When choosing knife handles for your product line, materials matter, not just for durability or looks, but for how well the knives perform in your customers’ hands.

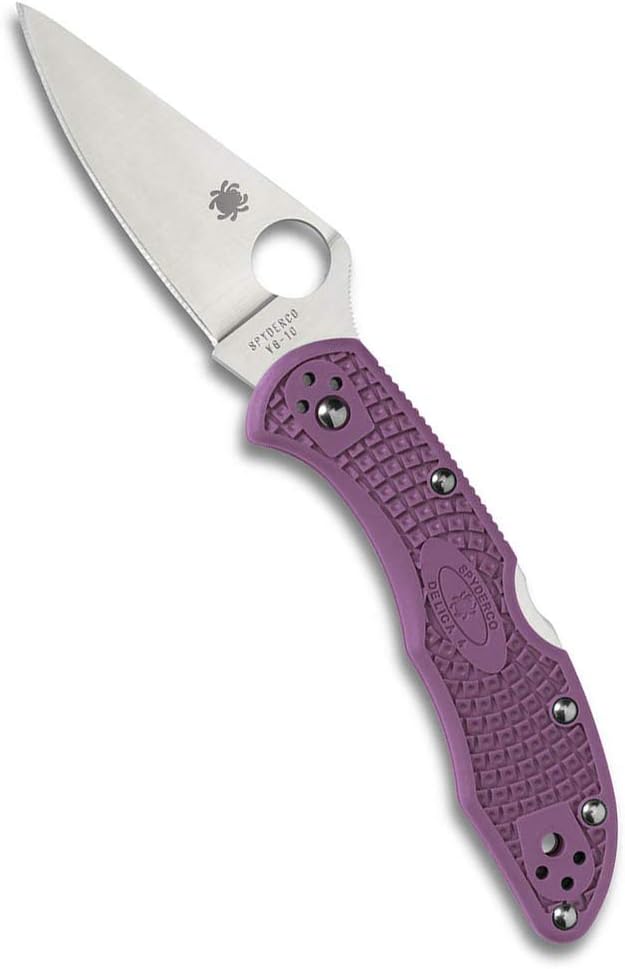

One material that often flies under the radar is FRN, or Fiberglass Reinforced Nylon.

It may not have the flash of carbon fiber or the warmth of wood, but it’s earned a solid reputation among knife makers for being tough, affordable, and incredibly practical.

In this guide, we’ll break down what FRN is, how it compares to other popular materials like G10, and why it might be worth considering for your knife catalog.

What is FRN?

FRN stands for Fiberglass Reinforced Nylon, a tough, high-strength plastic composite widely used in knife handles.

It’s created by injecting glass fibers into a nylon polymer, resulting in a material that is both lightweight and durable.

Unlike natural materials like wood or bone, FRN doesn’t warp, crack, or absorb moisture.

And compared to premium synthetics like G10 or carbon fiber, it delivers a reliable balance between cost and performance, making it a popular choice for high-utility knife designs.

Why is FRN popular in knife making?

FRN has gained popularity across the knife industry for several practical reasons:

1. Performance in demanding environments

FRN is resistant to wear, moisture, and chemical exposure. It doesn’t need polishing or oiling and holds up in both kitchen and outdoor conditions with minimal maintenance.

2. Lightweight but strong

It offers an impressive strength-to-weight ratio, making it ideal for knives where comfort, balance, and agility matter without compromising on toughness.

3. Excellent grip

FRN can be molded with aggressive textures or bi-directional patterns, providing reliable grip even when hands are wet or greasy. This makes it especially useful in cooking, camping, or tactical use.

4. Cost-effective for brands and buyers

Its lower production cost allows manufacturers to keep prices down while maintaining durability. For sellers, this means broader appeal to entry-level buyers, first-time knife users, or those looking for a dependable everyday tool.

5. Ergonomic and mold-friendly

Because it’s injection-molded, FRN can be easily shaped into contoured, hand-friendly forms without extra machining.

This gives designers more freedom to create functional knives that feel good to hold, even at scale.

How strong is a FRN knife handle?

FRN might be lightweight and cost-effective, but it’s far from weak. Its strength lies in the way it’s engineered and the real-world performance it delivers.

1. Reinforced for rigidity

FRN is short for Fiberglass Reinforced Nylon, which means it’s a nylon base infused with glass fibers.

These fibers dramatically improve the material’s rigidity and impact resistance, giving it more structure and durability than traditional plastics.

2. Withstands everyday abuse

FRN handles are designed to withstand hard use. They don’t warp, crack, or chip easily even when exposed to frequent impact, drops, or stress. The material is also highly resistant to:

- Moisture and humidity

- Chemical exposure

- UV and temperature extremes

This makes FRN a great option for both indoor and outdoor environments — from the kitchen sink to field conditions.

3. Holds up better than many alternatives

Compared to wood, FRN won’t swell, shrink, or splinter. And while it may not feel as premium as G10 or carbon fiber, it offers comparable durability at a lower cost, making it one of the best materials in terms of value per dollar.

Why this matters for sellers

- Fewer customer complaints – FRN resists the kind of wear that often leads to returns.

- Longer product lifespan – Less maintenance means more satisfied buyers over time.

- Reliable for entry- to mid-tier knives – It’s the perfect balance of durability and affordability for mass-market or utility-focused catalogs.

Pros and cons of FRN knife handles

Fiberglass Reinforced Nylon (FRN) may not be the flashiest handle material, but it earns its spot in many knife catalogs for solid reasons. Below, we break down the trade-offs:

Pros

- Tough and durable – FRN is impact-resistant, corrosion-proof, and handles rough use well, making it ideal for utility and EDC knives.

- Lightweight – Despite its strength, FRN is very light, which makes for easier handling and less user fatigue.

- Low maintenance – It doesn’t absorb moisture, crack, or warp, and cleans up easily — perfect for both kitchens and outdoor conditions.

- Cost-effective – Far more affordable than G10, micarta, or carbon fiber, ideal for budget-friendly or high-volume product lines.

- Excellent grip – Molded textures on FRN handles offer great traction, even when wet or greasy.

Cons

- Less premium feel – FRN lacks the tactile appeal and polish of more expensive materials, which some buyers may associate with lower quality.

- Limited customization – Fewer options for aesthetic variation compared to layered synthetics like G10.

- Slight flexibility – In larger knives, FRN can exhibit minor flex under pressure. Not ideal for users who want ultra-rigid handles.

FRN vs G10: Which one should you offer your customers?

FRN (Fiberglass Reinforced Nylon) and G10 (fiberglass laminate) are two of the most widely used synthetic handle materials, both praised for their durability, water resistance, and cost-efficiency.

But depending on your customer base and price point, one may be a better fit than the other.

Here’s how they compare:

| Feature | FRN (Fiberglass Reinforced Nylon) | G10 (Fiberglass Laminate) |

| Weight | Very lightweight | Slightly heavier and denser |

| Durability | Tough and flexible; resistant to impact and chemicals | Extremely strong and rigid; less prone to flex |

| Grip | Molded textures offer great grip, even when wet | Can be machined for aggressive, high-traction patterns |

| Aesthetic | Basic molded finishes; limited customization | Highly customizable (colors, layering, contouring) |

| Maintenance | Low-maintenance; doesn’t absorb moisture | Also low-maintenance; may feel rougher when unpolished |

| Cost | Lower cost; great for entry-level and bulk orders | Higher cost; better for mid-range and premium models |

| Best For | Utility knives, EDC, beginner kitchen sets | Collector knives, tactical models, or premium kitchen lines |

Why FRN can be a smart choice for your knife catalog

FRN may not have the visual prestige of G10 or carbon fiber, but from a business standpoint, it’s one of the smartest handle materials you can stock.

It’s affordable, durable, and highly versatile across categories, a reliable choice for knife sellers looking to balance performance with profit.

1. Affordable without feeling cheap

FRN offers reliable performance at a fraction of the cost of high-end materials. Its durability means fewer product returns, while its price point gives you more flexibility to create competitively priced SKUs.

2. Performs well in both kitchen and outdoor environments

FRN is resistant to moisture, heat, and impact, all qualities that matter in both culinary and tactical applications.

Whether it’s constant washing in a home kitchen or unpredictable conditions in the field, FRN holds up without cracking or swelling.

3. Scales well for OEM and private label brands

As an injection-molded material, FRN is fast and cost-effective to produce at scale.

It’s a strong choice for private label businesses looking to build out a knife line with consistent quality and low overhead.

4. Customizable textures and grip patterns

While FRN may not offer the visual layering of G10, it can still be textured in a variety of ways, bi-directional, checkered, or grooved.

This adds value for customers while giving your product line more grip variety.

5. Branding and differentiation potential

Molded handles can be designed with signature shapes or embossed logos, giving your products a unique identity without high tooling costs.

For budget or utility knives, this is a simple way to stand out.

6. Reliable for entry-level and utility products

FRN fits naturally into lower to mid-tier price segments. It’s ideal for starter kits, outdoor gear, kitchen essentials, and any application where low maintenance and solid grip matter more than aesthetics.

In short, FRN is a dependable workhorse of a material. If your catalog includes practical, high-utility knives, or you’re looking to expand into that space, FRN is a smart addition to consider.

Final thoughts: Should you add FRN knives to your inventory?

FRN might not be the flashiest handle material, but it hits a sweet spot between price, performance, and practicality, especially for utility-focused knives.

It’s lightweight, highly durable, water-resistant, and performs well under pressure.

For knife sellers looking to offer budget-friendly options that still deliver serious value, FRN deserves a place in your catalog.

It may not appeal to every buyer, especially those shopping for aesthetics or high-end design, but for customers who prioritize function, FRN knives can be a strong seller.

Ready to Source FRN Knives?

At LeeKnives, we help businesses like yours source knives with the right materials for your market – whether that’s affordable utility knives or premium collector pieces.

We assist with bulk orders, private labeling, and product curation based on your customer base.

Contact us today to request a free quote and start building your catalog with confidence.