A knife is more than just a handle and a blade. Although it may look like that on the surface, there is more to it than just these two components.

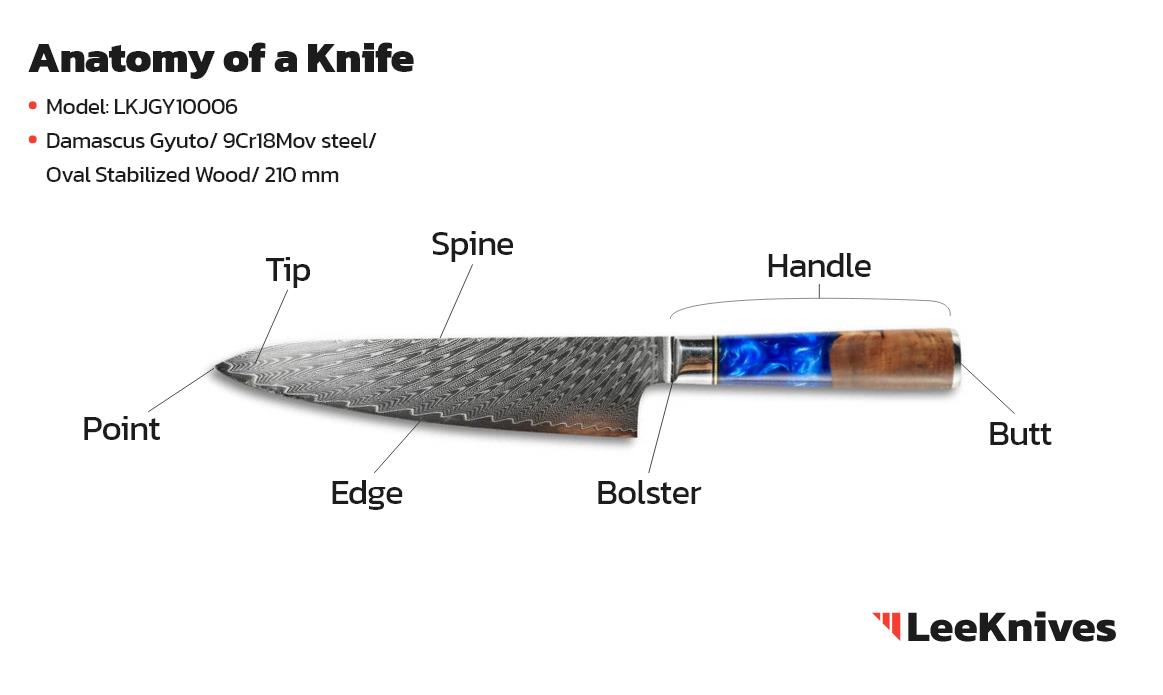

Each knife part serves a different purpose, allowing the cook to utilize it for a variety of needs. Namely, these parts are the butt, tang, handle, bolster, heel, edge, spine, tip, and point.

In this article, we’ll cover everything about these different knife parts and reveal how they can affect the user.

Before we dive right in, note that not every knife has all the parts mentioned above. For example, some knives don’t have a bolster. Furthermore, the knife’s components can also have variations, like the tang, which can come as full or half.

Point

It’s usual for anyone to mistake the point and the tip. The knife’s point is the part where the spine and the edge come together. This forms a sharp area useful for poking. Though the point isn’t helpful for actual cutting, it’s ideal for making slits and incisions.

Tip

Take a chef’s knife and place the belly straight on the cutting board. The edge that doesn’t make contact with the ground close to the point is the tip. This blade part is more for making precision cuts and delicate slicing. Depending on the cook’s preference, it’s also suitable for quick chopping with certain knives, like Santoku.

Spine

The spine is the dull, back part of the blade running from the handle to the point. Cooks can utilize the spine to apply more pressure when cutting dense ingredients or anything that requires additional force, like joints. The spine can tell a lot about a knife, whether it is forged or stamped, for example.

Edge

We’ve covered a knife’s most basic parts so far. It’s time to get to the more complex yet highly vital details.

The knife’s edge is where the knife cuts and pushes the ingredients away. While this sounds simple enough, there is more to itknife edges. Different types of knife edges can impact how the user operates with the knife.

Knife bevel (grind)

The knife bevel is the way the blade is ground that refers to how the blacksmith creates the cutting edge during the manufacturing process. Most blades are ground on both sides, making them a double bevel knife. These make up most of the knives in the market, but single bevel edge alternatives are also available.

Single bevel vs. double bevel

As their names suggest, single bevel knives are ground only on one side, and the other is on both.

The most notable difference between the two is that single bevel knives push the ingredients towards the ground side as the cook cuts. Because the edge is ground on both sides, the double bevel knives carry the food evenly. Since this creates a different cutting style, single bevel knives, whether for kitchen use or any other, aren’t ambidextrous.

The knife bevel can affect how the knife cuts entirely. There is more to discuss than just how it is ground.

Read more about knife bevel:

Granton edge

Additionally, there is the Granton edge. This type of knife edge is different from the others above. It isn’t a result of grinding, though. Granton edge knives have tiny air pockets that enable the blade to separate the food easily. Granton edge is primarily available in kitchen knives, especially Santoku knives made from German steel.

The easy separation from the blade makes Granton edge favorable to cooks cutting ingredients that often stick.

Read more about Granton edge:

Bolster

Also known as the fingerguard, a knife bolster is where the transition happens between the handle and the blade. However, not all knives have this feature. Almost all Japanese kitchen knives don’t have a bolster, except those with a western-style handle.

Full bolster

There isn’t a single type of bolster, the same as a knife’s edge, but the variations are only a few. A kitchen knife can have either a full or semi bolster. The full bolster runs from the spine to the edge, blocking the cook from touching underneath the heel. The full bolster gives extra protection but makes the knife heavier and more challenging to sharpen. The added weight can increase the shipping fees, especially when ordering knives in bulk.

Semi bolster

The semi bolster, on the other hand, is there from the handle to the start of the blade. Unlike the full bolster, it doesn’t affect the knife’s sharpening or cutting motion. It serves as a spacer between the two main components of a knife. The semi bolsters improve the balance significantly and give the knife more strength.

The bolster can affect the knife greatly by changing the way the cook holds the knife. It’s a critical knife part that every seller should consider to understand if it suits their customers.

Read more about knife bolster:

Handle

The handle is vital for several reasons. It’s the part where the user holds to operate the knife, after all. A blade fitted with the wrong handle won’t pass anything mediocre for the user, even if it has the sharpest blade.

That said, the user preferences determine the appropriate handle.

Handle materials

A variety of both natural and synthetic materials are used for making knife handle scales. Wood leads in popularity, aesthetics, and durability for most cooks, but other options like plastic and composite are also very prevalent.

Like how steel affects the blade’s performance – more on that below – the handle material adds many attributes to a knife. Wood handles are visually pleasing and durable, plastic handles are sanitary and affordable, and composite is in between. Knifemakers can utilize different materials to give similar attributes to a knife at different price ranges. For example, composite can serve as a more affordable alternative to wood.

Handle design

The two main handle designs are the Japanese wa-handle and western handle for kitchen knives. There are more handle design options with pocket knives, like the checkered patterns and clips, and more materials. The most popular materials for kitchen knives are wood, composite, and plastic.

For example, Japanese blades are very helpful for cooks, favored for their sharpness and ability to stay that way, but years of holding western handles make the wa-handle strange to control for some cooks. That’s why Japanese knife manufacturers also offer their products furnished with a handle familiar to them.

There is more to discuss on the materials and the designs as it’s such a vast topic.

Read more about knife handle:

Tang

The tang is the mostly invisible metal piece sandwiched between the handle scales. It extends from the blade to the handle, allowing the knifemaker to assemble the handle.

The tang also comes in two variations, like the bolster. It can either be full or partial.

Full tang

The full tang covers the entirety of the handle, usually with the same shape. It adds to the knife’s weight, which can be helpful when cutting dense ingredients. The full-tang knives are also more balanced, making it easier on the wrists when using them for extended periods.

Partial tang

The partial tang, also known as half tang, only extends halfway through the handle. The biggest downside to partial tang knives is that the handle can snap in half if the user neglects care or the knifemaker assembles it wrongly.

The easiest way to differentiate the two is by looking at the pins securing the handle. The full tang usually has two, and the partial tang has only one. Because of the fewer pins holding the handle in place, more adhesive is applied to secure it with partial tangs.

Additionally, some tangs go all the way back to the butt in a slimmer profile. This type of knife tang is known as the stick or rat-tail tang. These are basically identical to the partial tang as the overall weight at the handle is the same.

The tang affects the knife in many other ways. The difference becomes much clearer when comparing the two primary tang types in depth.

Read more about knife tang:

Butt

An often overlooked part of a knife’s anatomy, the butt, can help the user in rather different ways. Most knife butts stick out towards the bottom in a downward hook. This section allows the user to securely hold the knife in place, especially when exerting force to cut.

Some also use this area to pound meats and other ingredients, but it isn’t recommended. Utilizing the butt repeatedly like this can loosen the tang, resulting in the handle separating.

Knife steel

The tang, bolster, blade design, etc., are indeed crucial factors. However, the steel used for forging the blade defines the actual attributes. A knife won’t deliver satisfying qualities without the appropriate steel for the primary purpose and the user’s needs.

Carbon steel

Carbon steel is generally harder than stainless steel, The superior hardness helps them keep their sharp edge for longer durations. Added with easy sharpening, they are popular in knife market and favored by enthusiasts. However, the lack of chromium in their composition makes them more susceptible to rust and the elevated hardness more brittle.

Carbon steel examples:

- ZDP-189

- 65mn

- SG2

- W2

- Shirogami&Aogami

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Stainless steel

For various reasons, stainless steel is the most common and popular choice for making knives. These steels are usually easier to machine and incredibly resistant to rusting and other oxidation forms. They are also more durable as they are typically soft, at least compared to most carbon and high carbon steel.

Stainless steel examples:

- x50Cr15MoV

- AUS-8

- 440C

- VG-10

- ATS-34 (154CM)

Read more about knife steel:

How does the steel affect the knife’s performance?

The steel’s properties directly affect everything about the knife, from how it cuts to whether it’s suitable for specific tasks. In simpler terms, the following are the most critical properties of any knife steel that can greatly impact the knife’s features.

Hardness

The steel’s hardness improves edge retention but can also increase brittleness at higher levels. Carbon amount in the composition defines the hardness of steel. It’s what contributes to hardenability the most.

There isn’t a perfect hardness for knives, as it’s up to the user’s liking. Under the Rockwell hardness test, most kitchen knives are around 54 to 58 HRc. This sweet spot has a good balance between edge retention, brittleness, and durability.

Toughness

The toughness refers to the steel’s ability to absorb impact and energy without breaking, shattering, or other damage occurring. It’s essentially the durability of the steel.

Hardness and toughness have opposite influences on this. Steel with high hardness tends to have lower toughness and vice versa. Since toughness largely determines the durability, it’s a vital consideration for knifemakers.

Corrosion resistance

The knife’s ability to resist oxidation is critical, especially for home cooks. The chromium is the highlight of any steel in this matter. Usually, steel with high chromium amounts is better at resisting oxidation.

Still, simply increasing chromium won’t make the steel resist corrosion more. The other alloys also matter. A good example of this is ZDP-189, which has 20% chromium, enough to make it resist corrosion better than most steel, but the 3% carbon overshadows it. That said, the chromium to carbon ratio also needs to be considered.

Wear resistance and sharpening

All knives get dull eventually, requiring them to be sharpened using a whetstone. The two most important factors in sharpening ease are wear resistance (ability to resist material loss) and carbide size.

A knife made from steel with high wear resistance will take more time to create a new edge using a whetstone. At the same time, wear resistance will improve edge retention. Although this is a good trade-off, wear resistance and sharpening ease work similarly to hardness and toughness.

Customize a knife with LeeKnives

By now, you should have an idea about everything that can go into the anatomy of a knife. It’s time to think about the needs of your customers and design the perfect knife to accommodate their preferences.

We offer OEM services at LeeKnives, where you have complete control over the design and materials of the entire knife. You can learn more about OEM services here.

Already have the full picture? Request a quote with your specifications, and we’ll get back to you ASAP.