If you’re selling knives, both knife sharpeners (electric or manual) and whetstones are recommended items to have in your stock offering.

What are these knife care products specifically? How do they compare and how are they different? In terms of performance, is one better than the other? Which should you be recommending to your customers?

As a quick answer: both sharpeners and whetstones have their place in the knife care industry, but they’ll each suit a different segment of the market.

Why is knife sharpening important?

Knife sharpening is an essential activity for the knife owner because any knife will have its blade edge dulled through use.

Some knives will lose their sharp edge quicker than others based on a wide variety of factors, but the fact remains that every single knife regardless of origin or quality will need sharpening.

Knife sharpening is important because:

- A sharp knife is safe to use – a dull knife can slip and cause cuts

- Knives cost money and sharpening a knife is protecting that investment and giving longevity to the product

- Sharp knives enhance productivity – food prep can be done faster, easier and with less labor intensity

- A sharp knife allows for precision cutting, this is important to eliminate food wastage and allow for detail work like garnishes

- A damaged or chipped blade can harbor bacteria and tiny particles of metal can get into food

What is a knife sharpener?

A knife sharpener is a tool used to reform and abrade the edges of a knife blade. Knife sharpeners can be electrically powered or used manually.

Any knife sharpener operates by removing trace amounts of material from the knife blade in order to achieve the desired edge.

Let’s look more closely at electric and manual knife sharpeners.

Electric knife sharpener

Small appliance with slots featuring abrasive surfaces that automatically rotate against the knife blade surface.

It was used by the user turning on the machine and inserts the knife blade into the slot(s) provided, pulling the blade through and between the moving sharpening disks.

They electric knife sharpener requires no prior sharpening skills from the user, is quick to use and has very low maintenance. But it’s also difficult to control the sharpening angle and can damage your knife blade.

Manual knife sharpener

Small hand-held or surface fixed implement with slots featuring angled abrasive surfaces. Similar to electric sharpener, the user either holds or positions the sharpener and pulls the knife blade through the sharpening slot(s) provided.

With a manual sharpener, you are able to take more control with the sharpening angle. It’s a portable option since it doesn’t need electric to function, but may need some practices to get used to.

What is a whetstone?

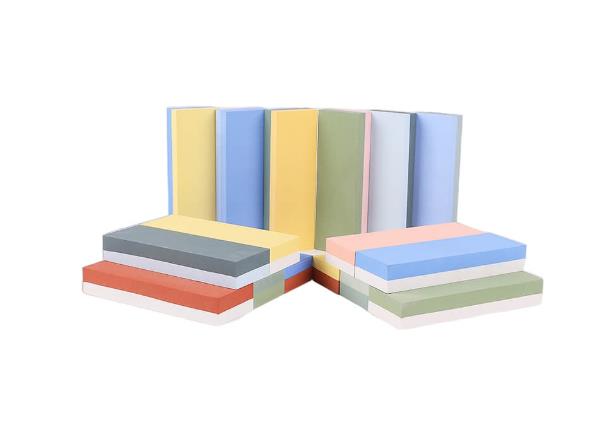

Whetstones are either natural or synthetic sharpening surfaces for knives. Their abrasive texture removes material from a knife blade, making it sharper.

Whetstones can be categorized by their lubricant substance or the material it was made of. Whetstones can also vary in grit (roughness) – fine, medium or coarse. Some whetstones offer more than one grit type on a single stone.

How to use a whetstone

- Select the right whetstone and grit level for the knife. Coarse grit (around 220 grit) for repairing blade chips ONLY; around 1 000 grit (medium) for standard sharpening; and lastly a grit surface around 4 000 (high) for polishing.

- Secure the stone firmly to the work surface.

- Add the recommended lubricating fluid.

- Determine the correct sharpening angle.

- Proceed with sharpening.

- Clean and store the whetstone or whetstone kit properly according to the manufacturer’s instructions.

Whetstones: what you need to know

- Different types of knife blade will require a specific type of whetstone for best quality sharpening.

- Recommend a whetstone or other sharpening product that suits the material/shape/hardness etc. of the blade to be sharpened.

- Depending on the bevel edge and blade design, knives have ranging optimal sharpening angles. The accepted sharpening angle for a regular chef’s knife for example is 20 degrees but this doesn’t apply to every kind of knife.

- Customers should be advised to follow the manufacturer’s directions for the whetstone closely and be advised on the sharpening angle best for the knife they’re purchasing.

Buy Wholesale Sharpening Tools and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Knife sharpener vs whetstone: how they compare

Both knife sharpeners and whetstones sell and have a defined market of buyers, have no doubt about that. Although they achieve the same end, they’re different products and are therefore suited to different buyers.

Ease of use

Knife sharpeners whether manual or electric are easy for anyone to use provided the usage instructions are consulted and followed.

Whetstones

Using a whetstone isn’t a matter of relying on a tool to essentially do the job for you, using whetstones for sharpening is a process that requires skill, patience, muscle memory and some understanding of blade design and knife steels.

Whetstone sharpening is a process that true knife enthusiasts really enjoy and choose to do instead of using sharpeners.

What does this tell us about our clientele?

Your ‘average Joe’ customer or home cook without a lot of knife knowledge is going to be more suited to knife sharpeners and will find them much easier and more pleasant to use regularly.

The knife fundi or bladesmith will need and indeed expect you to have a competent range of whetstones available because they want to manually do their own sharpening and tailor their sharpening stone routine to their particular knife needs.

Maintenance

Manual sharpeners need almost no maintenance besides dusting off after use and electric sharpeners will only need professional or skilled intervention in the case of a mechanical or electrical fault.

Whetstones

Whetstones do need maintenance in terms of cleaning, maintaining and storing the whetstone kit properly and some whetstones will need levelling as they can wear down after use.

What does this tell us about our clientele?

A product that requires intervention and a maintenance routine on the part of the buyer is best suited to serious hobbyists and enthusiasts as opposed to your everyday user because time, effort and prior knowledge are required.

Sharpeners sell because they work and require little skill or time investment. A knife snob would tell you that the level of sharpening control that you can achieve with a whetstone isn’t there, but sharpeners do the job, that’s indisputable.

Whetstones

For the person that takes knives very seriously, a whetstone allows for a more intensive, tactile and immersive sharpening experience and there is credence to the opinion that the quality of the sharpening achieved is better than that from sharpeners.

What does this tell us about our clientele?

Your average customer will likely not understand or be concerned about nuances in sharpening quality. They just want their knife sharpened quickly and easily, end of story.

The hobbyist or blade expert will know about and be invested in things like blade ergonomics, knife steel specs, and sharpening methodologies. This customer will want and demands a whetstone system that fulfils their need for a ‘specialist’ product.

Whetstones vs sharpeners – the verdict

The wise retailer will offer both sharpeners and whetstones so that you’re servicing every segment of the market with a sharpening solution that will suit them.

Market competitiveness and pricing

Both sharpeners and whetstones have a devoted clientele and knife sharpening is necessary, everybody who buys a knife will eventually have to sharpen it for that knife to perform. That’s very good news for the knife products retailer!

In terms of pricing, knife sharpeners and whetstones or whetstone kits are accessible at a range of price points from affordable to costly. We recommend that retailers carry a stock that offers a range of pricing levels.

Buy Wholesale Sharpening Tools and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Honing rods – how do they fit in?

Honing rods or honing steels are another knife owner’s essential, particularly for serrated knives, and they work by realigning the blade of a knife and pushing it back to ‘true center’ for optimal balance in the user’s hand.

Honing is an activity that goes hand in hand with good sharpening practice for best knife performance, so by having honing rods in stock you’re offering a holistic, full service knife care supply.

In conclusion

LeeKnives has enjoyed preparing this overview of knife sharpening products for your information.

We hope that our product guides and consumer advice have both informed and inspired you to knife sales success!

Please feel free to contact us anytime for retail guidance, product information, or a quick and easy quote.