Looking for the world’s most revered blade steel? Tamahagane steel isn’t just metal—it’s the soul of traditional Japanese samurai swords, crafted with 1,000 years of hand-forged expertise. This guide dives into that story: the ancient techniques that make tamahagane one of the world’s rarest steels, why it’s so expensive, and what sets it apart from every other blade material out there — so you can understand why it’s the gold standard of blade steel. Whether you’re a knife collector, a bladesmith enthusiast, or simply curious about ancient craftsmanship, you’ll walk away with a deep dive into this iconic material.

What Is Tamahagane Steel?

Tamahagane steel (The word tama means ‘precious‘, and the word hagane means ‘steel‘) is a rare, high-carbon steel exclusively crafted for making authentic Japanese katana (samurai swords) and other traditional nihonto (Japanese blades). Unlike mass-produced modern steels, it’s made using a centuries-old hand-forging process that prioritizes purity, grain structure, and balance—traits that make it irreplaceable for crafting blades with both sharpness and resilience.

Exclusive Identity

Crucially, tamahagane steel is not a “generic” high-carbon steel. It’s defined by its production method (traditional tatara forging) and purpose (authentic nihonto). Mass-produced samurai sword replicas rarely use real tamahagane—they rely on cheaper alternatives like 1095 steel or stainless steel. For a blade to be considered a true “katana,” it must be forged from tamahagane.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

History of Tamahagane Steel

Tamahagane steel’s story is intertwined with Japan’s feudal history and samurai culture, spanning over a millennium of refinement.

1. Origins: Heian Period (794–1185)

The earliest forms of tamahagane emerged during the Heian Period, when Japanese blacksmiths began experimenting with local iron ore (satetsu) and wood-fueled forges. Initially, the steel was crude—impure and inconsistent—but it laid the groundwork for later innovations. Blacksmiths discovered that folding and hammering the steel removed impurities, a technique that would become central to tamahagane production.

2. Refinement: Kamakura to Edo Periods (1185–1868)

- Kamakura Period (1185–1333): As samurai warfare became more prevalent, demand for stronger blades grew. Blacksmiths perfected the “tatara” (clay furnace) design, allowing for longer smelting times and better temperature control. This era produced some of Japan’s most famous katana, all forged from early tamahagane.

- Edo Period (1603–1868): Peace reduced the need for combat blades, so blacksmiths shifted focus to craftsmanship. They refined the tamahagane process—extending smelting to 72 hours, optimizing fuel blends, and standardizing folding techniques. This period is considered the “golden age” of tamahagane, with bladesmiths like Masamune (known as the “Sword Saint”) creating masterpieces still revered today.

3. Cultural Symbolism

For samurai, tamahagane steel was more than a material—it was a symbol of honor, courage, and identity. A katana’s tamahagane blade was believed to hold the samurai’s “spirit,” and caring for the blade was a sacred ritual. Even today, tamahagane remains a cultural touchstone, representing Japan’s dedication to traditional craftsmanship in a modern world.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Key Properties of Tamahagane Steel

Tamahagane steel’s unique properties come from its composition and forging process, making it stand out from modern industrial steels.

| Component | Content Range |

| Carbon | 1.0% – 1.5% |

| Iron | 98.0% – 98.5% |

| Sulfur | <0.02% |

| Phosphorus | <0.02% |

| Silicon | 0.2% – 0.5% |

| Manganese | 0.2% – 0.5% |

1. Exceptional Edge Retention

Thanks to its high carbon content (1.0%–1.5%) and fine grain structure, tamahagane holds an ultra-sharp edge longer than most steels. A well-honed tamahagane katana can slice through bamboo or silk with minimal effort, and it retains this sharpness even after repeated use—unlike cheaper steels that require frequent sharpening.

2. Balanced Hardness and Toughness

Most high-carbon steels are brittle (prone to cracking if dropped), but tamahagane avoids this. Its layered grain structure (from folding) and low impurities give it flexibility: it can bend slightly under impact (e.g., clashing with another blade) and spring back without breaking. On the Rockwell Hardness Scale (HRC), tamahagane scores 58–60—hard enough for sharpness, but not so hard that it’s brittle.

How Is Tamahagane Steel Made?

The production of tamahagane steel is a labor-intensive, 72-hour process that relies on ancient techniques—no industrial machinery is used. It’s one of the few remaining examples of pre-industrial steelmaking, and only a handful of master blacksmiths in Japan still practice it.

Step 1: Gather Raw Materials

- Satetsu: Iron-rich sand mined from Japanese rivers. Unlike iron ore from other countries, satetsu has low impurities, making it ideal for tamahagane.

- Kizuna: Hardwood fuel (usually oak or chestnut). It burns slowly, generating the high, steady heat needed for smelting.

- Mokume: Straw ash mixed with clay. It lines the tatara furnace, insulates heat, and helps remove impurities from the iron.

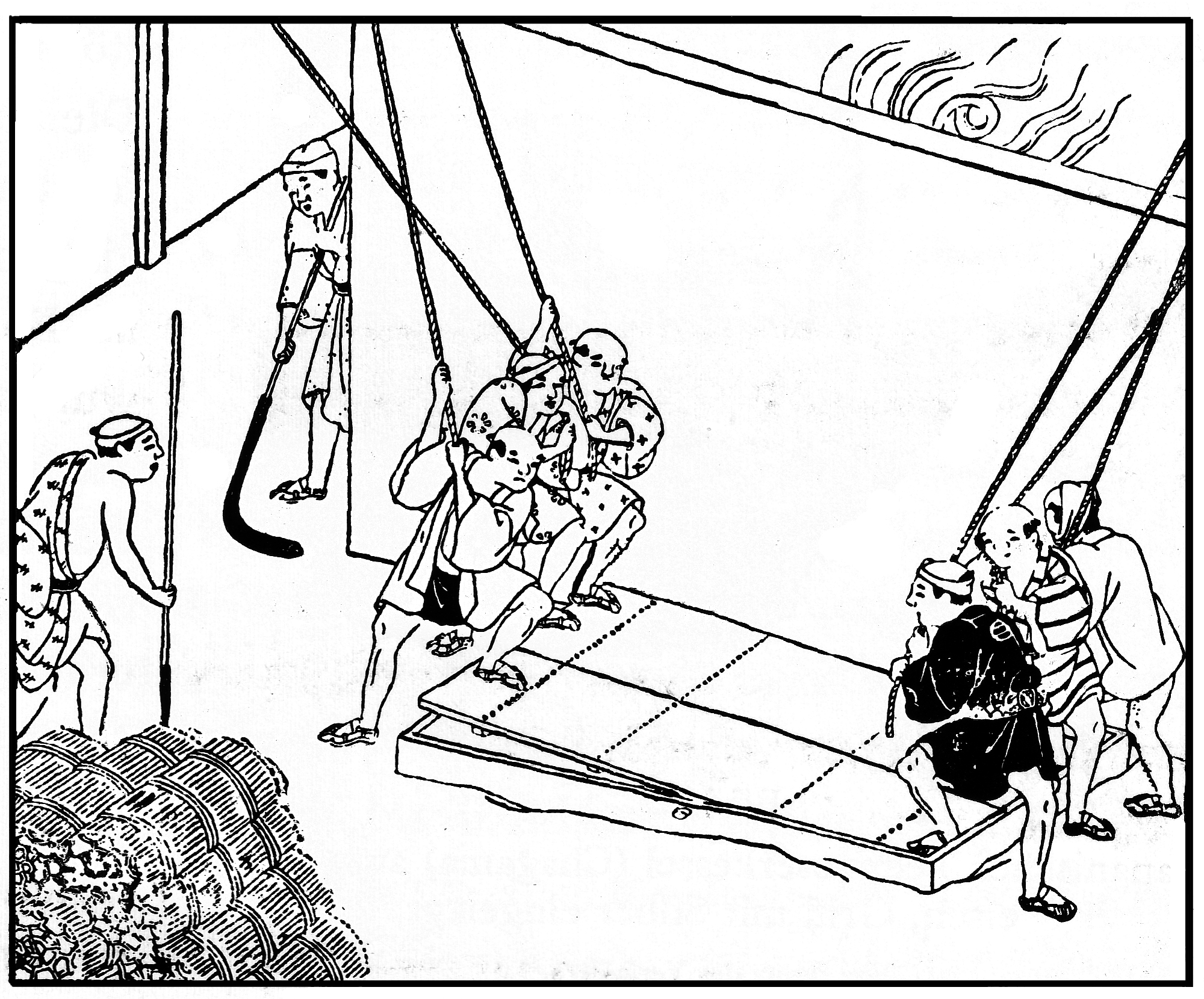

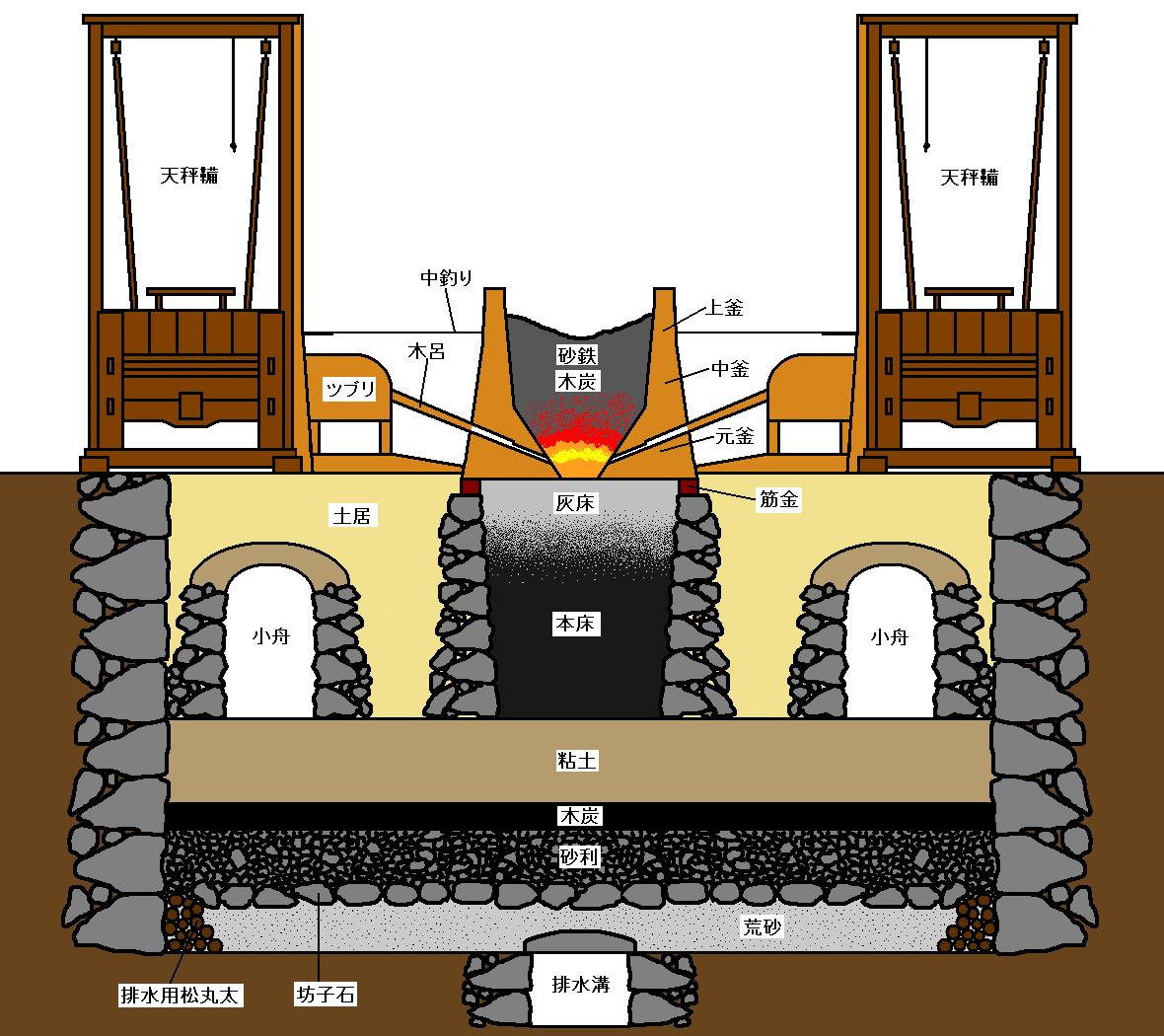

Step 2: Smelt in the Tatara Furnace

The blacksmith builds a temporary tatara furnace (about 1.5 meters tall) from clay and mokume. They fill it with alternating layers of satetsu and kizuna, then light the fire. The furnace burns for 72 consecutive hours, with the blacksmith monitoring temperature (kept at ~1,300°C) and adding fuel/ore as needed. During smelting, the iron in satetsu reacts with carbon from the wood, forming steel.

Step 3: Select High-Quality Steel

After 72 hours, the furnace is broken apart. Inside is a large, porous steel block called a “tamahagane mass.” The blacksmith carefully splits this mass, sorting it into two types:

- Kitaeji: The highest-quality steel, with uniform carbon content and few impurities. This is used to make the katana’s blade.

- Hagane: Lower-quality steel with higher impurities. It’s used as “filler” during forging or discarded.

Step 4: Fold and Forge (Kitae)

The kitaeji is cut into smaller pieces, which are heated and folded repeatedly. This step—called “kitae”—is critical:

- Folding: The steel is folded 10–15 times, creating 2¹⁰ to 2¹⁵ layers (1,024 to 32,768 layers). Each fold presses out impurities (like slag) and distributes carbon evenly.

- Hammering: Between folds, the steel is hammered into shape, aligning its grain structure for strength. The blacksmith must work quickly—if the steel cools too much, it cracks.

The result is a block of tamahagane steel with a fine, layered grain structure—perfect for forging a katana.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

What Is Tamahagane Steel Used For?

Tamahagane steel’s primary use is crafting authentic Japanese katana, but its rarity and beauty have expanded its applications to modern collectibles and luxury items.

1. Authentic Japanese Katana (Nihonto)

This is tamahagane’s core purpose. Today, only a few master bladesmiths (certified by Japan’s Nihon Token Kai, or Japanese Swordsmith Association) are licensed to make tamahagane katana. These blades are not just weapons—they’re works of art, with prices ranging from $10,000 to over $1 million for antique or master-crafted pieces. They’re sought after by collectors and museums worldwide.

2. High-End Custom Knives

In recent years, top knife makers (both in Japan and abroad) have started using small batches of tamahagane to create luxury EDC knives and chef’s knives. These knives appeal to enthusiasts who want the performance of tamahagane in a more practical form. For example, a tamahagane chef’s knife might cost $2,000–$5,000, but it offers unmatched sharpness and durability for professional chefs.

3. Cultural Crafts and Jewelry

Small pieces of tamahagane steel are also made into cultural crafts and jewelry. Examples include:

- Tamahagane pendants: Polished steel pendants engraved with traditional Japanese motifs (e.g., dragons, cherry blossoms).

- Decorative blades: Miniature katana replicas (6–12 inches long) used as desk decor or gifts.

- Sword fittings: Tamahagane is sometimes used to make tsuba (guard plates) or menuki (decorative handles) for high-end katana.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Tamahagane Steel vs. Other High-Quality Steels

Tamahagane is often compared to modern premium steels like 1095 (high-carbon) and S35VN (stainless powder steel). Here’s how they stack up:

| Feature | Tamahagane Steel | 1095 High-Carbon Steel | S35VN Stainless Steel |

|---|---|---|---|

| Production Method | Traditional tatara forging (hand-made, 72h) | Industrial smelting (mass-produced) | Powder metallurgy (industrial) |

| Carbon Content | 1.0%–1.5% | 0.95%–1.05% | 0.35% |

| Hardness (HRC) | 58–60 | 56–58 | 58–61 |

| Edge Retention | Excellent | Good | Very Good |

| Toughness | High (flexible) | Low (brittle) | Very High (resists impact) |

| Rust Resistance | Low (needs oiling) | Low (prone to rust) | High (stainless) |

| Aesthetic Value | Natural hamon/hada (unique) | Plain finish | Plain or acid-etched |

FAQ

1. Is tamahagane stronger than regular steel?

“Strength” depends on the type of steel, but tamahagane is tougher than most regular steels (like 1095). It balances hardness (for sharpness) and flexibility (for impact resistance), making it more durable in scenarios like blade-on-blade contact. However, modern stainless steels (like S35VN) are stronger in terms of rust resistance and impact tolerance for everyday use.

2. Why is tamahagane so expensive?

Tamahagane’s high cost comes from three factors:

- Rarity: Only a few blacksmiths make it, and each batch takes 72 hours to produce.

- Labor: The process is entirely hand-made—no machines can replace the skill of a master blacksmith.

- Cultural Value: Tamahagane is tied to samurai culture and craftsmanship, making it a “collectible” material rather than a commodity.

3. Can tamahagane steel be used for everyday knives?

It’s possible, but not practical. Tamahagane is rare and expensive—an everyday tamahagane knife would cost thousands of dollars. It also rusts easily (needs regular oiling) and is too valuable to risk damaging with daily tasks (e.g., cutting vegetables). Modern steels like S35VN are better for everyday use.

4. Where can I buy real tamahagane steel blades?

Authentic tamahagane blades are sold through:

- Certified Japanese sword dealers: Look for dealers affiliated with the Nihon Token Kai.

- Auctions: Prestigious auctions (e.g., Sotheby’s, Christie’s) occasionally sell antique tamahagane katana.

- Direct from master bladesmiths: A few Japanese bladesmiths (e.g., Kunihira Kawachi) sell custom tamahagane blades, but wait times can be 1–2 years.

5. Does tamahagane steel rust easily?

Yes. Tamahagane is a high-carbon steel with no chromium (the element that makes steel “stainless”), so it rusts if exposed to moisture. To prevent rust, wipe the blade with a dry cloth after use and apply a thin layer of sword oil every few months.

Conclusion

Whether you’re a collector or simply appreciate traditional craftsmanship, tamahagane steel embodies the peak of Japanese blade-making—where history, precision, and artistry unite. From ancient samurai swords to modern chef’s knives, its legacy continues to inspire those who value quality and authenticity.

At Leeknives, we bring that same spirit of craftsmanship into modern production. We specialize in OEM, private label, and wholesale knife manufacturing for brands and retailers across Europe and North America. If you’re looking to source high-quality knives from China, request a free quote here and let’s craft your next collection together.