W2 steel is a part of water-hardening tool steels. The use of this steel is more prominent in machinery and other applications than knife blades. Nonetheless, a sizable number of knives are made from this steel, especially custom knives.

W2 can be heat treated easily using standard equipment and deliver unprecedented results. W2 steel is especially favorable among beginner and intermediate custom knife makers.

In this article, we’ll review the properties of W2 and reveal what to expect from this popular knife steel.

What is W2 steel?

W2 is a tool steel with multiple applications. Those that aren’t familiar with tool steels can take W2 as a standard high carbon, non-stainless steel. It has high hardness, achieved with the 0.85 to 1.15% carbon content. W2 also has small amounts of different elements that contribute to both hardness and toughness – more on the chemical makeup below.

W2 steel offers excellent qualities in uses where corrosion resistance isn’t the first concern. As it’s tool steel, W2 isn’t stainless but can resist corrosion somewhat okay. However, it can rust quickly if the maintenance elements are neglected in a humid environment or the kitchen.

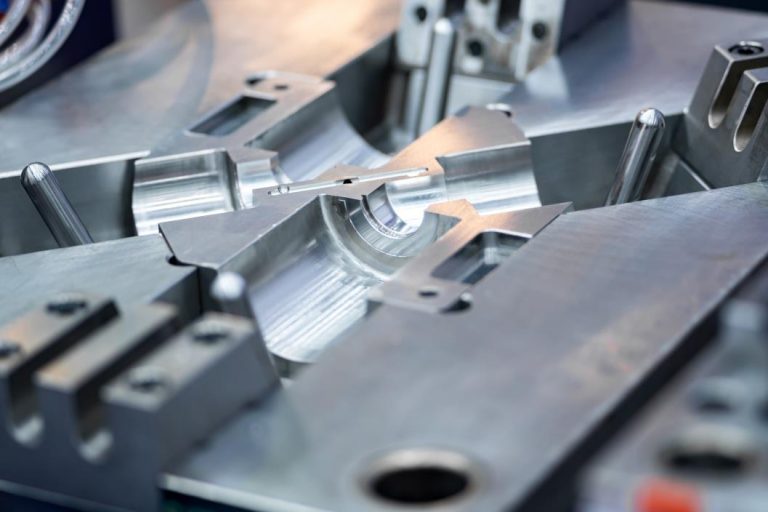

Today, we can see W2 steel across many industries other than knives. W2 is ideal for any tool prioritizing wear resistance, from blanking dies to woodworking instruments.

W2 steel chemical composition

- Carbon (C): 0.85 – 1.15%

- Chromium (Cr): 0.15%

- Vanadium (V): 0.15 – 0.35%

- Manganese (Mn): 0.10 – 0.25%

- Molybdenum (M): 0.10%

- Nickel (Ni): 0.20%

- Silicon (Si): 0.10 – 0.40%

- Tungsten (W): 0.15%

W2 steel properties

W2 steel’s composition includes various alloys that contribute to its properties. Here is everything you need to know about how W2 steel performs as a knife blade material to see if it will reach your needs.

Hardness

W2 steel is hard and can sustain this at exceptional levels. W2 steel is easy to heat treat, and knifemakers can play around with its hardness without facing severe consequences. W2 steel has a usual hardness of 65 HRc but can be anywhere from 62 HRc to 67 HRc. The hardness depends on the heat treatment done on W2 steel.

Tempering W2 steel to 62 HRc gives it better toughness, but this can affect other areas. The lowered hardness reduces wear resistance and edge retention. The knife makers can adjust this accordingly to fit the end user’s needs. The ability to set the hardness to different ranges is an explanation for why W2 is so widespread despite its possible downsides.

Corrosion resistance

As the list above explaining the chemical composition of W2 steel suggests, it barely has any chromium. The low chromium influences W2 steel’s ability to resist corrosion negatively. This tiny amount of chromium does more to the hardenability and wear resistance of the steel than corrosion resistance.

Still, the low amounts of molybdenum and tungsten somewhat contribute to corrosion resistance in addition to 0.15% chromium. It’s normal to expect poor corrosion resistance from W2 steel, but corrosion resistance won’t be an issue by implementing proper care methods.

It’s vital to identify if the industry you’re in favors corrosion resistance. Corrosion resistance is usually sought-after in kitchen cutlery but not as much for tactical knives. W2 steel isn’t the ideal knife material for people that aren’t so keen on caring for their knife blades. If your target customers are reluctant about this, it certainly won’t be the right choice.

For example, Japanese chefs have been utilizing high carbon steel knives for centuries that don’t offer much corrosion resistance. If you’re dropshipping and targeting professional chefs, your chances of success are higher.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Edge retention

Even when a W2 steel knife is on the lowest end of the hardness, it will provide outstanding edge retention. The edge will remain sharp for longer periods as the hardness increases. This trait of W2 allows many to forgive its underperforming corrosion resistance.

W2 steel knives not only hold a sharp cutting edge for long periods, but they can get very sharp. W2 steel has fine grains that provide an incredibly sharp, refined edge. Paired with the ability to sustain this for hours in fast-paced use, it makes the ideal knife material for many people.

Most steels have a balance to them where one feature tends to be insufficient; another is surprisingly more than adequate. Undoubtedly, W2 steel doesn’t have the corrosion resistance you would expect from stainless steel. Its ability to have a very sharp edge that stays that way for long periods makes up for it. This is a fundamental reason why W2 is so prevalent among knifemakers that want to forge their own blades.

Wear resistance

Wear resistance is important in knives to maintain their first-day appearance. A knife made from steel with poor wear resistance will get scratches even when honing the blade after some time. Issues like this aren’t prominent in W2 steel knives. They have adequate wear resistance that ensures it’s free from damages that can cause marks and scratches.

W2 steel’s wear resistance is enough for the regular utilization of knives and tools. Still, treating W2 steel knives with care is critical. Under stressed loads, noticing W2 steel wear down is typical.

Having a knife with a smooth blade is undoubtedly beneficial from an aesthetic point of view, but it comes with downsides, such as sharpening.

All blades get sharper by removing material from the edge. Since steel with good wear resistance can withstand this better, sharpening will be more difficult. W2 steel has adequate wear resistance to take some beating without showing damages so soon, but they will appear eventually. W2 is not a type of steel that we can put on par with steel that has proven wear resistance, like S110V or ZDP-189.

These remarks bring us to the ease of sharpening a W2 steel knife. It’s not a particular challenge but not a piece of cake either. It will take some elbow grease to sharpen W2 steel. Vanadium, high carbon amount, and tungsten make sharpening W2 steel knife blades slightly demanding.

It isn’t as easy to sharpen W2 steel as CPM154, AUS-6, and D2. However, W2 will keep its sharp edge for lengthier periods once pushing and pulling on a sharpening stone is over.

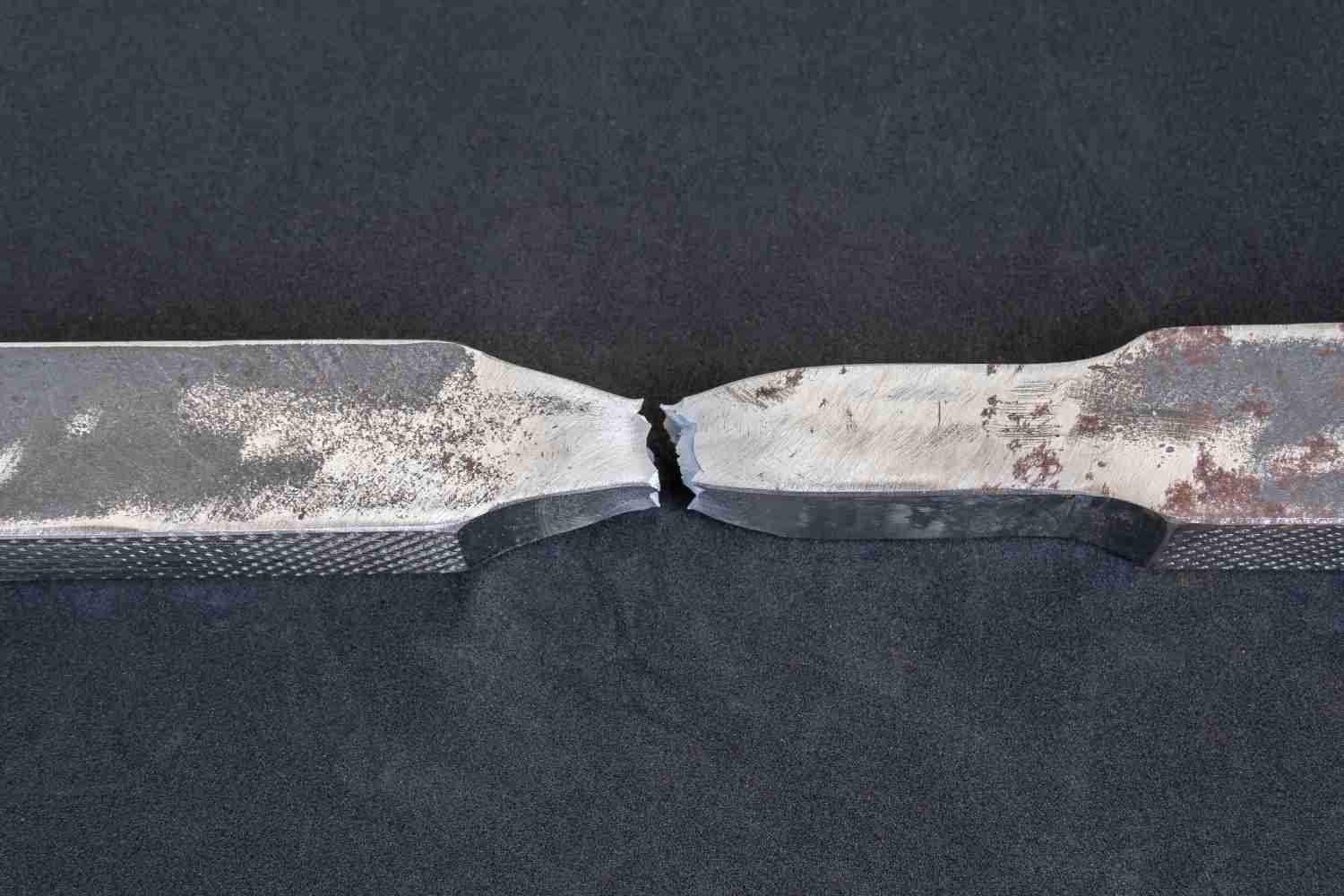

Toughness

The hardness and toughness usually don’t go hand in hand together. W2 steel has high hardness, and it’s expected to affect its hardness. While it certainly will take a beating quite well with good wear resistance, abusing W2 steel under heavy workloads can damage the blade.

The most common damage in knives to watch out for are the chips. Cutting and slicing everyday things that you’d cut with a knife won’t pose a problem. Nevertheless, cutting dense ingredients or wood with a W2 steel knife like hammering a nail can chip the edge unexpectedly. It’s essential to treat W2 steel knives with care to prevent chips and other damages.

If tempered to a low hardness, W2 steel can deliver better toughness. Lastly, the manganese found in W2 steel reduces its brittleness, improving toughness. Tungsten and nickel also contribute to W2 steel’s toughness.

Does W2 make a good knife material?

W2 steel makes a great knife material for users that prioritize edge retention and sharpness. A large profile of knife users favors these above all else. The superior edge retention and sharpness paired with easy heat treatment explains why W2 steel is popular for making custom knives.

W2 steel’s superb edge retention comes with a few downsides, though. If corrosion resistance is a prime concern, W2 steel won’t deliver the optimal results. As it is prone to rust, it’s vital for someone utilizing a W2 steel knife to look after the blade. It can rust rather quickly when this is overlooked, even for a moderate period.

Hamon on W2 steel

Other than the properties of W2 steel, knife enthusiasts know W2 for the hamon line on the blade. W2 steel has rapid quenching needs that make it possible for such designs. Hamon design occurs when there is a hardness difference on the blade.

While this adds character to a knife, it isn’t just for design purposes. The edge becomes harder for better retention, and the rest softer for better toughness.

Hamon design basically occurs by coating parts of the blade with clay so that the covered areas don’t cool immediately. Because the entire blade isn’t heat treated the same, the steel’s color doesn’t turn out the same across. This reveals a design similar to watermarks.

W2 steel vs. 1095

W2 and 1095 steels are very close to each other. In fact, there isn’t a difference between the two other than the added vanadium. This addition helps W2 in hardness and keeps a finer grain. These help W2 achieve better edge retention thanks to increased hardness and sharper edge due to the grain structure.

It’s not just the hardness and grain structure that vanadium affects. It also allows the W2 to show the hamon design much more clearly.

Summary and conclusions

W2 is a water-hardening tool steel that can reach high hardness levels. It can be tempered to increase toughness while maintaining considerably high HRc levels. The highlights of this steel are the incredible edge retention and razor-sharp edge.

From large knives to razor blades, W2 steel is utilized in many areas of cutlery and machines. W2 steel makes a good knife blade material aside from the poor corrosion resistance and subtle toughness. W2 steel is better fitted for users that don’t prioritize corrosion resistance and favor a sharp cutting edge that stays that way for long periods.

We provide OEM and ODM services to wholesalers, dropshippers, and those who plan on ordering large batches of knives. Need a quote? Come contact us now!