Whether you’re a knife enthusiast hunting for your next EDC tool or a seller looking to expand your product line with high-demand blades, Whether you’re searching for a reliable daily carry (EDC) tool, a precise blade for crafting, or looking to expand a tool collection with versatile options, the Wharncliffe blade’s timeless design offers unique value. This guide breaks down every detail you need to understand its strengths, match it to your needs, and make informed decisions. If you want to learn more about this unique design, Let’s dive in!

What Is a Wharncliffe Blade? Core Design Traits That Define It

The Wharncliffe blade stands out for two non-negotiable design features that shape its performance—these details aren’t just technicalities, but the reason it excels at specific tasks and remains a popular choice across decades:

1. Edge Profile & Blade Shape

Its most recognizable trait is a fully straight cutting edge that runs parallel to the knife’s handle (no curved “belly” like drop-point or clip-point blades). This design delivers two critical benefits:

- Uniform contact with materials: When slicing paper, leather, or fabric, the entire edge stays in touch with the surface, eliminating ragged edges or uneven cuts—ideal for tasks where precision matters.

- Consistent pressure distribution: For push-cuts (e.g., carving wood, scoring cardboard, or opening stacked packages), force spreads evenly across the edge, preventing slipping or accidental damage to the material.

This straight edge also simplifies sheath or pocket removal: it slides in and out without catching on fabric or sheath liners, making it a practical choice for daily carry.

2. Tip & Spine Structure

- Spine: Tapers gradually from the handle to the tip (not sharply angled like a clip-point), creating a slim yet sturdy profile that balances control and durability.

- Tip: Positioned in line with the cutting edge (not raised) and sharpened to an acute angle (typically 20–25°). This design boosts stability when applying downward pressure—perfect for piercing thick materials (cardboard, leather, foam) or scraping kindling—while remaining stronger than thin clip-point tips (less likely to bend or break during light use).

For example: A Wharncliffe tip won’t flex when pushing through a leather wallet, but it’s not built for heavy-duty prying (unlike a tanto’s reinforced tip)—a key distinction for matching it to the right tasks.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

History of Wharncliffe Blade-From 19th-Century Utility to Modern Favorite

A blade’s legacy adds credibility—and the Wharncliffe’s 200-year history proves it’s not a passing trend, but a design built for long-term utility:

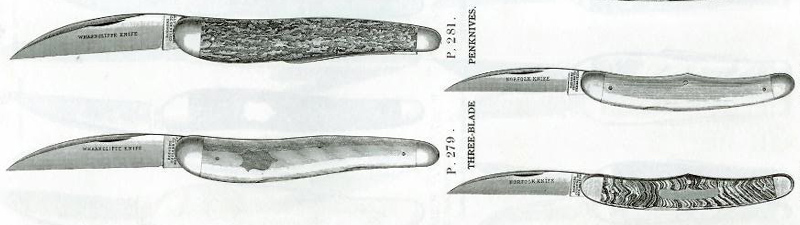

- Origins (1820–1832): The blade was developed by English nobleman Lord Wharncliffe and Archdeacon Corbett, who sought a better alternative to the flimsy “spring-knives” of the era. They partnered with Sheffield-based cutler Joseph Rodgers & Sons (a legendary name in British knife-making, known for quality craftsmanship) to produce the first batch in 1832.

- Early Use: It began as a “gentleman’s utility tool”—used for carving, woodworking, and everyday tasks—thanks to its straight edge and durable tip, which balanced precision and practicality.

- Modern Resurgence (1990s): Tactical knife expert Michael Janich popularized the Wharncliffe as a versatile blade for tactical and emergency use, highlighting its control for slicing and precision. This led to iconic models like the Spyderco Yojimbo 2, turning it into a staple for EDC enthusiasts, crafters, and outdoor users alike.

This lineage matters: a design that has adapted from 19th-century workshops to 21st-century pockets is a sign of lasting functionality.

Wharncliffe Blade Pros & Cons: Real-World Use Cases

To decide if a Wharncliffe blade fits your needs, it’s critical to weigh its strengths against its limitations—all tied to how you’ll actually use it:

Pros

- Unmatched precision for straight cuts: Ideal for tasks like trimming leather for wallets, cutting model kits, slicing stacked paper, or dressing small game—any scenario where uneven edges ruin results.

- Easy to sharpen: A straight edge works with basic whetstones, sharpening rods, or even portable sharpeners (no need to “follow a curve” like with drop-point blades). This is a huge plus for beginners or anyone who needs to touch up the edge in the field.

- Stable, durable tip: The in-line tip handles piercing and downward pressure without bending—great for opening tough packages, scraping bark for kindling, or piercing foam sleeping pads.

- Smooth carry & deployment: The straight edge slides effortlessly in and out of pockets, sheaths, or tool belts, making it a low-fuss EDC option.

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Cons

- No belly – poor for sweeping cuts: It struggles with tasks that rely on a curved edge, like chopping vegetables, skinning large game, or slicing through thick, fibrous materials (e.g., thick rope in one pass). A drop-point or chef’s knife is better here.

- Limited heavy-duty piercing: While the tip is strong for light use, it’s not reinforced like a tanto’s—avoid using it to pierce metal, thick plastic, or car seats (common in emergency scenarios).

- Not built for chopping: Its slim spine can’t handle the force of splitting small logs or chopping through branches. Stick to a bushcraft knife or hatchet for heavy outdoor tasks.

Wharncliffe vs. Other Blade Shapes

The Wharncliffe isn’t the only blade shape out there—here’s how it compares to four popular alternatives, so you can match it to your specific needs:

Wharncliffe vs. Drop Point

Drop Point has a curved “belly” and slightly downward-sloping tip, excelling at versatile sweeping cuts (e.g., skinning, chopping). Wharncliffe’s fully straight edge and in-line tip can’t match that curve for gliding through thick materials—but it beats Drop Point for precise, clean straight cuts (e.g., trimming leather, cutting kits).

Wharncliffe vs. Tanto

Tanto features a reinforced, angular tip and short angled edge, built for heavy-duty piercing (e.g., breaking metal). Wharncliffe has a long straight edge and non-reinforced (but durable) tip—great for smooth straight cuts, but far less effective than Tanto for high-pressure piercing.

Wharncliffe vs. Sheepfoot

Sheepfoot shares a straight edge but has a rounded, blunt tip (safe for tasks like food prep, avoiding accidental punctures). Wharncliffe’s sharp, in-line tip adds piercing ability—trading Sheepfoot’s safety for more versatility (e.g., opening packages, scraping kindling).

Wharncliffe vs. Clip Point

Clip Point has a slim, upward-clipped tip (good for micro-detailing like small carving) but bends easily. Wharncliffe’s sturdier in-line tip and longer straight edge lack that fine detail ability—but are more durable for everyday straight cuts (e.g., opening boxes) without bending.

Is a Wharncliffe Blade Good for Self-Defense?

From a practical standpoint, the Wharncliffe is not the top choice for self-defense—here’s why, and when it might work as a backup:

- Limitations: Its straight edge and in-line tip don’t deliver the “stopping power” of a tanto or drop point. It’s hard to make deep, disabling cuts, and its understated design lacks the visual deterrence of tactical blades.

- Backup Use: If trained, it can work for controlled slicing (e.g., cutting through restraints) or as a last-resort tool. But if self-defense is your primary goal, prioritize a blade built for that purpose (e.g., a tanto or fixed-blade drop point).

Buy Wholesale Knives and Start Scaling up with Us Today

Contact us and connect with a sales rep to get a free quote.

Final Thoughts

If you’ve been searching for a blade that delivers reliable precision for daily EDC, light outdoor tasks, or detailed crafting—something that lives up to the Wharncliffe’s signature straight-edge accuracy and durable tip—Leeknives is here to help. As a brand specializing in quality knives, we offer both OEM customization and wholesale services tailored to how you’ll use your Wharncliffe Blade. No matter if you’re picking one for personal use or sourcing in bulk, we align with what makes this blade stand out—so you get a tool that works as hard as you need it to.

Frequently Asked Questions

For everyday carry, should I choose a folding or fixed-blade Wharncliffe?

Folding is almost always better for EDC. The straight edge makes folding models compact when closed—they fit easily in pockets or small bags, and they open smoothly without getting stuck. Fixed-blade Wharncliffes are great for specific jobs (like heavy-duty crafting or backcountry trips), but they need a sheath to carry safely, which adds bulk to daily use.

In daily and outdoor scenarios, what tasks let a Wharncliffe Blade shine the most?

Its straight edge is the star here—daily, it’s perfect for opening packages cleanly (no torn cardboard), trimming leather or fabric (no rough edges), or peeling fruits. Outdoors, it excels at light jobs like processing small game (e.g., dressing poultry), scraping kindling for fires, or piercing foam sleeping pads. It’s not built for heavy chopping, but for tasks that need steady, precise cuts, it’s hard to beat.