A sharp knife is always safer and more enjoyable to use. Some knives keep their sharpness for long; some for less. Regardless, all lose it eventually and will do better with a sharper edge.

Sharpening and honing are two main ways knife users utilize to sharpen up a blade. It’s natural to think honing rods and sharpening supplies work the same. After all, they make knives sharper, and as long as it gets there, it doesn’t matter how, right? That would skip many details, such as how the blade gets sharp, what the user does to get there, and the longevity of the newly achieved sharpness.

Sharpening and honing are two different things that have similar yet varying outcomes, though both make cutting a tomato easier. The differences are in the tools and how they accomplish a sharper edge. Here is everything you need to know about the differences between sharpening and honing.

Honing

Honing requires a honing rod and provides a quick fix to restoring a knife’s sharpness. The stick of honing rods is generally made from hard steel, with a stop at the handle that prevents the knife from going past it.

You take the knife, hold it against the stick at an appropriate angle and rub the edge – more on how to hone and sharpen a knife below. How this process makes the edge sharper is quite simple.

A sharp knife’s cutting edge is perfectly aligned. This alignment goes out of order in the early stages of dulling, and the knife begins to struggle with cutting.

Honing can do two things to this damaged edge. It can realign the rugged sections, but more often than not, it removes the rolled edge. How this happens has to do with the kind of wear the edge undergoes and that comes with the type of honing rod utilized.

Types of honing rods

Steel honing rods realign the rolled edge that withstands the wear. When it can’t, which is likely to happen, it removes it as the rolled edge withstanding it isn’t very probable. Steel honing rods do this through adhesive wear, not by abrasion. That happens with ceramic and diamond-coated honing rods.

Ceramic honing rods do what steel equivalents do faster and perhaps better. Since ceramic is much harder than steel, it’s abrasive enough to wear off the material as opposed to bumping into the rolled edge and erasing it. As a result, the abrasion creates a secondary bevel that helps with cutting. This micro bevel takes the knife’s sharpness a step further and enables the knife to cut more efficiently for longer.

Diamond honing rods are a step up from their ceramic equivalents. It sharpens up a knife the same as a ceramic honing rod, but much faster and more efficiently. Diamond wears the most material from the edge, accomplishing what ceramic honing rods can with 10 strokes in just a few. However, since they are the coarsest, they wear down a lot of material from the apex bevel, requiring the users to utilize sharpening products sooner.

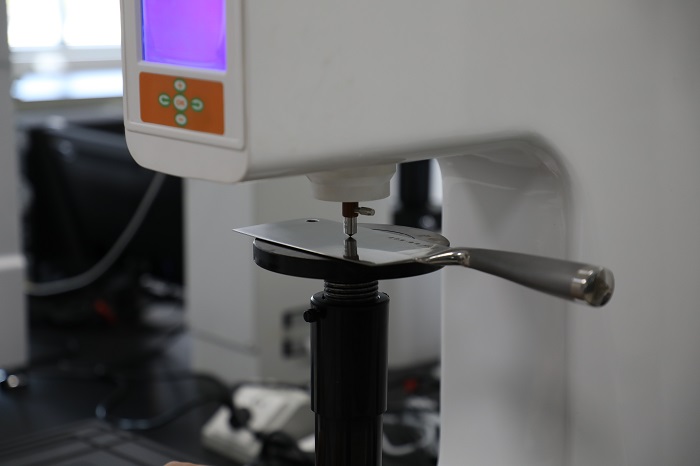

Sharpening requires a whetstone (sharpening stone) or a sharpener. Sharpening a knife gives it an entirely new cutting edge. The friction wears out the old, dull edge and replaces it with an untouched one. The goal of sharpening is to reset the edge to make it as sharp as the factory. Honing, on the other hand, wears out only the apex bevel, not the entire edge.

While the outcome of sharpening is somewhat better than honing, sharpening can’t be a daily routine. Sharpening a knife removes significantly more material from the blade, and if your customers do this whenever the knife loses its sharpness, they will soon run out of a blade to cut. That said, honing should come first. When it doesn’t satisfy, it’s time to take it to a whetstone or sharpener.

You can sell two primary tools for your customers to sharpen their blades – a whetstone or a sharpener.

A sharpener is very straightforward to use, but it has some limitations. Whether handheld or electric, sharpeners sharpen knives at a specific angle, which can cause issues. For example, Japanese kitchen knives are sharpened at around 15 degrees. This sharpening angle may not work with some sharpeners. Also, most sharpeners don’t work with single bevel knives.

Sharpening a knife with a whetstone is quite tricky, but with enough practice, it will allow your customers to achieve the best results. With whetstones, users have full control over how they want to sharpen their knives, sharpening angle, and edge polis. For example, sharpening a knife with an 8,000 grit whetstone will give it a scary sharp edge, while a 400 grit whetstone makes it sharp quickly.

As for which one to sell, we recommend both. This way, you’ll have the necessary products to cover the sharpening needs of general and professional users – as well as those in between. Luckily, we have low MOQs for sharpening products. Knife stores of all sizes can benefit from our affordable pricing on our wholesale products.

Key differences between sharpening and honing

- Although both make knives cut better, honing and sharpening don’t have the same outcome. Honing refines the rolled, dull edge, while sharpening creates a brand-new cutting edge.

- Honing takes fewer steps, less time, and is straightforward to begin. Sharpening is a multi-step process, involving sharpening and polishing the edge that isn’t so beginner-friendly.

- Honing and sharpening need different tools, with whetstones offering more variety.

Now that you have a good grasp of honing and sharpening differences, let’s go over how to hone and sharpen.

Buy Wholesale Sharpening Tools and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

How to hone a knife?

Regardless of what type of honing rod you use, the principles of using one are the same. Here is how to hone a knife, step-by-step.

- Hold the honing rod in your non-dominant hand.

- Bring the knife’s edge to the honing stick and have a feel for the angle by stroking the blade gently. When the knife is held at the correct angle against the honing rod, it will glide without any pushback.

- Once at the correct angle, move the honing rod and the knife in opposite directions simultaneously. You can also move the blade only while keeping the honing rod stationary.

- Repeat the process on both sides about ten to fifteen times each and test the knife’s sharpness.

Additionally, you can hold the honing rod in a fixed position, like keeping it upside down over the kitchen countertop. As long as the honing angle is correct, how you go about it doesn’t matter.

How to sharpen a knife

Since there isn’t a single tool for sharpening, we’ll explain how to sharpen a knife with a whetstone and a sharpener. How you utilize these are different, but the purpose of sharpening is the same – to wear down the blade to expose a new cutting edge.

With a whetstone

Sharpening with a whetstone often requires two ranging grit sizes. That’s why most whetstones have two sides; one for sharpening and the other for polishing.

- First, if a water stone is what you have, submerge it in water until the air bubbles stop coming out. This is for filling the air bubbles with water. Oil and diamond stones don’t require such action before use.

- Lubricate the surface and begin sharpening with the coarse side of the whetstone and hold the knife at the appropriate sharpening angle.

- Stroke the blade from heel to tip while maintaining the same angle. You can also sharpen parts of the blade separately, like from heel to belly and belly to tip.

- Flip the whetstone and repeat the process. The finer surface will polish the edge and remove the burr and other impurities caused by the coarse whetstone.

With a sharpener

Whether handheld or electric, sharpening with a sharpener is the same. The only difference is one will require you to use more elbow grease.

- Keep the sharpener on a stable surface.

- Bring the knife’s heel, the closest part to the handle, into the slot.

- With light pressure, pull the knife towards yourself.

If it’s an electric sharpener, doing this a few times should be enough, as the motors inside do most of the work for you. With handheld sharpeners, you’ll want to do this about five to ten times. The same as whetstones, most sharpening stones have coarse and fine slots. Always start with the coarse opening first and finish off with the finer one.

You can include these simple steps for sharpening and honing in the maintenance manuscript of the products you sell.

Tips on maintaining knife sharpness

Knives are simple tools with simple care needs. Keeping one in top condition isn’t demanding. Still, here are additional tips on maintaining knife sharpness you can pass on to your customers.

- Cutting surface: Kitchen knives must be utilized on an appropriate cutting surface. Often, marble, glass, and stone cutting boards get the attention of customers, but they are notorious for dulling knives quickly. The best cutting board materials are wood, plastic, and rubber in this regard. We recommend all knife shops highlight these to keep customers happy.

- Purpose: Always advise your customers on not going beyond the intended purpose of their knives, like using a chef’s knife to cut

- Maintenance: A cared knife will last longer, not just in sharpness, but as a whole. Overlooking upkeep will require the knife to need more push to cut, taking all the potential sharpness away from it. Handing out a card with crucial knife care tips and dos and don’ts is enough to inform customers to make them come back satisfied.

Buy Wholesale Sharpening Tools and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

What honing/sharpening products to include in your list of products?

As you can take from this article, sharpening and honing are essential to have optimal sharpness. Sharpening isn’t available every time the user needs to get a kick of sharpness. That’s where honing plays a big role, enabling them to get sharper with little effort.

For knife stores of all sizes, it’s best to sell both honing rods and sharpening products. Start browsing our sharpening supplies from here. We have various types of honing rods, diamond sharpening stones, dual-sided whetstones, and more.

LeeKnives can help your business grow by outsourcing the products any knife store needs. Click here to request a quote and to learn more about our products.