, Vanadis 4E steel does not compromise on toughness. Its impressive ductility allows it to withstand high levels of stress and shock without chipping, making it highly reliable for demanding applications.

Corrosion resistance

While Vanadis 4E steel offers moderate corrosion resistance, it’s not as resistant as some stainless steels. You may need to maintain the steel with proper care to prevent rust, especially if it’s frequently exposed to moisture or corrosive substances.

You’ll find that sharpening Vanadis 4E steel is straightforward, given its uniform microstructure. However, due to its hardness, a more abrasive sharpening medium, such as a diamond or ceramic stone, may be required to effectively hone the cutting edge.

Manufacturing process

In the production of Vanadis 4E steel, your understanding of the sophisticated Powder Metallurgy (PM) technique is pivotal. This process is critical for achieving the material’s unique properties.

Powder metallurgy techniques

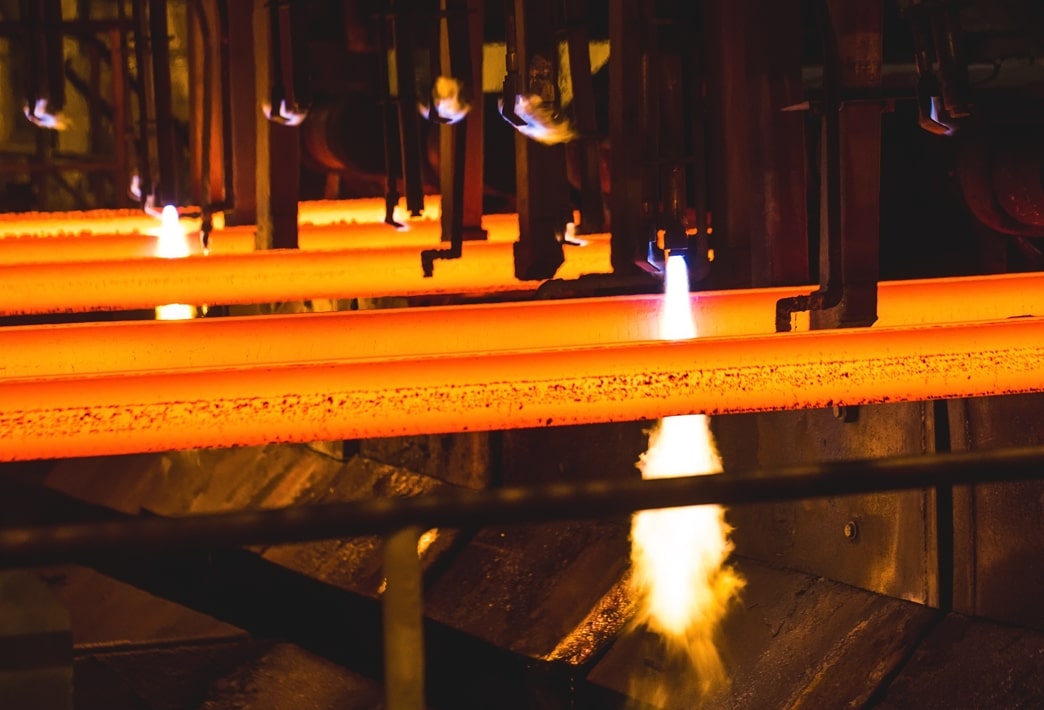

Powder Metallurgy is an advanced manufacturing process used to produce Vanadis 4E steel. Initially, high-quality raw materials are selected and melted in an advanced furnace which ensures purity and consistency. Here’s a step-by-step breakdown:

- Melting: The raw materials, including iron, carbon, and other alloying elements, are melted in an electric arc furnace.

- Atomization: The molten steel is then atomized using high-pressure jets of gas or water, creating fine steel powder.

- Blending: The powdered steel is blended to achieve a homogeneous mix of the necessary alloying components.

- Compacting: Under controlled temperatures and pressures, the powder mix is compacted into a dense form.

- Sintering: The compacted steel is heated to a temperature that allows the particles to bond without melting fully – this process is known as sintering.

- Heat treatment: Subsequent heat treatment processes enhance the steel’s mechanical properties by altering its microstructure.

Through this PM process, Vanadis 4E steel is endowed with its exceptional wear resistance and toughness. Your tools crafted from this powder metallurgical cold work tool steel offer improved performance due to the even distribution of carbides and clean microstructure achieved through PM.

Vanadis 4E vs. other steel

When evaluating the performance of Vanadis 4 Extra steel, it’s important to consider how it stacks up against other popular alloys in the industry. You’ll find that each type of steel has distinct characteristics tailored for specific uses.

M390

M390 and Vanadis 4E differ in their chemical compositions and properties. These high-performance tool steels have distinct strengths. M390 stands out for its excellent corrosion resistance and edge retention, making it ideal for applications requiring durability. On the flip side, Vanadis 4E excels in toughness and edge retention, making it a top choice for tasks demanding strength and resilience. Despite their dissimilarities, both steels deliver impressive performance in their respective domains. When deciding between them, it’s crucial to consider your specific needs and choose the steel that aligns best with your requirements.

CPM M4

Vanadis 4E and CPM M4 are both high alloy tool steel. They share almost identical chemical compositions. Consequently, their performance is very similar. According to KnifeSteelNerds, if treated under the same heat conditions, CPM M4 edges out slightly in retention but lags behind in toughness compared to Vanadis 4E. Both steels have rather poor rust resistance. Ultimately, your decision between the two boils down to which steel is more readily available in your area.

Vanadis 8

Vanadis 4E and Vanadis 8 are both high-performance tool steels developed by Uddeholm, but they have distinct characteristics that set them apart. Vanadis 4E is known for its fine carbide distribution, providing excellent toughness and edge retention. It’s particularly suited for applications where precision and durability are paramount. On the other hand, Vanadis 8 offers superior wear resistance and edge stability, making it ideal for tasks involving heavy cutting and abrasive materials.

Elmax

Vanadis 4E and Elmax are both high-quality tool steels with distinct advantages. Vanadis 4E is known for its exceptional toughness, while Elmax boasts similar edge retention along with superior corrosion resistance. The choice between them depends on the specific needs of the application. If toughness is a priority, Vanadis 4E is a solid choice, while Elmax is preferred for its excellent corrosion resistance and comparable edge retention.

CPM CruWear

CruWear and Vanadis 4E are two high-performance tool steels that share many similarities. Both are recognized for their exceptional toughness and edge retention, making them ideal choices for demanding applications where durability is key. While they have slight differences in their chemical compositions and heat treatment requirements, their overall performance is quite comparable. The decision between them may come down to factors such as availability and specific requirements of the application.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Choosing Vanadis 4E steel as your next investment

Vanadis 4E stands out as a popular and excellent choice. Renowned for its remarkable toughness and durability, it competes with some of the hardest, toughest steels available. However, it does fall short in rust resistance. If availability is a concern, alternatives like M4 and CruWear offer similar performance and are equally commendable choices. Regardless of the steel you select, ensuring you source from a reliable supplier and manufacturer is crucial. At LeeKnives, we boast extensive experience in working with, heat treating, and assembling knives made from various steels. Contact us today to discover how we can fulfill your knife needs!