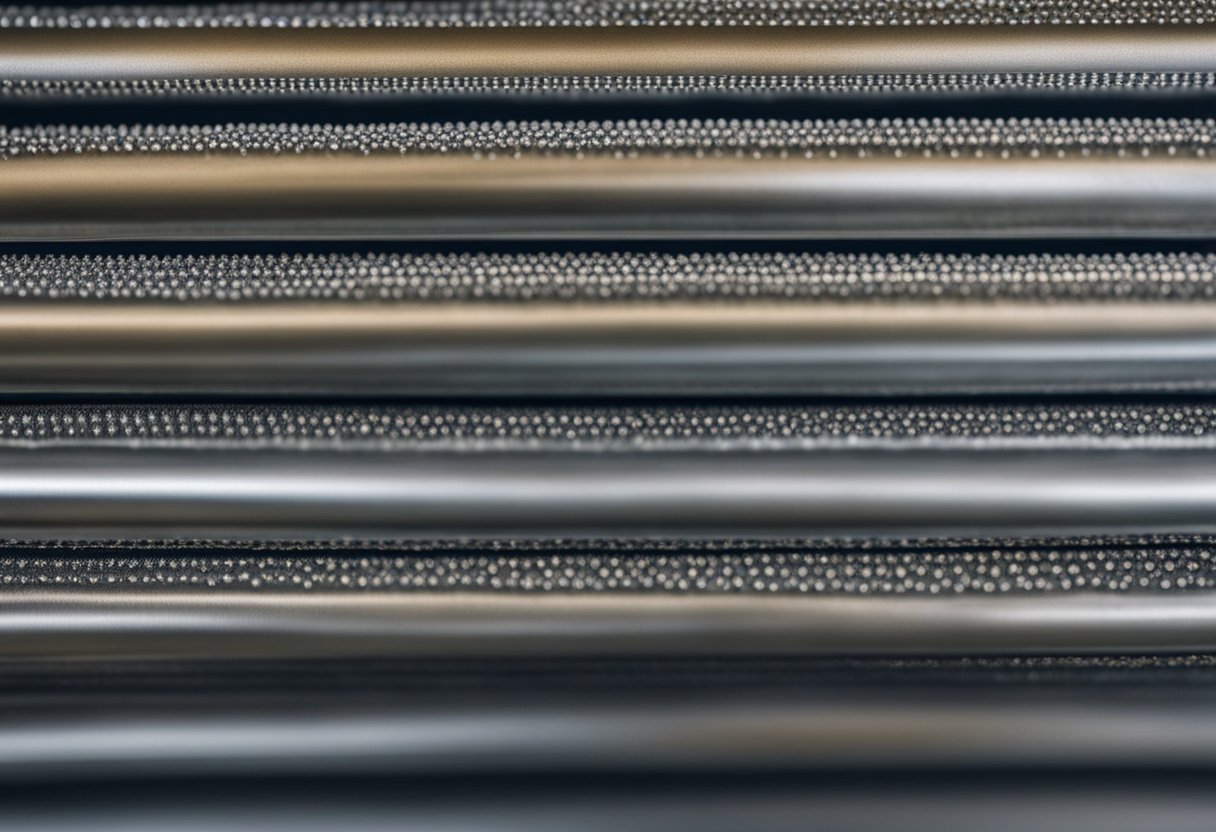

52100 steel is a high carbon low chromium alloy steel well-known for its impressive durability and resistance to abrasion and wear. This makes it an ideal material for manufacturing bearings, which are components crucial for the smooth operation of machinery by reducing friction between moving parts. The high carbon content gives 52100 steel a high degree of hardness and strength, which is why it’s also seen use in knife blades where sharpness and edge retention are paramount.

The combination of carbon and chromium in 52100 steel not only imparts hardness but also enhances its resistance to corrosion, albeit not as much as some other stainless steel. This is why protective coatings or care are important for knife blades or bearings exposed to harsh conditions.

As you explore the uses of 52100 steel, you’ll discover that its applications extend beyond bearings and knife blades. However, those two uses are among the most demanding and demonstrate the material’s high-performance characteristics. While bearings highlight the steel’s durability under high stress, knife blades showcase its potential for retaining a sharp edge over time, underlining the versatility and quality of 52100 steel in various industries.

What is 52100 steel?

52100 steel is a high carbon, low chromium alloy steel that offers high wear resistance and hardness. It is particularly known for its use in bearings.

The development of 52100 steel traces back to the early 20th century when it was initially used in bearings for military applications. Its properties were recognized to significantly extend the service life of these components. This steel became a standard material for the production of bearing races and balls due to its combination of hardness, dimensional stability, and resistance to wear and fatigue.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Chemical composition

- Carbon: 0.98% – 1.10%

- Chromium: 1.30% – 1.60%

- Nickle: 0.30%

- Manganese: 0.25% – 0.45%

- Silicon: 0.15% – 0.30%

- Copper: 0.20% – 0.30%

- Phosphorus: 0.025% – 0.030%

- Sulfur: 0.025%

- Aluminum: 0.05%

Examining the composition of 52100 steel reveals its considerable potential for hardness and edge retention when subjected to appropriate heat treatment. However, its rust resistance is notably compromised due to an insufficient chromium content. The addition of 0.05% aluminum in this steel is unconventional, as none of the previously discussed steels featured this element. It adds a bit of rust resistance property to 52100 steel.

Steel properties

In examining 52100 steel, you will find a balance of hardness, toughness, and wear resistance which contribute to its widespread use in high-stress applications like bearings and cutting tools. Your understanding of its characteristics is vital to appreciate why it’s a material of choice for precise and durable implements.

Hardness

52100 steel achieves a high degree of hardness through proper heat treatment, which typically brings it to a Rockwell hardness (HRC) of approximately 64. Hardness directly influences its ability to resist deformation and scratching. A high Rockwell hardness indicates that the steel can maintain a sharp edge for a longer period, which is crucial for edge retention in cutting tools.

Toughness and wear resistance

Despite its hardness, 52100 steel is also notable for its toughness – the ability to absorb energy and resist fractures – which enhances its overall durability. The additional chromium content is unusual for high carbon steels, which means 52100 forms smaller carbides that are tougher than most high carbon steel like 1095.

Alongside this toughness is remarkable wear resistance, implying the steel can withstand abrasion and extend the life of the implements made from it. Your tools made of 52100 steel should retain their functionality even under high stress and friction.

Rust resistance

52100 steel isn’t inherently rust-resistant and will require some maintenance to prevent corrosion. Your regular care and proper storage conditions can help mitigate rusting and ensure the longevity of the steel items. Applying protective coatings or treatments may be considered to improve the steel’s resistance to oxidation.

Ease of sharpening

While the high hardness of 52100 steel contributes to its remarkable edge retention, it can also make sharpening more challenging. However, with the appropriate sharpening tools and techniques, you can maintain a keen edge on your 52100 steel implements. The density and properties that contribute to its hardness help the steel hold a sharp edge once it is achieved.

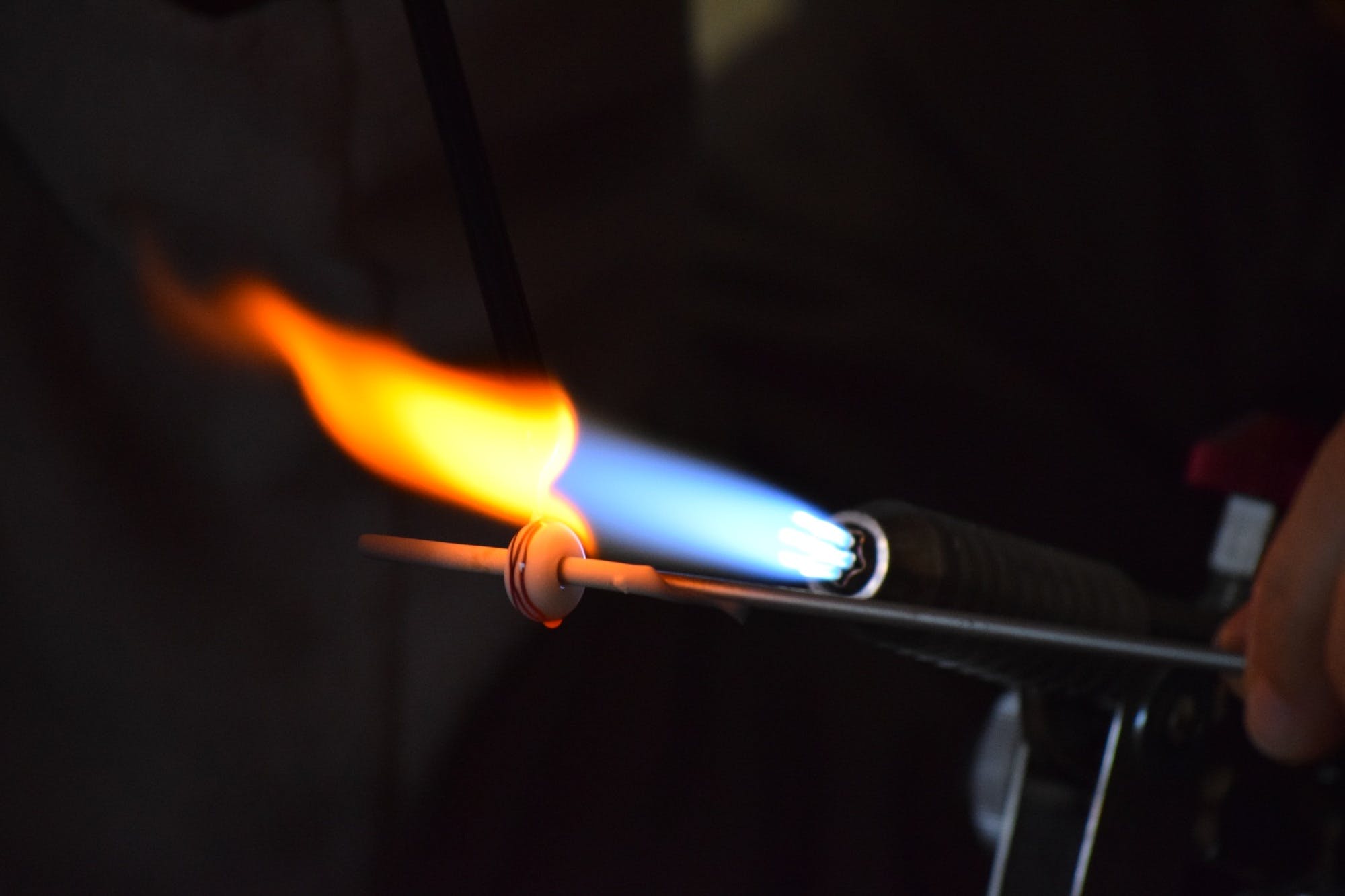

Heat treatment process

Heat treatment is a crucial step in processing 52100 steel to enhance its performance by altering microstructure and mechanical properties. Your understanding of the processes involved will guide you in choosing the best manufacturer if you want to work with this steel.

Annealing

Annealing a 52100 steel involves heating it to 1475-1525°F (800-830°C) and then slowly cooling it in a furnace or in still air. This process reduces hardness, relieves stress, and creates a more workable structure. For optimal results, ensure the steel reaches a fully annealed state by verifying a uniform temperature throughout the annealed bars.

Quenching and austenitizing

Austenitizing your 52100 steel is achieved by heating it to 1500-1550°F (815-843°C). This temperature range is critical to transform the steel into austenite. Immediately following austenitizing, you must quench the steel rapidly, typically in oil or air blast, to form martensite, a very hard structure. The rapid cooling is vital to prevent the formation of undesirable structures and obtain a hardening effect.

Tempering

After quenching, the 52100 steel will be exceptionally hard but also brittle. To reduce this brittleness, you must temper the steel by heating it to a lower temperature range between 300-500°F (150-260°C). This step develops the final balance between hardness and toughness. The temperature and time of tempering are pivotal; prolonged or higher temperatures can result in reduced hardness, so you should temper your steel according to the intended application’s requirements.

52100 steel vs other steel

52100 isn’t the most in-demand steel among knife enthusiasts, as there are other noteworthy equivalents and competitors. Prior to deciding on the steel for your knives, it’s crucial to carefully evaluate your options.

52100 steel vs. similar steel

52100 steel is frequently juxtaposed with other high-carbon low alloy steels such as 1095, 5160, blue super, and so forth. These steels share common characteristics, as they can all achieve relatively high hardness scores but exhibit poor rust resistance.

1095: 52100 offers notable advantages in terms of hardness. Both steels can attain high hardness levels, yet 52100 often stands out for its exceptional performance in this regard. Additionally, 52100 demonstrates superior wear resistance, making it a preferred choice in applications where durability is crucial.

5160: When pitted against 5160 steel, 52100 exhibits a similar capacity for achieving high hardness. However, 5160 is recognized for its excellent toughness, which can make it more suitable for certain applications requiring a balance between hardness and resilience. It’s essential to consider the specific demands of the intended use when choosing between these two steels.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

52100 steel vs. popular steel

While 52100 steel possesses commendable qualities, it is not the most prevalent choice for knife steel, facing robust competition from contenders like VG10, 8Cr13MoV, and ZDP-189. Let’s conduct a comparative analysis of these steels to discern their respective strengths and weaknesses.

VG10 steel is renowned for its excellent corrosion resistance and edge retention. In comparison to 52100, VG10 may have an advantage in terms of resistance to rust and staining. However, 52100 could outshine VG10 in achieving higher hardness levels, providing distinct advantages in specific applications.

8Cr13MoV is often chosen for its affordability and ease of sharpening. Compared to 52100, 8Cr13MoV might not reach the same level of hardness but compensates with ease of maintenance. 52100, conversely, could excel in scenarios where superior hardness and wear resistance are critical.

ZDP-189 is renowned for its exceptional hardness and edge retention. In contrast to 52100, ZDP-189 may exhibit similar or even superior hardness characteristics. However, 52100 might offer a different balance of properties, making it suitable for specific cutting tasks.

It is crucial to consider the intended use and priorities when selecting a knife steel. Although 52100 may not be the most popular, its unique combination of hardness and wear resistance can make it a compelling choice for specific applications. Each steel mentioned has its merits, and the ideal selection depends on factors such as corrosion resistance, ease of sharpening, and the specific demands of the cutting tasks at hand.

Should you choose 52100 steel for your brand?

When considering 52100 steel for your products, you should assess its qualities in relation to your brand’s needs. 52100 steel is renowned for its high carbon content, which contributes to its excellent wear resistance and high hardness. This type of steel is typically used in applications that demand these properties, such as in bearing and tool manufacturing.

Advantages of 52100 Steel:

- High wear resistance: Ideal for products that require durability against abrasion.

- High hardness: Can be heat treated to achieve high hardness levels, making it suitable for cutting tools.

- Retains shape well after heat treatment. This means it is less likely to cause problems at the manufacturer’s end.

Key considerations:

- Corrosion resistance: This steel is not as resistant to rust compared to stainless steels and may require protective coatings.

- Machinability: It can be challenging to machine once hardened; appropriate manufacturing processes must be in place.

Assess your product range and manufacturing capabilities to determine if 52100 steel aligns with the quality and performance standards of your brand. If your products are exposed to harsh working conditions or require a long service life without deformation, 52100 steel could be a match. However, consider the additional maintenance or coatings that may be necessary to prevent corrosion, especially if your products are used in moist or corrosive environments.

Manufacturing 52100 steel knives

Whether 52100 steel is for your brand ultimately hinges on a careful assessment of your product range and the capabilities of your chosen manufacturer. Given the significance of heat treatment for a steel like 52100, it becomes imperative to collaborate with a reputable and experienced manufacturer.

If you are struggling to find a reputable manufacturer, consider reaching out to LeeKnives. With a knife-forging legacy dating back to 1993, our expertise and services, including white-label options and customization, are designed to assist you in creating and selecting the finest knives for your brand. Contact us today for a quote, and let us help elevate your brand with precision-crafted knives that meet your unique specifications.