Selling cutting boards is a natural step for knife shops looking to expand their line of products. It’s the first item that goes with kitchen knives.

When choosing the cutting boards to sell, wood is at the top of the list – but like knife steel, not all are equal. While the wood choice determines many features of the product, the grain also plays a significant role.

In this article, we’ll cover the wood grains for managers and owners of knife shops. Read through the rest to find out the main traits of each.

What is wood grain?

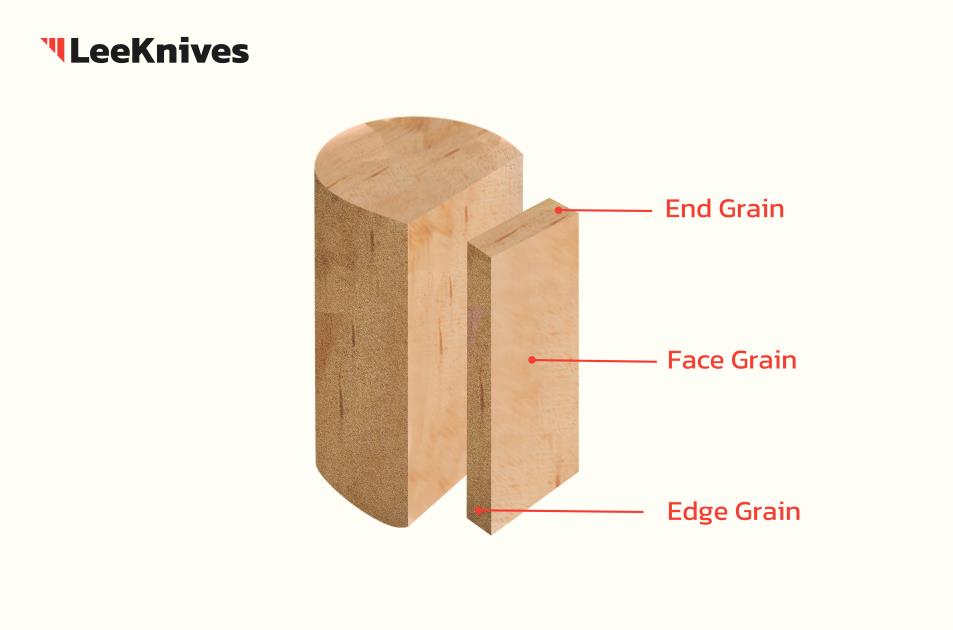

The wood grain refers to the surface of the wood. Every lumber has three types of grain determined by the arrangement of the wood fibers.

These are edge grain, face grain, and end grain. The fibers run horizontally in edge and face grain wood. The end grain separates itself from the two with vertically stacked wood fibers.

In a piece of lumber, the edge grain is the side, the face grain is the widest surface, and the end grain is where it comes to an end. It’s pretty straightforward to explain, but when these three different wood grains make a cutting board, they present varying traits.

Edge grain

The edge grain is the side of the lumber – often the place woodworkers take into account for measuring the thickness.

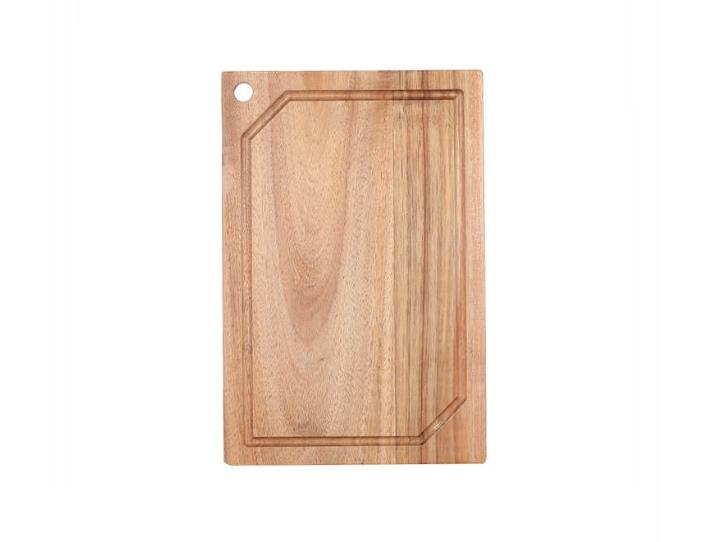

A cutting board made from edge grain wood is constructed by cutting the lumber into long strips and gluing them together. If a cutting board’s surface shows not-so-thick strips, it’s an edge grain cutting board.

Features of edge grain cutting boards

The edge grain is one of the most popular choices for cutting boards. The highlight of edge grain cutting boards is their ability to resist water.

The long streaks of densely packed wood fibers make it difficult for moisture to penetrate. By the time liquids have a chance to go deep within the board, they mostly evaporate. This protects edge grain cutting boards against warps and cracks.

The edge grain also produces a lightweight cutting board. They don’t have to be thick for sufficient durability. An inch and a half thickness is optimal for an edge grain cutting board to withstand heavy chopping.

These make edge grain cutting boards popular, but they tend to dull knives quickly, especially if made from hardwoods, like maple and cherry. When making complete contact with the board, the horizontally running fibers can damage the cutting edge.

This downside, however, isn’t a problem for most cooks. The benefits of edge grain cutting boards outweigh the drawbacks, making them a fitting product choice for average users. A home cook looking for something simple, durable, and affordable will find edge grain cutting boards satisfying.

Pros

- Great water resistance.

- Low-maintenance.

- Affordable.

Cons

- Tends to dull knives.

- The direction of the wood fibers means the edge will cut through them, showing more scratches on the surface.

Buy Wholesale Cutting Boards and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Face grain

The face grain is the widest part of the lumber. It often shows the growth rings that add to the aesthetic appeal. Since the surface area of face grain wood is large, it takes fewer pieces to make a cutting board. They also don’t need to be as thick, making them lightweight.

These make face grain cutting boards more affordable to manufacture than others.

Features of face grain cutting boards

The face grain cutting boards resist moisture quite well but tend to soak more than edge grain. This is because face grain is softer than edge grain. Still, it doesn’t soak liquids as much as the end grain. Therefore, it doesn’t require the user to upkeep their cutting board as often.

Face grain makes a lightweight product thanks to larger pieces of wood coming together to form a cutting board. This also means fewer stages to manufacturing a face grain cutting board, further dropping its cost.

A lightweight and affordable cutting board surely sounds good. However, the face grain cutting boards don’t have the best reputation, especially among chefs. Most cooks choose them for their beauty rather than the practical qualities they get.

Similar to edge grain cutting boards, they show knife marks but to a higher degree. The soft surface can’t resist heavy chopping, and the blades made from hard steel will slash through the fibers. This is enough to lower expectations of the durability shoppers get from face grain cutting boards.

Pros

- Adequate water resistance.

- Lightweight and affordable.

- Makes a striking cutting board, showing the wood fibers and the tree’s growth rings.

Cons

- Not as durable as others.

- Shows scratches and other knife marks, making it unfit for heavy chopping.

End grain

The end grain is the end of the lumber. The woodworker cuts the lumber into square-like blocks and glues them together to build a cutting board. This multi-step process requires more wood, making end grain cutting boards more expensive than others.

The more wood there is, the heavier the end-product. This can be a critical consideration for some users, especially home cooks. An end grain cutting board is most appropriate as a stationary cutting surface with a dedicated place in the kitchen. No wonder butcher’s blocks are almost always made from the end grain of the wood.

Features of end grain cutting boards

As mentioned at the beginning, the end grain has fibers that run vertically. This trait gives end grain cutting boards a distinct feature your customers won’t find in the edge or face grain alternatives.

When the knife contacts the board, the edge will go between the fibers. It will give the cutting edge a soft stop, not affecting its sharpness. This feature makes end grain cutting boards by far the best surface to chop for professionals.

They also make durable cutting boards that can potentially outlive kitchen knives.

However, these benefits come with a few downsides. Because there’s some space between the fibers, end grain cutting boards soak more liquids than others. Because of this, they are prone to stubborn stains and unwanted smells.

A regular care routine is a must with end grain cutting boards, which most chefs and serious cooks don’t mind. If caring is overlooked, though, end grain cutting boards can warp, crack, and lose their appearance.

Washing end grain cutting boards thoroughly with hot soapy water for sanitizing and coating the surface with mineral oil is a must. Knife shops selling end grain cutting boards should advise their customers about these maintenance requirements. Otherwise, their second visit to the store won’t be for another purchase.

Pros

- They are by far the gentlest on knives.

- Makes the most durable cutting board.

Cons

- Can’t resist moisture as good as edge and face grain cutting boards.

- Tend to be heavy and pricey.

Edge vs. end vs. face grain

So far, we’ve discussed the individual characteristics of edge, end, and face grain cutting boards. Here is how they compare.

Water resistance

The cutting board’s surface keeping moisture away is vital for preventing warps. Edge and face grain do this better than end grain due to the direction fibers run and density. The side of the lumber is densely packed, not giving much room for moisture to penetrate.

Yet, the soft surface of face grain cutting boards can soak liquids similar to end grain. That said, edge grain is best at resisting damages caused by water and moisture.

Durability

While warping and twisting can be a problem with wood cutting boards, it isn’t a big concern with some upkeep. When compared, the end grain cutting boards are the most durable assuming they all get enough care.

End grain cutting boards are long-lasting because they can take a heavy beating without permanent damage to the surface. The vertically standing wood fibers have a self-healing attribute. They close up when the cook lifts the knife and tighten up over time – explaining why end grain cutting boards don’t show as many scratches.

The edge grain lasts longer than face grain cutting boards, but the use case also matters. A cook using a face grain cutting board for slicing will get more service than another using an edge grain cutting board for heavy chopping.

Knife sharpness

As we’ve pointed out a couple of times in this article, end grain cutting boards are best for the sharpness of knives. A chef using a kitchen knife with great edge retention may not notice this immediately, but a home cook using an average knife will.

Between edge and face grain cutting boards, the former is gentler on the cutting edge as it’s softer.

Price

Due to how they are built, face grain makes the least expensive cutting board. It requires fewer pieces and adhesives. There are even face grain cutting boards from a single piece of wood.

Although edge grain cutting boards require more from the manufacturer, they aren’t too costly either. The case is different with end grain cutting boards. It requires much smaller, individual pieces of wood that are thicker. End grain cutting boards take more labor, adhesives, and wood.

All these make them more expensive to manufacture. Additionally, the shipping costs are higher with end grain cutting boards as they are heavier.

Other things to consider

- Weight: Some cooks prefer a lightweight cutting board they can move around in the kitchen; some want something fixed. If selling a cutting board to the first customer type, a big end grain cutting board won’t give the best time.

- Aesthetics: A cutting board can be more than just a surface to cut ingredients. Many cooks use them as display plates, like presenting canapés.

- Maintenance: End grain cutting boards demand more supervision. This isn’t an issue for professionals, but note that most home cooks look for something carefree.

Which one should you sell in your store?

There isn’t a best or one-size-fits-all with wood cutting boards. Cooks with various needs will look for different features in the surface they cut ingredients.

If you’re looking to provide your customers with an affordable yet long-lasting cutting board, edge grain made from hardwoods is the way to go. They will keep moisture away, won’t show an excessive amount of scratches, and last for years with some care.

Buy Wholesale Cutting Boards and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

The qualities an average user will find in face grain cutting boards are also fair. They will need to be replaced faster than the edge and end grain cutting boards, but at least the cost won’t bat an eye.

On the other hand, end grain is the most durable and efficient – just not for everyone. They tend to be too much for certain customer profiles, like home cooks or students beginning their culinary classes. The cost, bulkiness, and upkeep needs make end grain cutting boards unfavorable, even though they have qualities professionals find amazing.

Source cutting boards from LeeKnives

We are a knife manufacturer with 30 years of experience. Having managed to carry this expertise to cutting boards, we can help you source the products your customers will enjoy using.

Check our selection of cutting boards with wood, grain, and size options. Once you find the product(s) you’re interested in, request a quote from here, and we’ll get back to you ASAP.