Sharpening stones are the most effective tools to refine an edge. Whether a knife is beyond dull or needs a kick of sharpness, an appropriate sharpening stone can deliver the best results. However, there isn’t a single type of whetstone.

There are century-old oil stones, popular Japanese water stones, ceramic stones that are the newest addition, diamond stones that sharpen aggressively, and many more. With all these options, knife store owners and managers are just as likely to get confused as their customers.

In this article, we’ll break down the types of sharpening stones to help you figure out the ones that make ideal products to sell. Before you read, consider bookmarking this page for use, so you never find yourself lost before adding new sharpening supplies to your inventory.

Types of sharpening stones

There isn’t a single type of sharpening stone. Although how the sharpening stones work and the way they are utilized are identical, the outcome may vary. To help us choose the right products, we can classify different types of whetstones into four categories.

- Water stone: Water stones need to be submerged in water to fill the air bubbles and lubricated with a splash of water.

- Oil stone: Like water stones, they need a coat of oil on the surface before sharpening. Luckily, they don’t need to be submerged as water stones.

- Diamond stone: This type of whetstone isn’t entirely made from diamonds. Diamond stones have microscopic diamond crystals on steel plates. These sharpening stones feature by far the coarsest surface.

- Ceramic stone: Ceramic stones can be made from different abrasive. Common choices include aluminum oxide and silicon carbide.

The above classification doesn’t give detail much as it leaves the features of different types of whetstones quite broad. We need to cover the different types of whetstones more exhaustively to give you a better understanding.

Buy Wholesale Knife Accessories and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

India stone (aluminum oxide)

The naming of India stones may be misleading. The material used for making these whetstones doesn’t come from India, nor is it mined from quarries. It’s an artificial ceramic material for making sharpening stones.

Aluminum oxide sharpening stones offer plenty of benefits to knife users. Those who need to give a refined edge to their blades at a fast rate can benefit from aluminum oxide whetstones the most.

India stones remove material from a knife’s edge, similarly to polishing it. This leads to a longer sharpening session, but they give knives a very fine edge – often without requiring a finishing stone later. Yet, any knife can get a more refined edge after an India stone.

Highlights of India stones (aluminum oxide)

- Helps refine the edge without a polishing stone

- It can take sharpening with oil or water, appropriate for users looking for a whetstone that needs a particular lubricant.

Silicon carbide

Like India stone, silicon carbide is an artificially made material used for making sharpening stones. Silicon carbide’s biggest difference from aluminum oxide is its coarseness. It removes material from knife edges more aggressively, but still not as much as diamond stones.

Silicon carbide whetstones generally require water as a lubricant and tend to wear off fast due to being brittle. It crumbles easily with every stroke, producing more slurry that adds to the abrasiveness. As a result, silicon carbide sharpening stones sharpen a knife quickly but also wear down faster.

However, the increased coarseness is a step up from India stones, which can make it difficult to achieve a polished edge.

Highlights of silicon carbide whetstones

- Sharpens fast and efficiently without damaging the blade due to coarseness at a microscopic level.

- Ideal for users looking for a simple sharpening stone.

- It’s easy to clean and maintain.

Arkansas stone (novaculite)

Arkansas stone is a widely recognized, natural sharpening stone material. It leads the way in oil stones with a wide range of grit sizes. You can sell fairly coarse or very fine stones made from Arkansas stone. Overall, it has enough variety to cover the sharpening needs of average users.

The best part about novaculite whetstones is that they don’t wear down fast and sharpens knives similarly to polishing them.

In a way, Arkansas stones polish knife edges as it sharpens. A knife sharpened with an Arkansas stone doesn’t need a finishing stone as much, leaving it already somewhat polished. Nevertheless, moving to a finishing stone after novaculite will result in a better, finer edge.

This type of sharpening stone is a perfect fit for shops that appeal to a mixed group of customers looking for a simple yet effective sharpening stone.

Highlights of Arkansas stone

- Arkansas stone polishes the knife while it sharpens, making the use of a finishing stone optional.

- This type of whetstone doesn’t wear down as fast. A novaculite whetstone lasts significantly longer than aluminum oxide and silicon carbide alternatives.

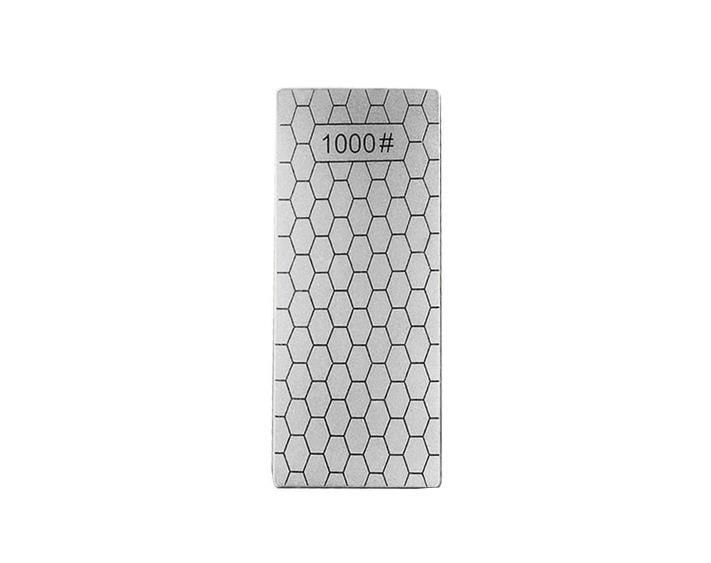

Diamond stone

Diamond whetstones aren’t like the others, separating themselves with how they are constructed. Instead of abrasive materials forming a block with a binder, diamond stones have crystallized diamond particles on a metal sheet.

Some of these sharpening tools have holes in them that help with cleaning. These diamond stones, however, are better for sharpening lengthy blades, as the tip of small blades can get stuck, resulting in damaging the knife.

Since diamond is one of the hardest materials (the hardest naturally occurring material), it produces the coarsest whetstone.

If you intend to sell diamond-coated whetstones, note that these aren’t for everyone. More often than not, knife enthusiasts that are experienced in sharpening turn to this type of sharpening stone. Diamond whetstones aren’t recommended for beginners, as they remove the most material from the edge at the fastest rate.

Highlights of diamond stones

- They sharpen knives aggressively, removing the most material from the edge with each stroke.

- Diamond stones save time when sharpening wear-resistant blades, but using a finishing stone afterward is a must to smooth out the edge.

- Diamond sharpening stones come in various grit sizes despite being the coarsest. There are even diamond finishing stones that often require a lubricant to polish knife edges, similar to others.

Lubricant substance for whetstone

The lubricant to use when sharpening a knife with a whetstone mostly depends on the manufacturer. However, there are some exceptions to this.

Novaculite stones often require oil while diamond stones often don’t need any lubricant. Ceramic whetstones, on the other hand, might or might not require a lubricant. Ceramic sharpening stones that don’t need a lubricant are essentially identical to honing rods but in the shape of a sharpening stone.

How to use a whetstone?

Using a whetstone is straightforward in three simple steps:

- Prepare the whetstone.

- Hold the knife at its sharpening angle or what you desire.

- Begin gently stroking it from heel to tip.

Although very simple on the surface, sharpening with a whetstone is a challenging and often messy task. That’s why honing rods and sharpeners are more popular among average users. There are many small details that every sharpener needs to adhere to produce the finest results.

Some examples would be sharpening the pointed tip separately, feeling the sharpening angle with every stroke, and using shoulders to move the blade.

Refining the cutting edge with a sharpening stone

The approach you take to sharpening and refining the cutting edge of a knife is somewhat the same. After all, you move the blade over the whetstone, removing material. Yet, sharpening and polishing the edge are different tasks.

Once the knife gets sharpened on a medium or coarse whetstone, it needs to be polished using a finishing stone. This is what refines the edge, removing the burr and other tiny flaws.

Refining the cutting edge is best done with a finishing stone. The higher the grit (must be above 3,000), the more refined the cutting edge, though it will take longer to bring the knife there.

Buy Wholesale Knife Accessories and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

A simple guide to selling whetstones

Finding ways to choose the right whetstones and other sharpening products to sell doesn’t have to get complicated. A simple look at the knives you sell and the profiles of customers that walk into your store or visit your online shop can tell enough.

Not every whetstone is appropriate for sharpening all types of knives. For example, sharpening a knife made from X50CrMoV15 knife steel with a diamond stone is likely to damage the edge. It’s better to sharpen knives like this with low wear resistance and hardness using India or Arkansas stones.

At the same time, these sharpening stones can pose challenges when sharpening knives with high wear resistance and hardness.

It all comes down to what type of whetstone suits the knife being sharpened, which we’ve detailed in this article.

If you’ve made up your mind or are in the process of doing so, check our whetstones and other sharpening supplies. You can purchase wholesale products from us – directly from the manufacturer at rates below the market. Click here to request a quote – LeeKnives is ready to partake in growing your business.